Motor, Trouble probable cause remedy – Craftsman 113.299210 User Manual

Page 46

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

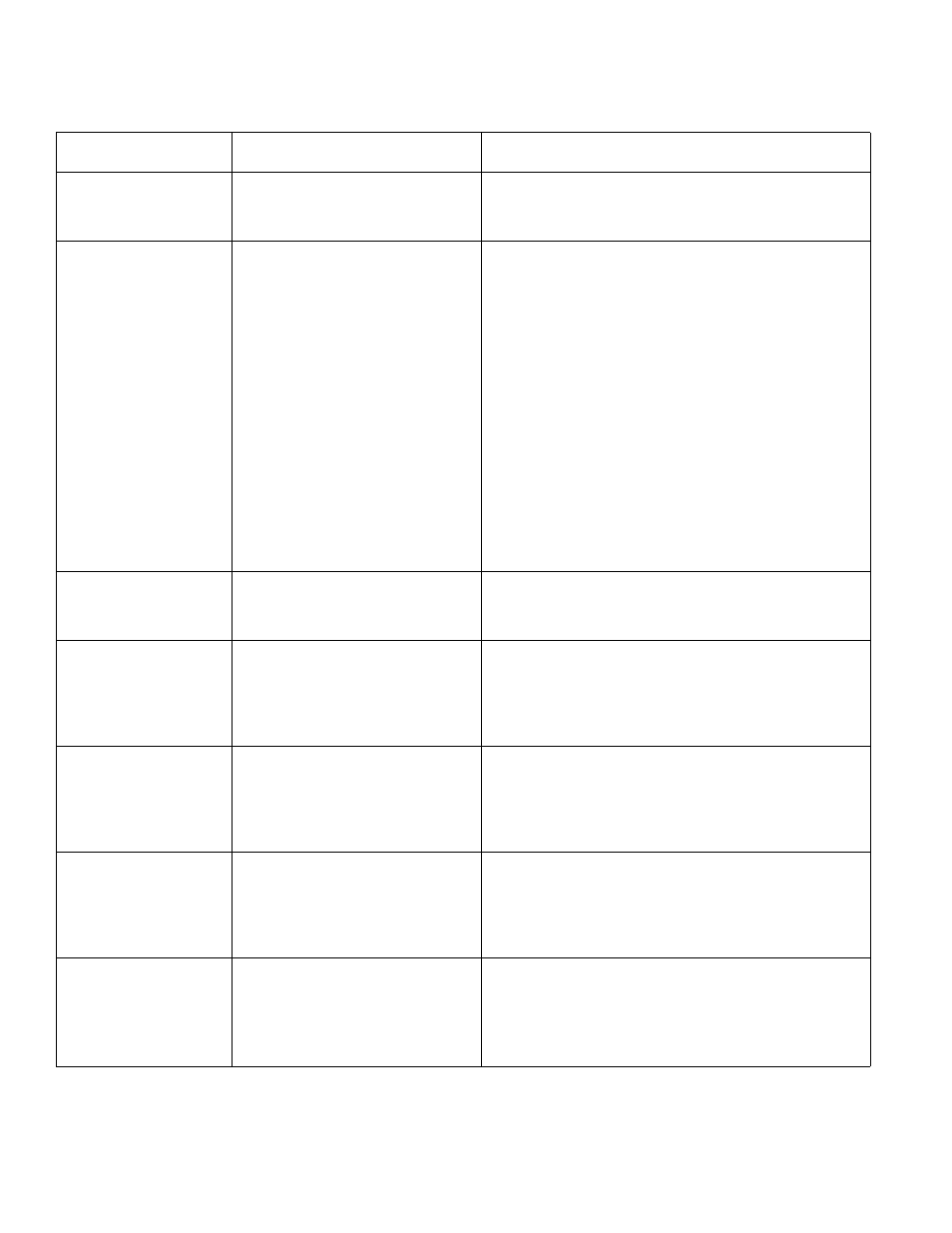

Motor

N O TE: M otors used on wood w orking tools are particularly susceptible to the accum uiation of saw dust and wood chips

and should be blow n out or “Vacuum ed" frequenfiy to prevent interference w ith norm al m otor ventilation

Trouble

Probable Cause

Remedy

Excessive N oise

1, M otor

1 H ave m otor checked by qualified service technician

R epair service is available at your nearest S ears

store.

M otor fails to develop

full power

NOTE:

Low

Voltage;

(Power output of m otor

decreases

rapidly

with

decrease in voltage at

m otor term inals For

rpdnrtinn of

10% in voltage causes

a reduction of 19% in

m axim um pow er output

of w hich the m otor is

capable, and a reduc

tion of 20% in voltage

causes a reduction of

36% in m axim um power

output

)

1- C ircuit overloaded w ith lights,

appliances and other m otors

2 U ndersize wires or circuit too

long

3 G eneral overloading of pow er

com pany facilities, (In som e

sections of the country,

dem and for electrical pow er

m ay exceed the capacity of

existing generating and distribu

tion system s

)

4 incorrect fuses of circuit break

ers in pow er line

1

D o not use other appliances or m otors on sam e cir

cuit w hen using the saw

2

Increase w ire sizes, or reduce length of w iring. S ee

“M otor

Specifications

and

electrical

R equirem ents"

section

3 R equest a voltage check from the pow er com pany

4. Install correct fuses or circuit breakers

M otor starts slow ly or

fails to com e up to full

speed

1.

Low voltage-

2 W indings burned out or open

3 Starting relay not operating

1. R equest voltage check from the pow er com pany

2 H ave m otor repaired or replaced.

3. H ave relay replaced

M otor overheats

1 M otor overloaded

2 im proper cooling (Air circuiation

restricted through m otor due to

sawdust, accum ulating inside

of saw

)

1 Feed work slow er into blade

2

C lean out sawdust to provide norm al air circulation

through

m otor

See

“M aintenance"

and

"Lubrication"

section -

R elay w ill not operate

1. Burned contacts {due to

extended hold-in periods

caused by low line voltage, etc.)

2 Saw not in upright position

3. Loose or broken connectors.

1 H ave relay replaced and request a voltage check

from the pow er com pany,

2. Place saw in upright position.

3 H ave w iring checked and repaired.

M otor stalls (rssufting in

biow n fuses or tripped

circuit breakers)

1, Starting relay not operating,

2 Voltage too low to perm it m otor

to reach operating speed

3 Fuses or circuit breakers do not

have sufficient capacity

1 H ave relay replaced

2, R equest voltage check from the pow er com pany

3, Install proper size fuses or circuit breakers,

Frequent opening of

fuses or circuit breakers

1. M otos overloaded

2 Fuses or circuit breakers do not

have sufficient capacity

3, Starting relay not operating

(m otor does not reach speed.)

1

Feed work slow er into blade

2

Install proper size fuses or circuit breakers

3 H ave relay replaced.

46