Installation guidelines, Ludlow – Waterworks Ludlow Thermostatic Control Valve Trim with Metal Lever Handle User Manual

Page 2

PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

LUDLOW

Thermostatic Control Valve Trim

INSTALLATION GUIDELINES

Page 2 of 2

10.30.2013

These guidelines have been prepared for the professional contractor to aid in the installation of:

LUDLOW THERMOSTATIC CONTROL VALVE TRIM WITH METAL CROSS HANDLE (STYLE#

LDTH01) & METAL LEVER HANDLE (STYLE # LDTH10)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

SEE SERVICE PART DOCUMENT FOR PART ORDERING, AVAILABLE ON WATERWORKS.COM

INSPECT THE CALIBRATION:

6. Turn the cartridge stem clockwise then turn the

water on and confirm the limit stop is functioning

properly by turning the stem counter-clockwise until

the limit stop prevents further rotation.

7. Verify the temperature to be the max temperature

set in Step 4. If it is not the correct temperature,

repeat the calibration process.

TRIM PLATE INSTALLATION:

8. Re-install the THREADED TUBE and make a mark on

the tube that is 1/8" in front of the finished wall.

9. Remove the tube then cut the tube at the mark

made in Step 8. DO NOT cut the end of the tube

with the internal threads. See Figure 3.

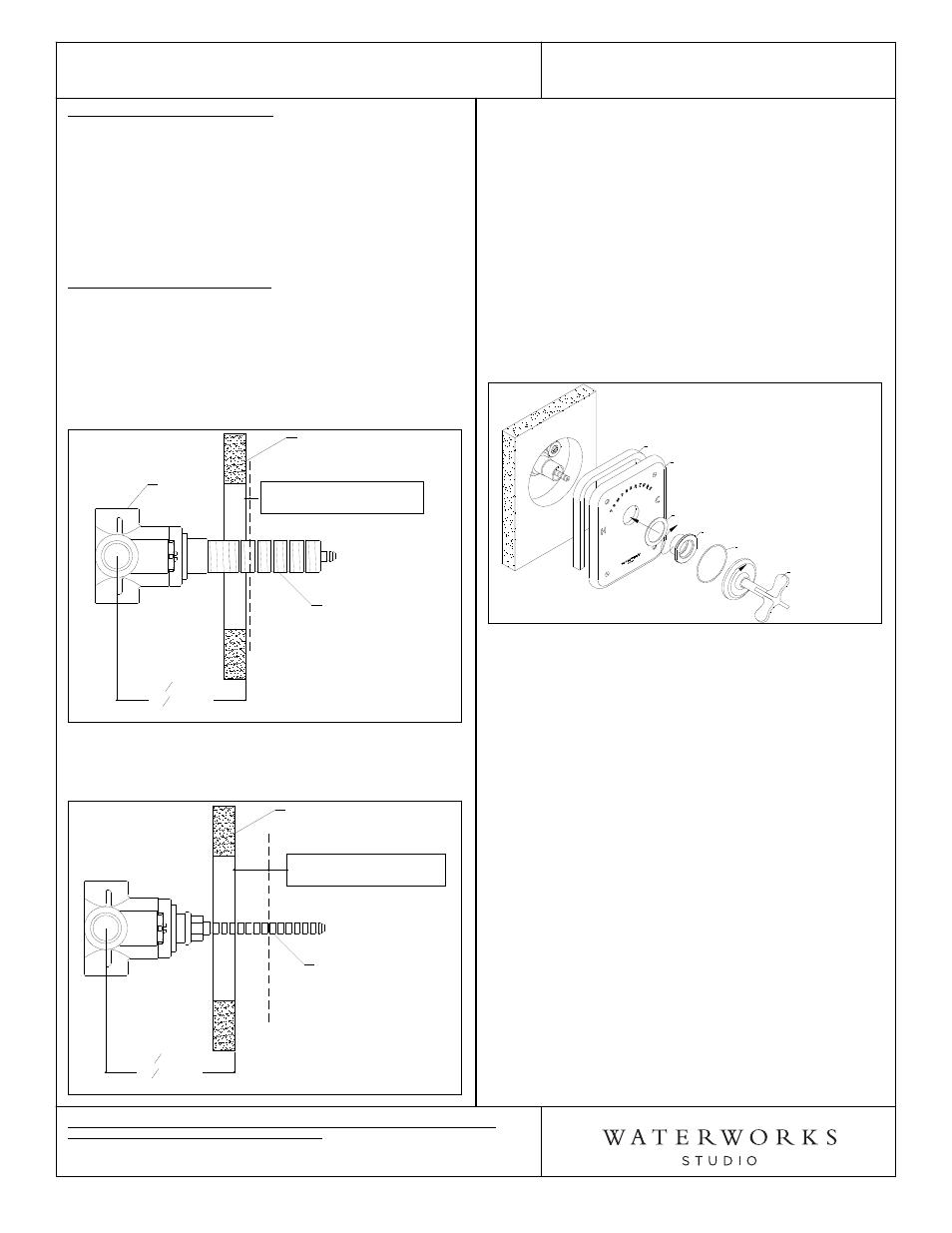

Figure 3

THREADED TUBE

FINISHED WALL

3

1

4

"MIN

4

1

4

"MAX

ROUGH IN

CUT TUBE 1/8" IN FRONT

OF THE FINISHED WALL

VALVE

10. Mark and then cut the CARTRIDGE STEM 1" in front

of the finished wall. See Figure 4.

Figure 4

CARTRIDGE STEM

FINISHED WALL

3

1

4

"MIN

4

1

4

"MAX

ROUGH IN

CUT STEM 1" IN FRONT

OF THE FINISHED WALL

¾ See Figure 5. for Steps 11-13.

11. Re-install the cut THREADED TUBE onto the VALVE.

12. Hold the TRIM PLATE against the finished wall,

making sure FOAM GASKET is touching the wall.

Thread and tighten the TRIM CONNECTOR onto the

threaded tube, making sure the RED FIBER

WASHER is between the trim connector and trim

plate.

13. With the correct orientation, thread the HANDLE

ASSEMBLY onto the TRIM CONNECTOR making

sure the O-RING is between the escutcheon and

TRIM PLATE. Note: The escutcheon is used to

tighten handle assembly.

Figure 5

FOAM GASKET

TRIM PLATE

RED FIBER WASHER

TRIM ADAPTER

O-RING

HANDLE

ASSEMBLY

¾ NOTE: The screws on the front of the trim plate are

aesthetic only and do not serve any mechanical

purpose and should not be removed.

¾ If further assistance is required, please contact

Product Support at 1-800-927-2120 (8am-6pm EST).

¾ See service part document for parts ordering,

available on WATERWORKS.COM.