Adjusting weight transfer, Weight transfer safety information – Great Plains NTA3007HD Operator Manual User Manual

Page 95

Adjustments 91

04/04/2011

166-207M

Adjusting Weight Transfer

Weight Transfer Safety Information

Crushing and High Pressure Fluid Hazards:

This adjustment requires working near the unfolded and low-

ered drill with the hydraulic system active. Assign two people

to this task, one in the tractor cab, ready to shut the tractor

down on hand signal from adjuster or any unplanned event.

High Pressure Fluid Hazard:

Escaping fluid under pressure can penetrate the skin causing

serious injury. Use a piece of paper or cardboard, NOT BODY

PARTS, to check for suspected leaks. Wear protective gloves

and safety glasses or goggles when working with hydraulic

systems. If an accident occurs, seek immediate medical atten-

tion from a physician familiar with this type of injury.

Crushing Hazard:

Keep body parts clear of wings and openers while adjusting.

Keep all bystanders well away. You will be seriously injured or

killed if you are caught between lowering openers and ground,

or raising openers and drill frame.

Falling Hazard - Tires Not a Step:

Do not use tires as steps or platforms. At higher transfers, cyl-

inders can lift main wheels sufficiently for them to spin.

Null4:

Refer to Figure 98

Two dedicated cylinders at the wing pivots can extend to

push the wings down using mainframe/center weight.

These cylinders are in the Lift circuit, and controlled by

an adjustment

/

in the down-pressure valve body.

In conventional till and light no-till conditions, no weight

transfer may be required. In more challenging conditions,

adjust the weight transfer to achieve consistent furrow

preparation, planting depth and furrow closing, while

keeping the wings level with the center section.

Observe all warnings, and take all precautions, as noted

on page 85.

6.

Unfold (page 25) and lower drill (page 32). Put trac-

tor in Park and set parking brake.

7.

Set bypass valve (

, page 88 and adjust down-pres-

sure (

,

, page 86) before adjusting weight trans-

fer.

8.

Lock hydraulic lever forward during field operation for

constant hydraulic flow to openers. See step 2 on

page 87 for details.

9.

Release lock disk

. Adjust knob

clockwise to

increase weight transfer, and counterclockwise to

reduce weight transfer.

The recommended weight transfer pressure ranges for

drilling are:

10. Once pressure is set, secure knobs with lock

disks

.

11. Observe drill operation, and re-adjust down-pressure

as necessary.

Null4:

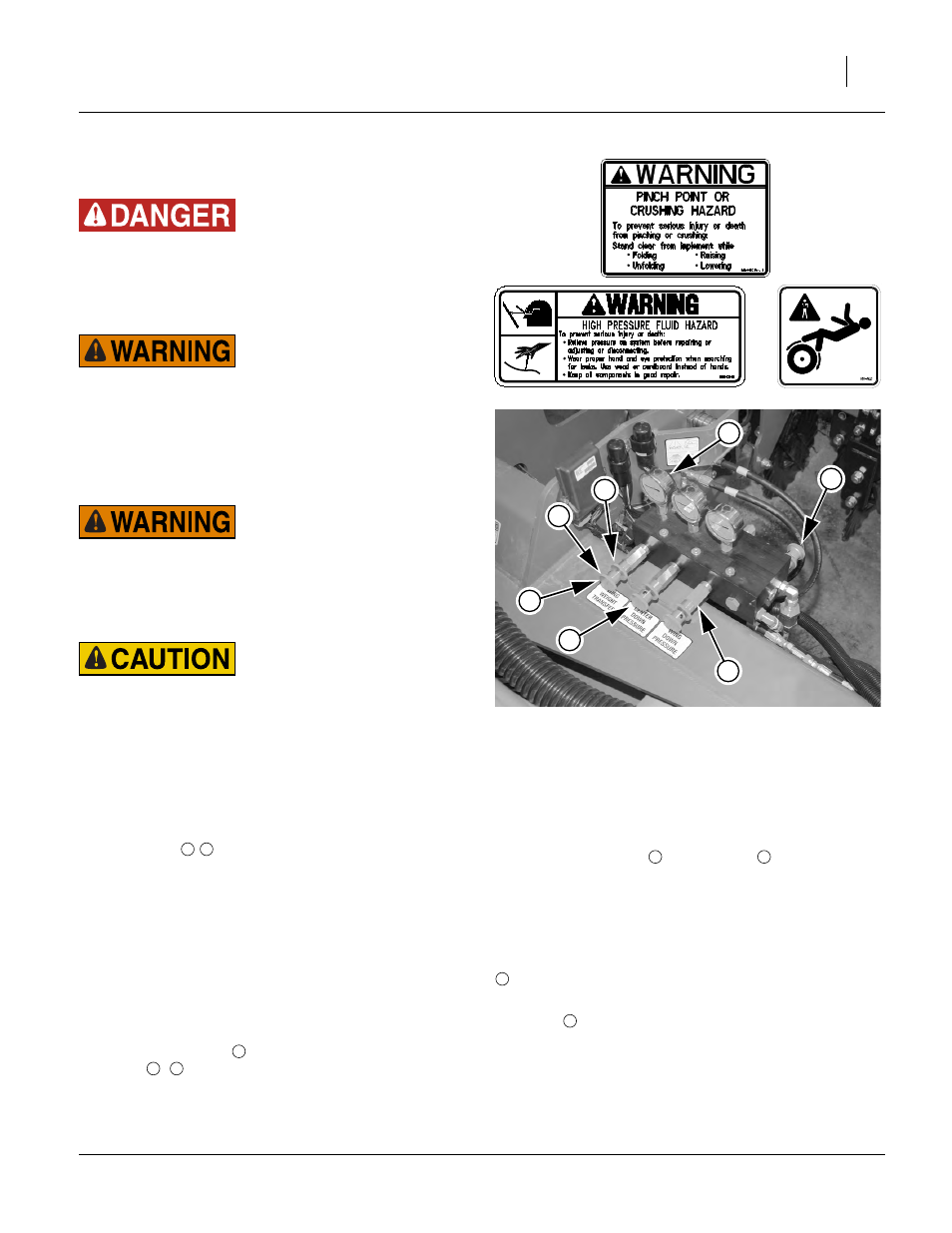

Figure 98

Weight Transfer Adjustment

29422

W

C

T

B

k

r

t

T

t

B

C

W

Transfer 70 to 170 bar (1000 to 2400 psi)

r

k

t

r