Appendix c, Calibration check, Appendix c calibration check – Brookfield RST Rheometer User Manual

Page 56

Brookfield Engineering Labs., Inc.

page 56

Manual No. M14-223

Appendix C Calibration Check

The calibration check procedure is performed in order to verify that your RST Rheometer is making correct

viscosity measurements. It can be done in standalone mode or under control of Rheo-3000 software

running on a PC. Perform the calibration check with the spindle that is most frequently used with your

instrument. You do not need to perform a calibration check with additional spindles unless there is a

concern that a specific spindle is not measuring properly.

The calibration check can be performed at regularly scheduled time intervals determined by you (before

each shift, weekly, monthly, etc) or at any time when there is concern that the instrument is not measuring

correctly.

Before performing the calibration check, it is advisable to perform the Zeroing procedure. This feature is

accessed in the Settings menu in standalone mode. At a minimum run both the High Range and Low

Range Zeroing procedures. The time required to do both is slightly more than a half hour.

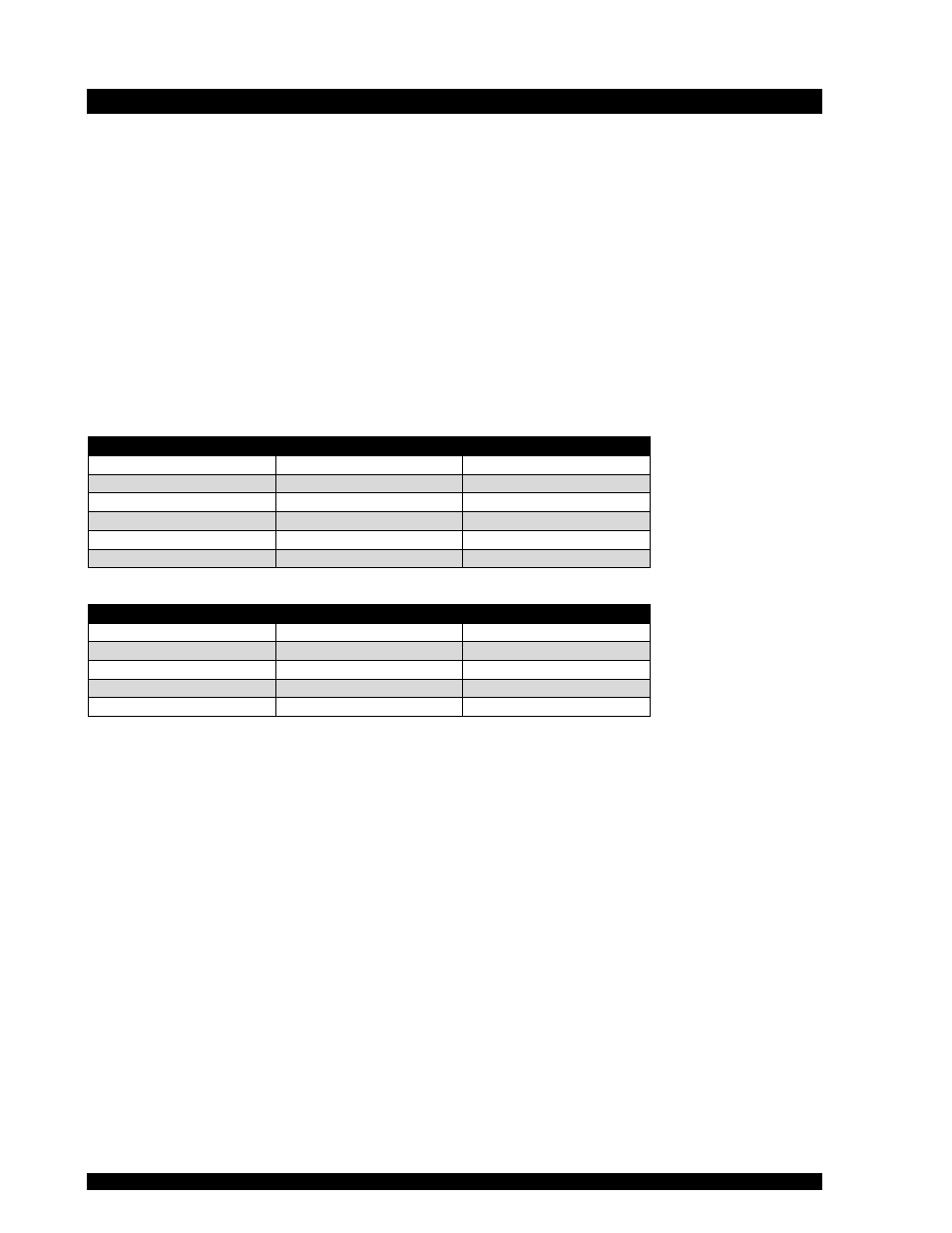

Use the appropriate viscosity standard for the spindle that you want to test. Consult the following table

which shows the fluid that is recommended for each type of spindle and the required sample volume to

perform the calibration check:

Cone Spindles

Fluid

Sample Volume

RCT-25-1

B41000

0.1mL

RCT-25-2

B73000

0.2mL

RCT-50-1

B10200

1.0mL

RCT-50-2

B21000

2.0mL

RCT-75-1

B4900

2.5mL

RCT-75-2

B10200

5.0mL

Coaxial Spindles

Fluid

Sample Volume

CCT-8

B41000

1.0mL

CCT-14

B10200

3.4mL

CCT-25

16.8mL

16.8mL

CCT-40

B2000

68.5mL

CCT-DG

B200

15.7mL

If you have an RST-SST Rheometer and use vane spindles, Brookfield recommends that you perform a

calibration check with any one of the coaxial spindles chamber geometries which will also attach to your

instrument.

Use a circulating temperature bath to condition the viscosity standard to a set temperature, normally 25°C.

All Brookfield viscosity standards are calibrated at 25°C. Additional temperature calibrations are available

upon request when the fluid is ordered from Brookfield or an authorized dealer. Brookfield also supplies a

selection of TC series Temperature Baths for this purpose.

If you have an RST-CPS Rheometer with Peltier Temperature control, you do not require the circulating

temperature bath. Temperature control capability is built into the plate on the instrument.

Prepare the proper sample volume for the test and condition to the defined temperature within +/- 0.1°C.

Mineral oil is highly temperature sensitive, so it is important to do this correctly. If using the RST-CPS

Rheometer, trim the sample around the circumference of the cone spindle.

The calibration check procedure is performed at 3 separate controlled torque values: 125, 250 and 375

per mille. The spindle rotates for at least one minute at each torque value. The viscosity reading at each

torque value is recorded. The three viscosity readings must each be within +/- 3% of the actual fluid value

for the calibration check to pass.