Waterworks Easton Classic Pressure Balance with Diverter Trim with Oak Lever Handles User Manual

Installation guidelines

Easton

®

Pressure Balance With Diver ter

3/05

W A T E R W O R K S

®

These guidelines have been prepared for the professional contractor to aid in the installation of:

PRESSURE BALANCE WITH DIVERTER (

EASV92-K & GUSV86R

) (

EASV93-K &

GUSV86R

) (

EASV94-K & GUSV86R

) (

EASV95-K & GUSV86R

)

All dimensions are based on original specifications and are subject to change and variation.

Please consult your Design Associate for current specifications.

Installation Guidelines

1

➢ Refer to the specification and assembly drawings attached.

Valves are sold partially assembled but shown fully

disassembled for illustrative and service purposes only.

➢ f soldering any connections, remove cartridge to prevent

damage to seals.

➢ This valve should be on-site prior to rough in and allows the

installer to visualize the installation.

➢ Inspect this product to assure you have all parts required for

proper installation.

➢ Check incoming water pressure; ideal operating pressure is

40-50 psi.The minimum is 25 psi. and the maximum is 80 psi.

➢ Use only a strap wrench or protected/smooth-jaw wrench on

any finished surface.

ROUGH IN:

1. Make sure the valve body is positioned according to valve

markings so the inlets are situated with hot piped on the left

and cold piped on the right.

2. Remove and discard the wall mounting flange(T-177) located

beneath the tile shield.The dome cover(T-19) included will

not be used during the installation.

3. REQUIRED: Valve body rough-in depth is 2 3/8" +/- ½" from

the centerline of the supplies/inlets to the face of the finished

wall. Install so the back side of the plaster shield contacts the

finished wall as indicated on the shield.

4. Run 1/2" copper supply lines with a 5 ½" center spread to

the proper height of the valve inlets and be sure to secure all

piping and fittings.

5. Turn on the hot and cold supplies then check for leaks.

VALVE OPERATION:

6. When the finished wall is complete, turn on the hot and cold

supplies and pull off the tile shield(T-176) and discard. Both

supplies must be on or the valve will not operate.

7. The larger of the 2 handles is for controlling temperature

only, not volume. The smaller handle is used to divert the

water flow to another fitting. Install the large handle so it

rests at 6 o-clock in the OFF position then turn the handle

counter clockwise through the cold position then warm and

stopping at the hot position. If additional rotational friction is

required to maintain the handle position, tighten the packing

nut(T-17).

