Installation, 1 introduction, 2 electronic control valve type cxt-e installation – AERCO Electronic Controls System (ECS) User Manual

Page 15: Introduction, Electronic, Control, Valve, Type, Cxt-e

Electronic Control System (ECS) and Type CXT-E Valve

2. INSTALLATION

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 15 of 82

AC-105

OMM-0003_0D

2. INSTALLATION

2.1 INTRODUCTION

Normally, the Electronic Control System (ECS) is shipped already installed on the Packaged

Water Heater. However, the Control Valve, Type CXT-E is packed separately. For smaller size

Valves (1” to 2”), the packaged Valve is attached to the base of the shipping crate. For larger

size Valves (2 ½” to 4”), the packaged Valve may be shipped separately due to space

limitations within the Heater shipping crate. Therefore, the installation procedures consist

basically of:

• Installing the Electronic Control Valve, Type CXT-E and associated steam or hot (boiler)

water piping and components.

• Connecting external power to the ECS Control Box

• Connecting and checking electrical connections to the CXT-E Actuator and other ECS

components

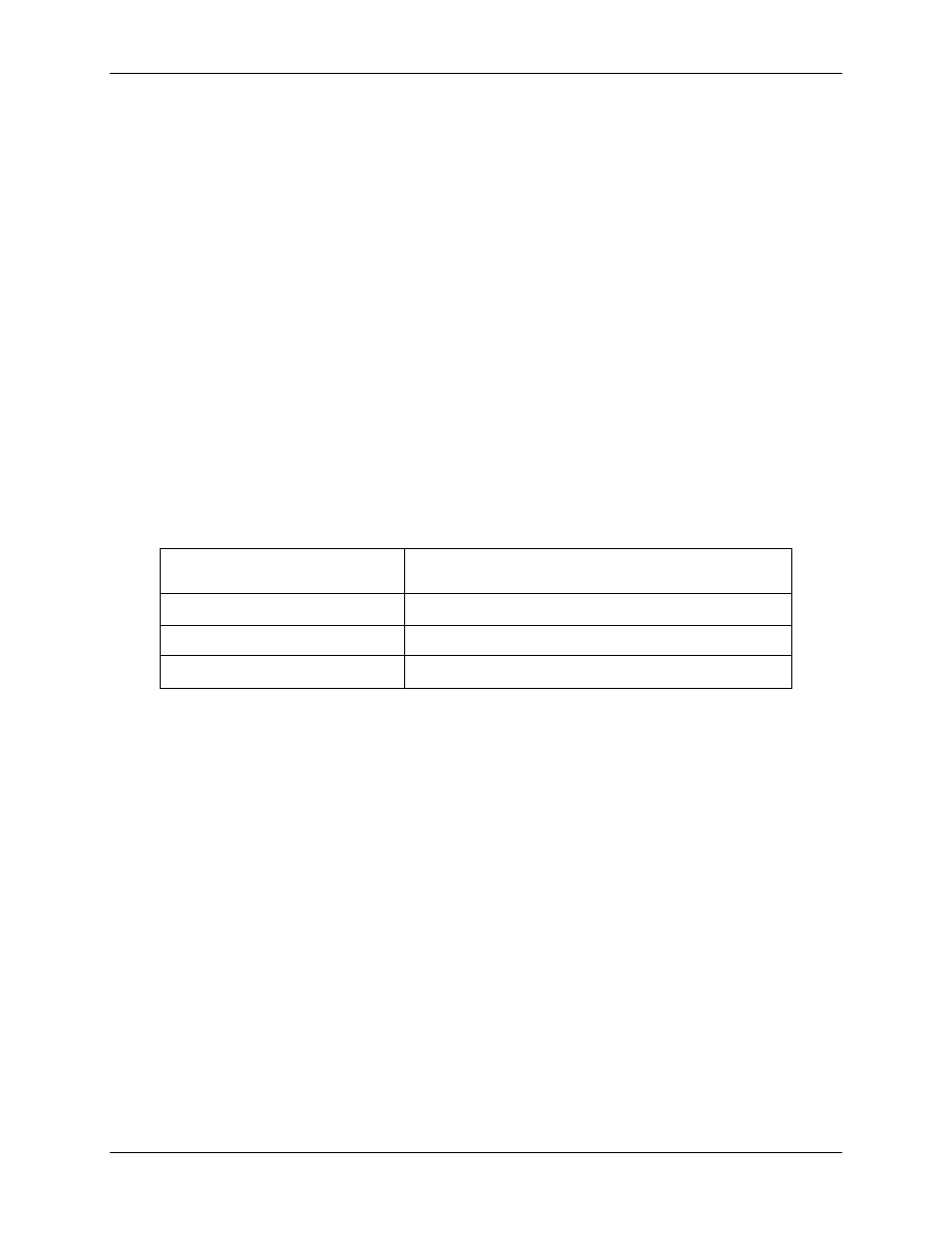

IMPORTANT NOTE!

For Water-to-Water Double-Wall (WWDW) heaters equipped with the

ECS, the following minimum recirculation flow must be provided to

achieve ±4°F temperature control under normal diversified domestic

load conditions:

Double-Wall Model

Minimum System Recirculation

WWDW24

10 gpm

WWDW45

15 gpm

WWDW68

20 gpm

2.2 ELECTRONIC CONTROL VALVE TYPE CXT-E INSTALLATION

The following procedures apply to all sizes of AERCO Electronic Control Valves Type CXT-E

ranging from 1 inch to 4 inches. In addition, the following steps can be used for both steam and

hot (boiler) water flow systems. Proceed as follows:

1) Refer to Figure 1-3 for dimensions of the Control Valve furnished with the Packaged Water

Heater.

2) Next, refer to the recommended installation drawing in Figure 2-1 for steam flow, or Figure

2-2 for hot (boiler) water flow.

3) Install the Control Valve with the Actuator Linkage in the vertical, upright position as shown

in Figure 2-1 or 2-2.

4) For maintenance purposes, unions are required with threaded ends to simplify removal

from the steam or hot boiler water line.

5) Blow out all pipe lines to clear them of dirt chips, scale or other foreign matter which could

adversely affect Valve operation when in service.

6) Install an in-line strainer upstream of the Valve as shown in Figure 2-1 (steam) or Figure 2-

2 (hot boiler water). This will protect against foreign matter reaching the Valve during

service operation.