Cleaning procedure, 2 cleaning procedure – AERCO Electronic Controls System (ECS) User Manual

Page 39

Electronic Control System (ECS) and Type CXT-E Valve

6. ROUTINE MAINTENANCE

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 39 of 82

AC-105

OMM-0003_0D

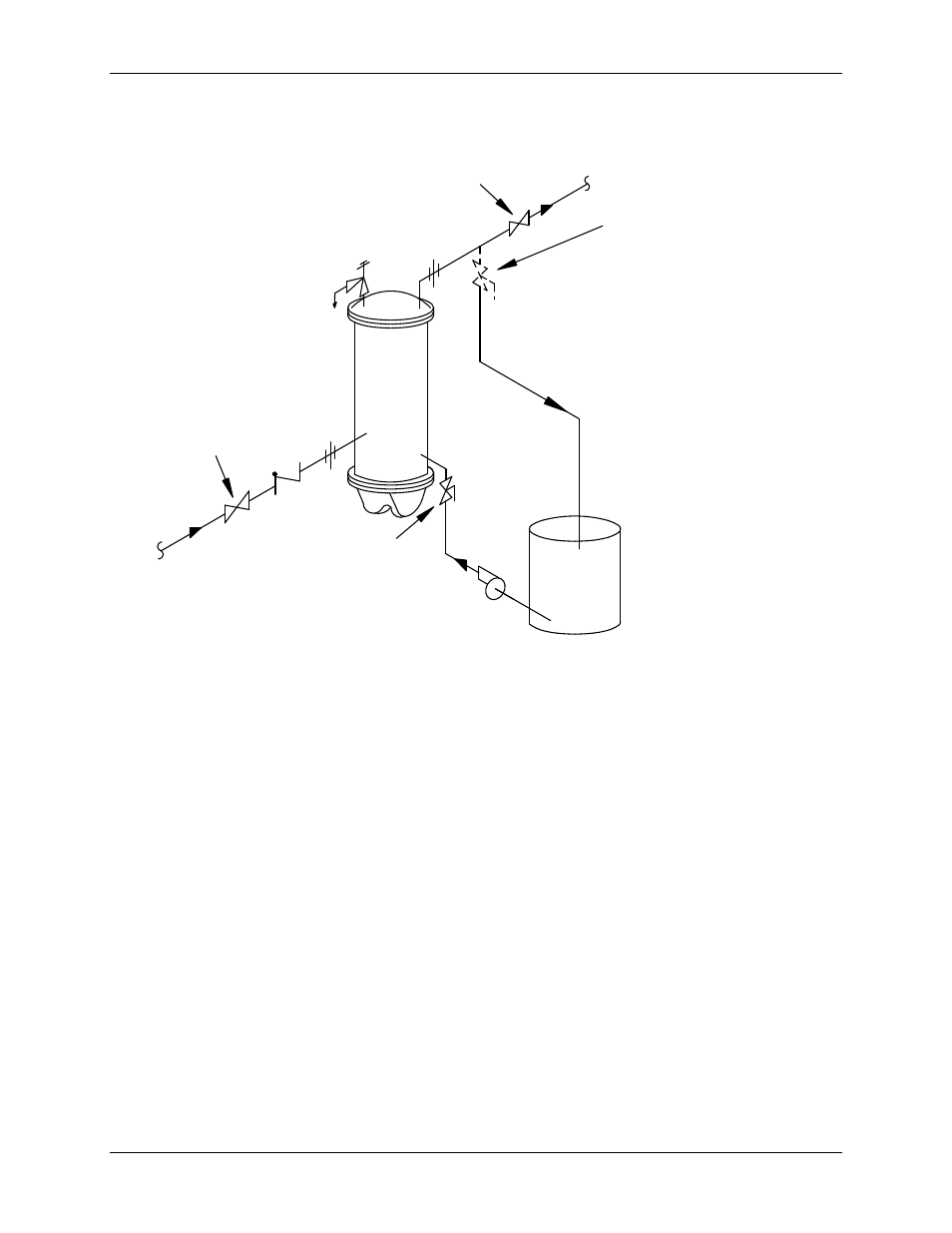

5) Install a valve and hose connection in the outlet piping of the heater (Figure 6-3) and route

the hose back to the top of the circulation bucket.

CIRCULATED HYDROSKRUB SOLUTION

FROM TOP OF HEAT EXCHANGER INTO

BUCKET

NOTE: IF A HOSE CONNECTION IS NOT

AVAILABLE IN THE HOT WATER OUTLET

PIPING, UNUSED PORT AT THE TOP OF

THE HEAT EXCHANGER, IF AVAILABLE,

MAY BE USED.

HYDROSKRUB SOLUTION CIRCULATED

FROM THE BOTTOM OF BUCKET TO THE

DRAIN CONNECTION OF THE HEAT

EXCHANGER.

CLOSE THE

COLD WATER INLET

ISOLATION VALVE

CLOSE THE

HOT WATER OUTLET

ISOLATION VALVE

DRAIN VALVE

HOSE CONNECTION

CIRCULATING

BUCKET

Figure 6-3. Sample HydroSkrub Pumping System Set-Up for Double-Wall Heater

6.4.2 Cleaning Procedure:

1) Slowly add the prescribe amount of the Hydroskrub solution to the circulating bucket.

2) Open the drain and outlet hose connection valves and turn on the pump. Periodically check

for leaks and maintain the liquid level in the bucket. A lowering volume level is an indication

that there is an open drain in the system.

3) Check the cleaning circuit to ensure that the HydroSkrub solution is flowing from the

circulation bucket, through the pump and the heater and back to the top of the top of the

bucket.

4) Return discharge foaming indicates an active HydroSkrub solution and the presence of

mineral deposits in the equipment.

5) Additional HydroSkrub and/or water may be required to maintain circulation and to prevent

the pump from cavitating.

6) Circulate through the Heat Exchanger and piping for 1 to 3 hours. Estimate the circulation

period based on the time in service and water hardness. If the heating equipment is more

than 40 gallons, the circulation time may need to be extended to complete cleaning. When

foaming action stops, HydroSkrub strength is depleted (two pounds of deposits removed per

gallon used) or the equipment is free from calcium and other water-formed mineral deposits.