Installation guidelines – Waterworks Henry Thermostatic with Shutoff Trim User Manual

Page 2

PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

HENRY

Thermostatic with Shutoff Trims

INSTALLATION GUIDELINES

Page 2 of 3

11.14.2012

These guidelines have been prepared for the professional contractor to aid in the installation of:

HENRY METAL LEVER HANDLE WITH THERMOSTATIC WITH METAL CROSS HANDLE SHUTOFF

TRIMS (STYLE# HNTH30)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

SEE SERVICE PART DOCUMENT FOR PART ORDERING, AVAILABLE ON WATERWORKS.COM

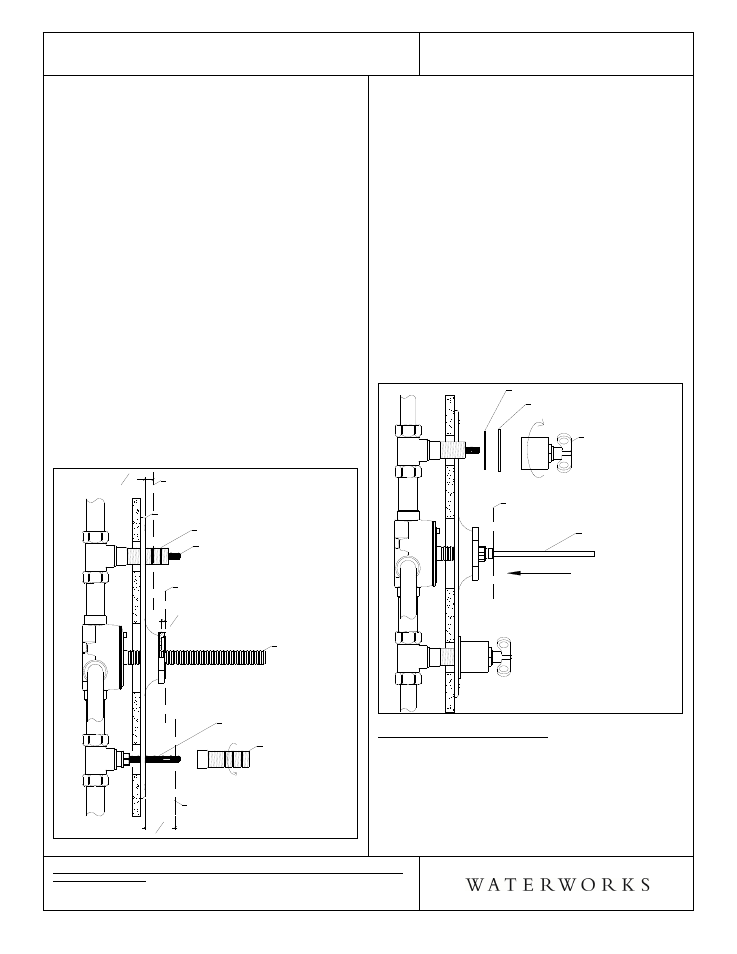

3. Hold the back plate up to the finished wall and slide

the thermo trim plate over the all thread tube. Make

sure the thermo trim plate is centered on the back

plate and the threaded sleeves on the shut-off

valves pass through the holes on the back plate.

¾

See Figure - 02 for steps 4 - 8

4. While holding the back plate and thermo trim plate

against the finished wall, mark the all thread tube at

a point 3/16" beyond where it protrudes from the

trim plate. Make a mark on the threaded sleeves that

is 1/2" from the front face of the back plate.

5. Remove the threaded sleeves from the shut-off

valves and make marks on the splined stems that are

1-3/8" from the front face of the back plate.

6. Remove the trim plate, the back plate, the all thread

tube and the threaded sleeves from the valve. Cut

the all thread tube and threaded sleeves at the

marks made in Step 4. DO NOT cut the ends that

have the internal threads.

7. Cut the splined stems at the marks made in Step 5.

8. Re-attach the all thread tube and threaded sleeves

then hold the back plate against the finished wall

and slide the trim plate is centered and fits properly

into the opening in the back plate.

Figure - 02

Cut Plane

For All Thread Tube

1 3 8"

Cut Plane

For Splined Stem

Threaded

Sleeve

Spline Stem

Spline Stem

Threaded Sleeve

Face of Back Plate

Cut Plane

For Threaded Sleeve

All Thread

Tube

3

16"

1

2"

¾

See Figure - 03 for steps 9 - 12

9. Tightly thread the trim nut onto the all thread tube.

This will hold the trim plate to the back plate against

the wall.

10. Slide the escutcheons, with rubber washers behind

them, over the 2 cut threaded sleeves. Tighten the

shut-off handle assemblies on the threaded sleeves,

making sure the escutcheon is centered and the

handle is in the correct orientation.

11. Fully insert the square tube into the trim nut, then

by feel, make sure it slides over the stem and stops

against the valve cover plate. When seated properly

onto the stem, the square tube will have rotational

resistance.

12. Mark the square tube at the point where it passes

through the face of the trim nut. Remove the square

tube and cut it 1/8" behind the mark that was just

made. Re-insert the tube back into the trim nut

making sure it is slightly recessed into the nut.

Figure - 03

Mark Plane

For Square Tube

Square Tube

Shut off

Handle Assembly

Escutcheon

Rubber Washer

TEMPERATURE CALIBRATION:

¾

See Figure - 04 for Steps 13 - 17

¾

The risk of scalding exists until the installer has

properly calibrated the temperature setting.

13. Turn on the water supply and one of the shut-off

valves to run water through the valve and insert a

bladed screw driver into the square tube.