Waterworks Henry Thermostatic with Shutoff Trim User Manual

Installation guidelines

PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

HENRY

Thermostatic with Shutoff Trims

INSTALLATION GUIDELINES

Page 1 of 3

11.14.2012

These guidelines have been prepared for the professional contractor to aid in the installation of:

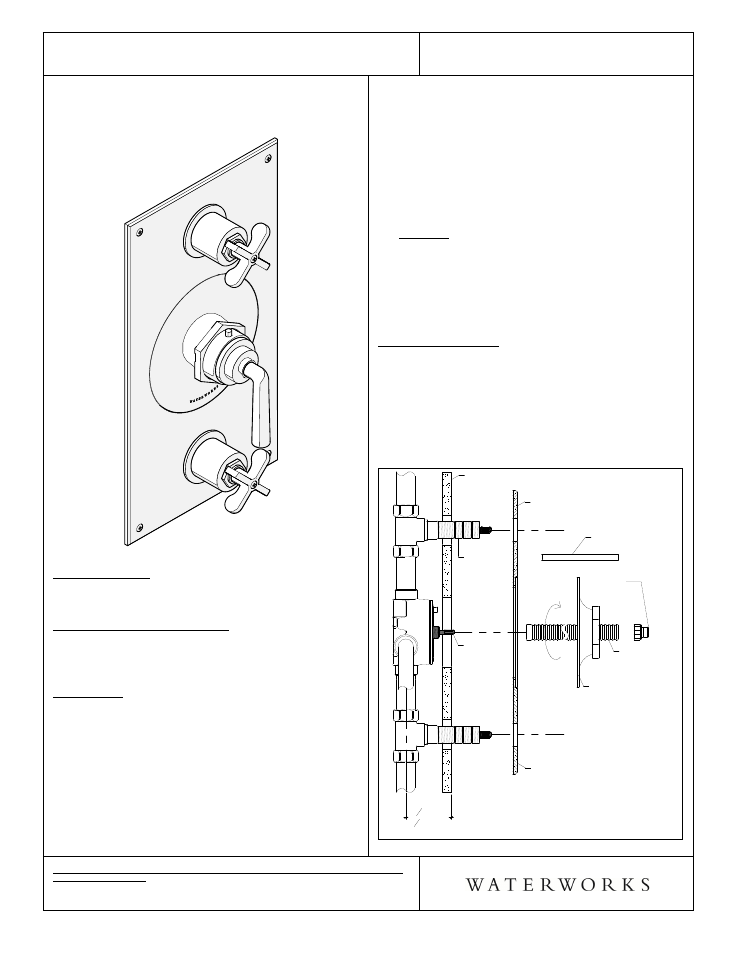

HENRY METAL LEVER HANDLE WITH THERMOSTATIC WITH METAL CROSS HANDLE SHUTOFF

TRIMS (STYLE# HNTH30)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

SEE SERVICE PART DOCUMENT FOR PART ORDERING, AVAILABLE ON WATERWORKS.COM

Metal Lever Handle Thermostatic with Metal Cross

Handle Shutoff Trims

Style No. HNTH30

Code No. HNSV30

SPECIFICATIONS:

Control Valve Rough-In Depth: 2-1/8" MIN - 3-1/8" MAX

Hot Limit Safety Stop: Yes

REQUIRED PLUMBING DETAILS:

Henry Thermostatic Valve

STYLE No. GUTH47

CODE No. GUSV47R

IMPORTANT:

¾

To ensure this product is installed properly, you

must read and follow these guidelines.

¾

The owner/user of this product must keep this

information for future reference.

¾

This product is intended to work with the Henry

Thermostatic Valve which features anti-scald

protection. The risk of scalding exists until the

installer has properly calibrated/adjusted the

temperature setting during final trim installation.

¾

Be sure your installation conforms to federal state,

and local codes. In the State of Massachusetts, all

installations must comply with the rules and

regulations set forth within 248 CMR.

¾

This product must be installed by a professional

licensed contractor and must be onsite prior to

rough-in, this allows the installer to visualize the

installation.

¾

This product and the required valve (GUTH47)

CANNOT be installed horizontally. This product

must be installed with all the handles aligned

vertically as shown in the image to the left.

¾

Use only a strap wrench or protected/smooth-jaw

wrench on any finished surface.

¾

DO NOT use putty on fittings.

TRIM INSTALLATION :

¾

See Figure - 01 for steps 1 & 2

1.

Remove the tile guards from the valve.

2. Unthread the trim nut adapter from the all thread

tube, remove the square tube, then thread the all

thread tube onto the cartridge stem.

Figure - 01

2

1

8

"MIN

3

1

8

"MAX

ROUGH-IN

Screws on back plate

are aesthetic only

Cartridge

Stem

Threaded

Sleeve

Back Plate

Finished Wall

All Thread

Tube

Square Tube

Trim Nut

Adapter

Thermo Trim

Plate