Work feed devices, Push stick, Push block – Craftsman 113.299210 User Manual

Page 26: W ork feed devices

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Work Feed Devices---------------

Before cutting any wood on your saw, study all of the

“Basic Saw Operations”

As you learn new table saw woodworking techniques,

you'll see that many types of cuts need different support

and feeding devices, known as jigs or fixtures. They can

help you make cuts more accurately By helping to

steady the workpiece and keep you away from the blade,

they can help you safely use your saw for certain cuts

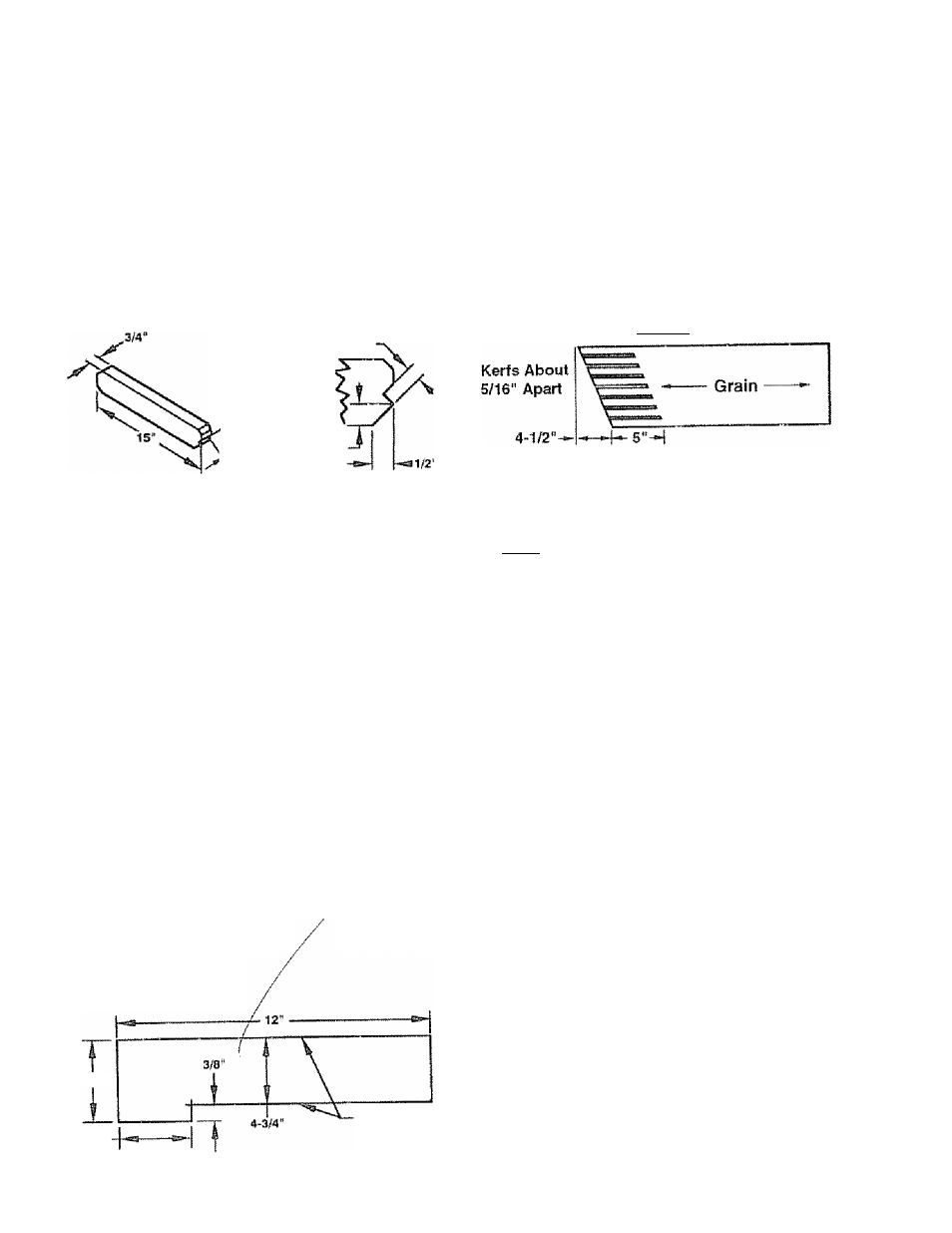

Push Stick

Make the push stick using a piece of 1 x 2 x 3/4 thick

soiid wood.

Slightly Less Than Thickness

Of Workpiece Up To 3/8”

r -

1-S/B"

V

[

SO“ Notch 1/2

NOTE: All dimensions in inches

Push Block

Xhere are any number of ways to properly cut your work

pieces to make a push block. The following steps

describe one way you can make a push block.

Making the base:

* Start with a piece of 3/8 inch plywood at least 5-5/8

inches wide or wider and 12 inches long or longer

® Make two ripcuts Perform the first ripcut along the

side of the 3/8" wide strip Next, ripcut the 3/8“ plywood

to a width of 5-1/8".

• Crosscut the 3/8“ plywood to 12" long.

♦ Crosscut a 2-1/2" piece off the 3/8" wide by 3/8" thick

strip and save this short piece for later,

»The next cuts wilt create the 3/8" by 9-1/2“ notch in the

base Mark the long edge of the board 2-1/2" from one

end Make a crosscut into the edge on the mark, stop

ping about 3/4“ into the board Set the saw and rip the

width to 4-3/4" along the same edge as the stopped

crosscut. Stop the ripcut where the two cuts intersect.

Turn off the saw and remove the ba^ piece. The base

should now measure as shown

Finished Base

5-1/0

a-1/2

Many people custom build their own jigs and fixtures

Jigs and fixtures are often designed for a particular cut

You can use your table saw to easily make many jigs and

fixtures To get you started, we've included Instructions

for some simple ones After you have made a tew prac

tice cuts, make up these jigs before starting any projects.

The use of these devices is explained in "Basic Saw

Operations" section.

These Edges

Must Be

Parallel

Make the featherboard from a 8 x 24 x 3/4 thick solid

wood.

..................... 24"--------------------------H

i

Material for Push Block

»....... ........ __At Least 12"-

3/8" Thick Plywood

Base

-At Least 12 —

3/4“ Thick Plywood

Handle

1

At

S-S/S"

1

Lea!

S-5/8

At Least

S-5/8"

Cutting Out the Base

-2-1/2" {save)

3/0"

4

th cut 1 St Cut

2 nd Cut

T

3rd Cut. S-l/S”

[

Creating the Notch

12

“

1

St

Cut

—-es—j—2-1/2"

2 nd Cut

4-3/4“

OC

П