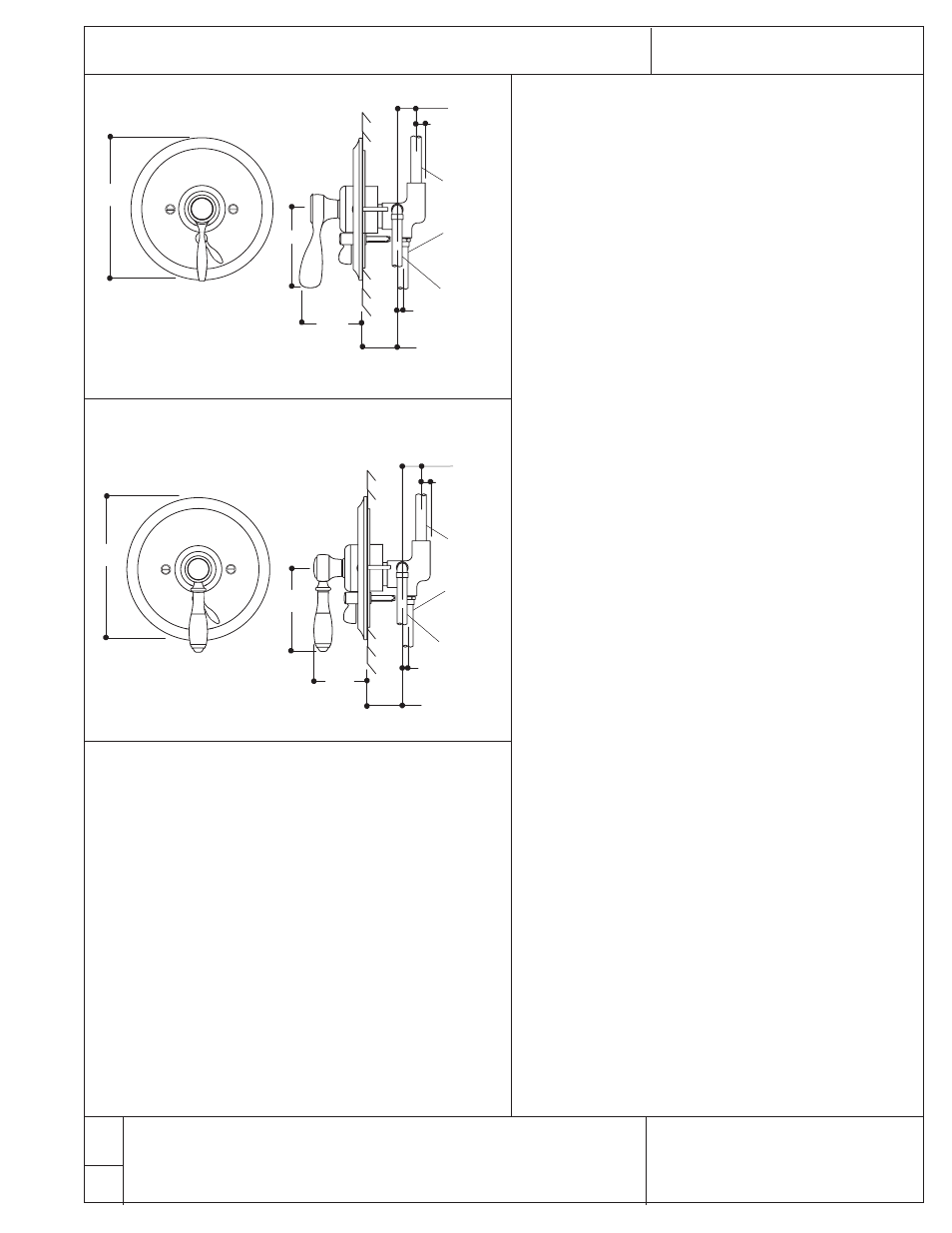

EASV92-K (metal lever handle trim) & GUSV86R (rough)

5

/

8

"

shower

discharge

inlet

tub

discharge

1

/

2

"

2

3

/

8

" ±

1

/

2

"

Ø5

7

/

8

"

2

1

/

2

"

1

/

2

"

w a t e r w o r k

s

C

H

3"

5

/

8

"

shower

discharge

inlet

tub

discharge

1

/

2

"

2

3

/

8

" ±

1

/

2

"

2

1

/

8

"

1

/

2

"

Ø5

7

/

8

"

C

H

w a t e r w o r k

s

3

3

/

8

"

EASV93-K (white porcelain lever handle trim) & GUSV86R (rough)

EASV94-K (black porcelain lever handle trim) & GUSV86R (rough)

EASV95-K (oak lever handle trim) & GUSV86R (rough)

IMPORTANT

➢

➢ T

To

o e

en

nssu

urre

e tth

hiiss p

prro

od

du

ucctt iiss iin

nssttaalllle

ed

d p

prro

op

pe

errllyy,, yyo

ou

u m

mu

usstt rre

eaad

d

aan

nd

d ffo

ollllo

ow

w tth

he

esse

e ggu

uiid

de

elliin

ne

ess..

➢

➢ T

Th

he

e o

ow

wn

ne

err//u

usse

err o

off tth

he

e vvaallvve

e m

mu

usstt kke

ee

ep

p tth

hiiss iin

nffo

orrm

maattiio

on

n ffo

orr

ffu

uttu

urre

e rre

effe

erre

en

ncce

e..

➢ The risk of scalding exists until the installer has properly set

the temperature high limit stop.

➢ This product must be installed by a professional contractor

and conform to all applicable codes