Waterworks Highgate Wall Mounted Exposed Tub Filler with White Porcelain Handshower and Metal Cross Handles User Manual

Installation guidelines

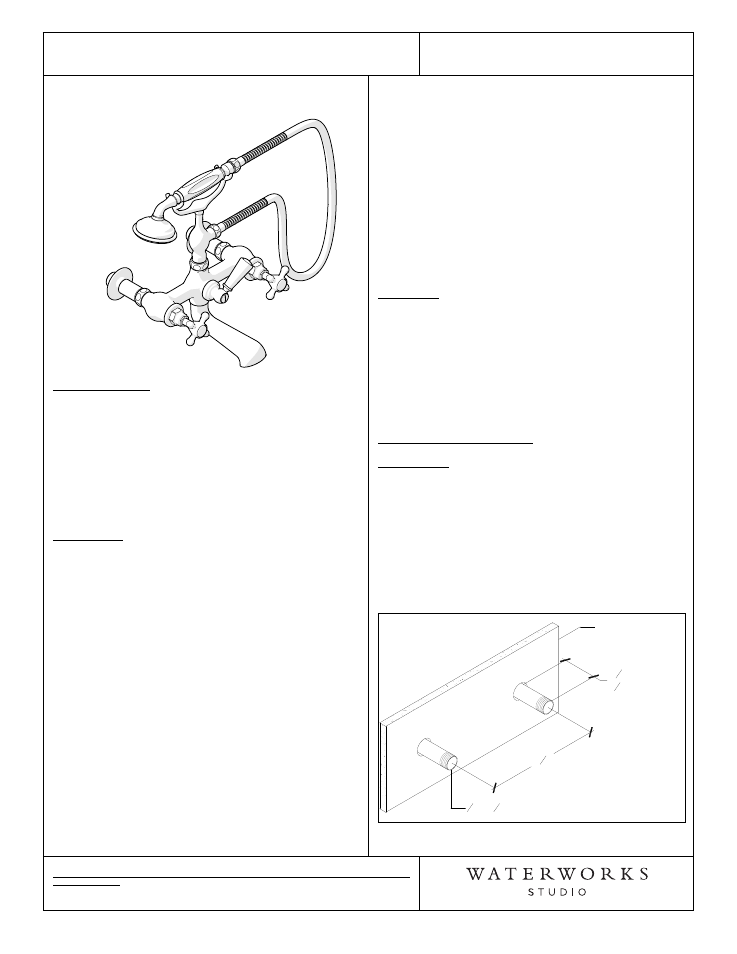

HIGHGATE

Exposed Wall Mounted Tub Filler With Handshower

INSTALLATION GUIDELINES

Page 1 of 3

6.11.2012

These guidelines have been prepared for the professional contractor to aid in the installation of:

HIGHGATE WALL MOUNTED TUB FILLER WITH HANDSHOWER & METAL CROSS HANDLES

(STYLE# HGXT20)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

Metal Cross Handles

Style No. HGXT20

SPECIFICATIONS:

Handle Spread: 7-5/8" (NOT ADJUSTABLE)

Inlet Connection Size: 3/4"

Inlet Connection Type: Male NPT

Inlet Connection Spread 7-5/8" (NOT ADJUSTABLE)

Maximum Water Pressure: 80psi

Minimum Water Pressure: 20psi

Fittings Hole Diameter: 1-1/4"

Recommended Water Pressure: 45psi

Spout Reach: 8-7/8"

IMPORTANT:

¾

To ensure this product is installed properly, you

must read and follow these guidelines.

¾

The owner/user of this product must keep this

information for future reference.

¾

Be sure your installation conforms to federal state,

and local codes. Anti-scald protection is the

responsibility of the installer and according to

applicable codes.

¾

In the State of Massachusetts, all installations must

comply with the rules and regulations set forth

within 248 CMR.

¾

This product must be installed by a professional

licensed contractor.

¾

Product should be on-site prior to rough-in. This

allows the installer to visualize the installation and

verify the inlet connection spread.

¾

Refer to the specifications and assembly drawings

attached. Product is sold partially assembled but

shown fully disassembled for illustrative and service

purposes only.

¾

Check tub measurements to assure the spout

projects far enough into the tub.

¾

Inspect this product to ensure you have all the parts

required for proper installation.

¾

Use only a strap wrench or protected/smooth-jaw

wrench on any finished surface.

¾

Run 3/4" supply lines for maximum flow.

¾

Install accessible hot and cold service stop valves to

facilitate servicing.

ROUGH-IN:

1.

Run well supported 3/4" hot and cold supply lines

for maximum water flow.

2. Install 3/4" Female NPT adapters (NOT SUPPLIED).

Ensure that the adapters are secure, level, at the

proper spread of 7-5/8" (NOT ADJUSTABLE) and at

equal depths. The final distance the nipples (1) must

project from the surface of the finished wall must be

between 1-1/8" and 2-1/4". See Figure-01.

TUB FILLER INSTALLATION:

IMPORTANT:

¾

Verify the 7-5/8" inlet supply spread prior to

installation.

3. Thread the 3/4" NPT end of the nipples (1) to the

3/4" Female NPT adapters (NOT SUPPLIED).

4. Slide the escutcheons (3) over the nipples and up to

the finished wall. Make sure the washer (2) is behind

each escutcheon.

Figure - 01

7

5

8

"

3

4

" x

3

4

" NPT Nipple

Finished Wall

1

1

8

" MIN

2

1

4

" MAX

PROJECTION FROM

FINISHED WALL