AERCO Electronic Controls System (ECS) User Manual

Page 45

Electronic Control System (ECS) and Type CXT-E Valve

7. TROUBLESHOOTING

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 45 of 82

AC-105

OMM-0003_0D

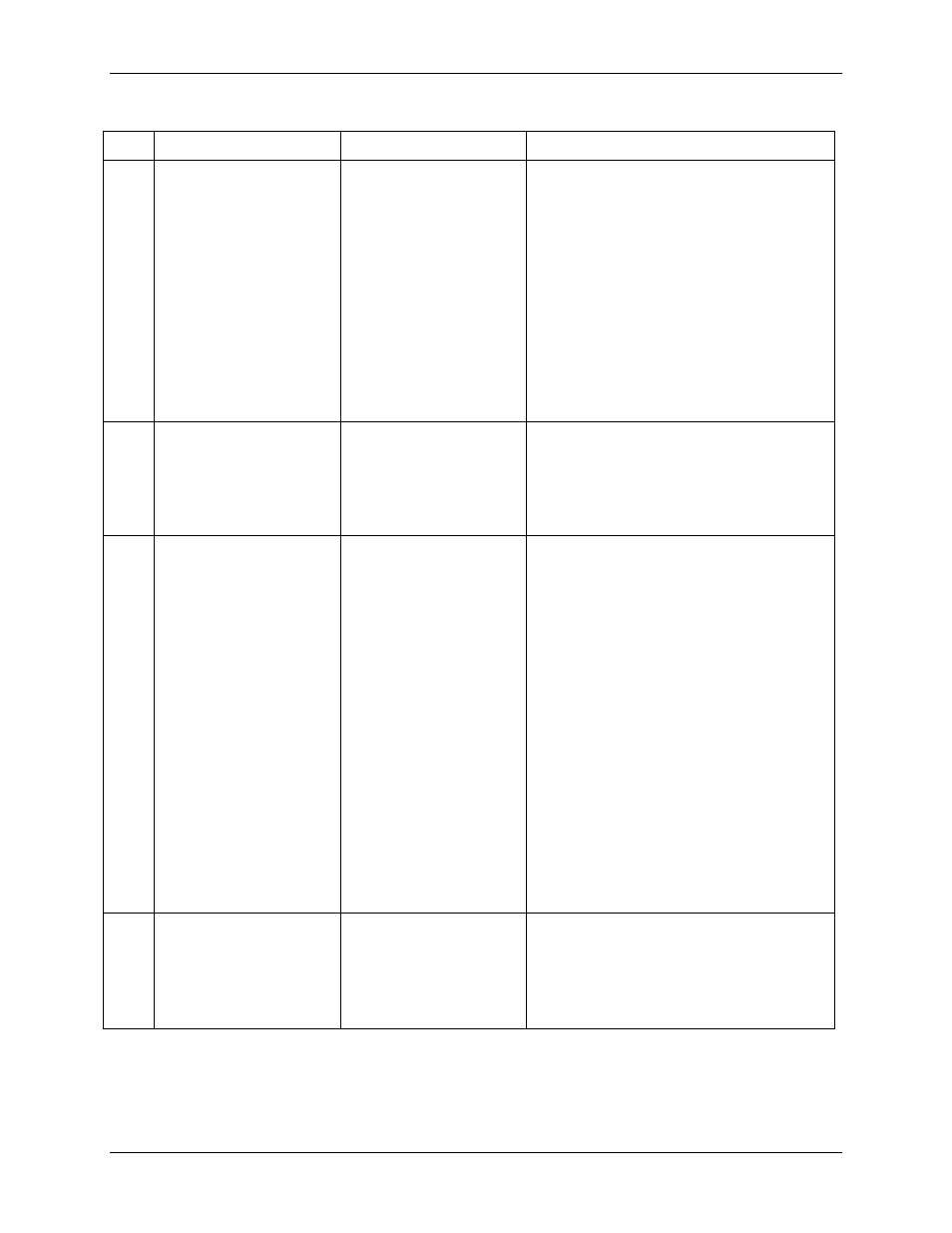

Table 7-2. Troubleshooting – Electronic Control System (ECS)- Continued

NO.

FAULT INDICATION

PROBABLE CAUSE

CORRECTIVE ACTION

T9

Over-Temp. Alarm

condition cannot be

cleared.

Over-Temp Switch

displays erroneous

temperature readings

1.

Shorted Outlet

Temp. Sensor.

2.

Defective Over-

Temp. Switch

3.

A “No-Flow”

condition caused a

gradual buildup of

heat to the water in

vessel.

4.

External

recirculation pump

shut off or failed.

1. Replace Outlet Temp, Sensor.

2. Replace Over-Temp Switch.

3. Open heater outlet to see if fault

clears. If there is no flow through

heater, go to Probable Cause 4.

4. Check pump to ensure it is turned on

and functioning properly. Also, check

for blockage in the incoming flow.

T10

Over-Temp. Alarm

condition occurs when

doing an initial startup.

Starting system after

being shut down without

following proper initial

start-up procedure.

Refer to Section 4 (Operation) for

starting system after being shut down.

See Pre-Operational Checks and Initial

Start-Up on page 4-1 and follow

instructions (OP1–OP10).

T11

Outlet water temp. far

below Setpoint

1. Incorrect Temp

Controller setting

2. Defective Temp.

Controller.

3. Linkage not properly

connected.

4. Defective Actuator.

5. Control Valve shaft

may be binding

1. Refer to Section 3 and check the

current setting of Over-Temp. Switch.

Readjust if necessary.

2. Disconnect cable plug from Valve

Actuator and verify that the Temp.

Controller is generating a control

signal greater than 4 mA. If not

replace Temp. Controller.

3. Check Control Valve Linkage and verify

it is properly connected and the pin in

the Linkage is in the correct position

for the Valve size being used.

4. Replace Valve Actuator.

5. Refer to Table 7-1, Fault T3, Corrective

Action 2c and perform the steps

indicated.

T12

Wide fluctuations in

outlet water temperature

during large flow

changes.

Flow Sensor output

signal too low for flow

changes. Defective or

clogged Flow Sensor.

Under large changes in flow, the Flow

Sensor output should vary from 0 to 5

VDC. Check the signal level at TB-1 lead

113 to ensure it varies with flow changes.

If not, clean or replace Flow Sensor.