Waterworks Ludlow Thermostatic Control Valve Trim with Metal Lever Handle User Manual

Installation guidelines

PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

LUDLOW

Thermostatic Control Valve Trim

INSTALLATION GUIDELINES

Page 1 of 2

10.30.2013

These guidelines have been prepared for the professional contractor to aid in the installation of:

LUDLOW THERMOSTATIC CONTROL VALVE TRIM WITH METAL CROSS HANDLE (STYLE#

LDTH01) & METAL LEVER HANDLE (STYLE # LDTH10)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

SEE SERVICE PART DOCUMENT FOR PART ORDERING, AVAILABLE ON WATERWORKS.COM

Metal Cross Handle

Style No. LDTH01

Metal Lever Handle

Style No. LDTH10

SPECIFICATIONS:

Control Valve Rough-in Depth Minimum: 3-1/4"

Control Valve Rough-in Depth Maximum: 4-1/4"

Hot Limit Safety Stop: On Thermostatic Valve

REQUIRED PLUMBING DETAILS:

Universal 1/2" Thermostatic Valve

STYLE # GUTH56

IMPORTANT:

¾ NOTE: The screws on the front of the trim plate are

aesthetic only and do not serve any mechanical

purpose and should not be removed.

¾ To ensure this product is installed properly, you

must read and follow these guidelines.

¾ The owner/user of this product must keep this

information for future reference.

¾ This product is intended to work with the

Waterworks Universal 1/2" Thermostatic Valve

(GUTH56R) which features anti-scald protection.

The risk of scalding exists until the installer has

properly calibrated/adjusted the temperature

setting and set the integrated high limit stop on the

valve prior to final trim installation.

¾ Be sure your installation conforms to federal state,

and local codes. In the State of Massachusetts, all

installations must comply with the rules and

regulations set forth within 248 CMR.

¾ This thermostatic valve trim only mixes hot and cold

water. It does not have volume control or shut-off

capabilities. A diverter or wall valve (sold

separately) control on/off/volume and must be

installed for each fitting that will have water flowing

to it. This valve trim cannot be used directly with a

diverting tub spout.

¾ This product must be installed by a professional

licensed contractor and must be onsite prior to

rough-in, this allows the installer to visualize the

installation.

¾ Inspect this product to ensure you have all the parts

required for proper installation.

¾ Use only a strap wrench or protected/smooth-jaw

wrench on any finished surface.

¾ The use of certain plumber's putty may stain stone

or tile surfaces.

TEMPERATURE CALIBRATION:

¾ The risk of scalding exists until the installer has

properly calibrated/adjusted the temperature

setting prior to final trim installation.

1.

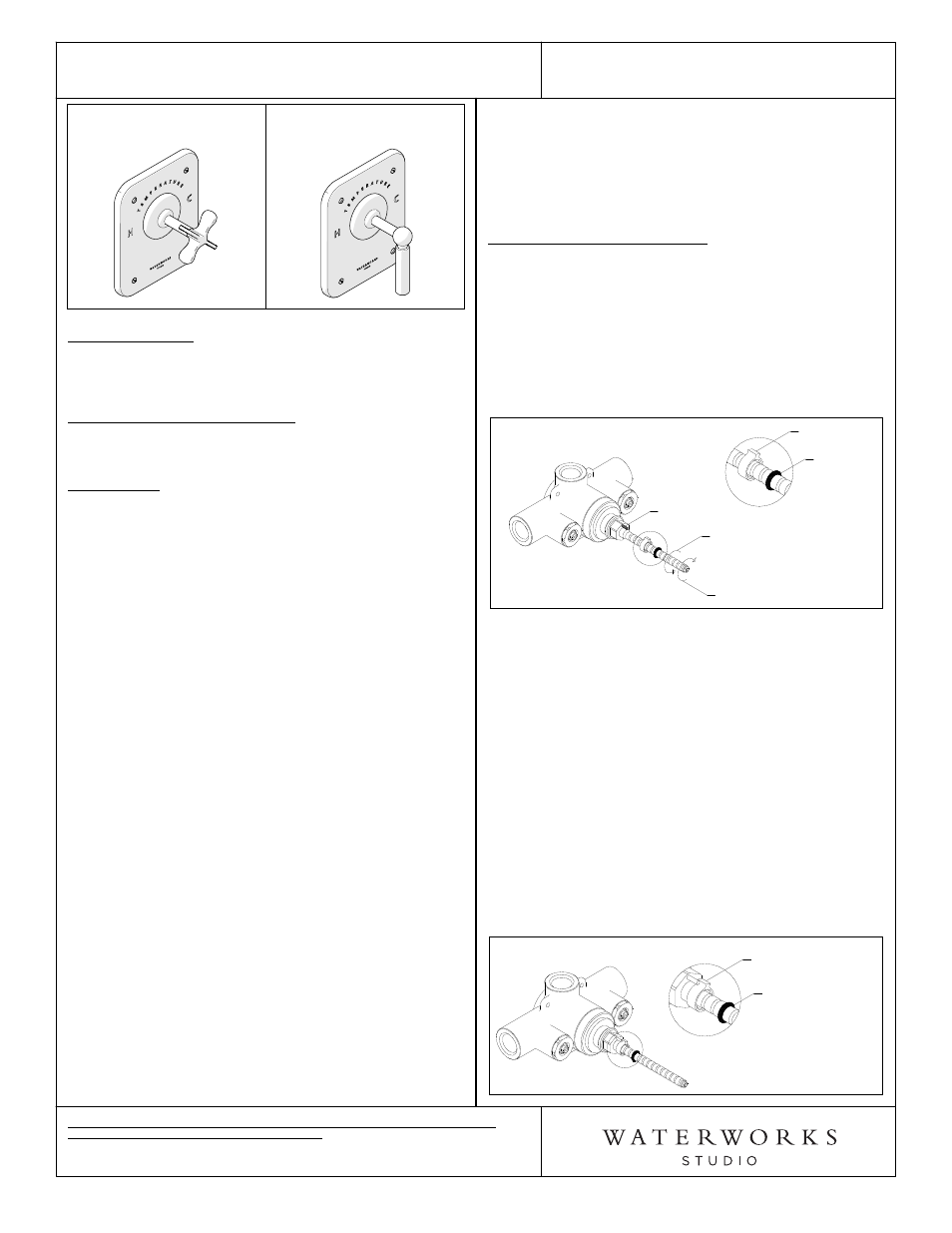

Remove the tile guard and threaded tube. Slide the

o-ring and limit stop up on the cartridge stem. DO

NOT REMOVE OR DAMAGE THE O-RING. See

Figure 1.

Figure 1

Limit Stop

O-Ring

Limit Stop Pin

Clockwise - Cold

Counter Clockwise - Hot

2. Turn on the water supply and a wall valve to run

water through the thermostatic valve.

3. Slowly rotate the cartridge stem clockwise to attain

full cold then rotate it counter-clockwise to attain

full hot. Verify a full range of temperature exists.

NOTE: It is approximately 3/4 of a rotation from full

cold to full hot.

4. With the water running, rotate the cartridge stem to

the adjust the temperature to the maximum desired

bathing temperature, verified with a thermometer.

5. Slide the limit stop back onto the cartridge stem,

making sure to properly align it with the pin on the

cartridge bonnet. Slide the o-ring back to its original

position to prevent the limit stop from sliding off the

stem then turn the water off. See Figure 2

Figure 2

Align limit stop to

the pin.

Slide o-ring down

to hold limit stop.