Calibration crank, Calibration crank safety information, Crank general information – Great Plains NTA3007HD Operator Manual User Manual

Page 61

Operating Instructions 57

04/04/2011

166-207M

Calibration Crank

Calibration Crank Safety Information

Moving Chain Hazard:

Keep all persons except operator away from drill mainframe

during crank operations. Body parts and clothing can get

caught in chains, sprockets and gears, causing serious injury.

When operating the crank from either side of the drill, all parts

of the contact drive system are in motion, including parts out

of sight of the crank operator.

Rotate the hand crank only in the:

clockwise direction on the left side, or

counter-clockwise direction on right side.

Operating in reverse can damage meter gear box.

Note: If a variable rate gearbox is set to “0”, operating the

hand crank may fail to clear the meters of seed.

Crank General Information

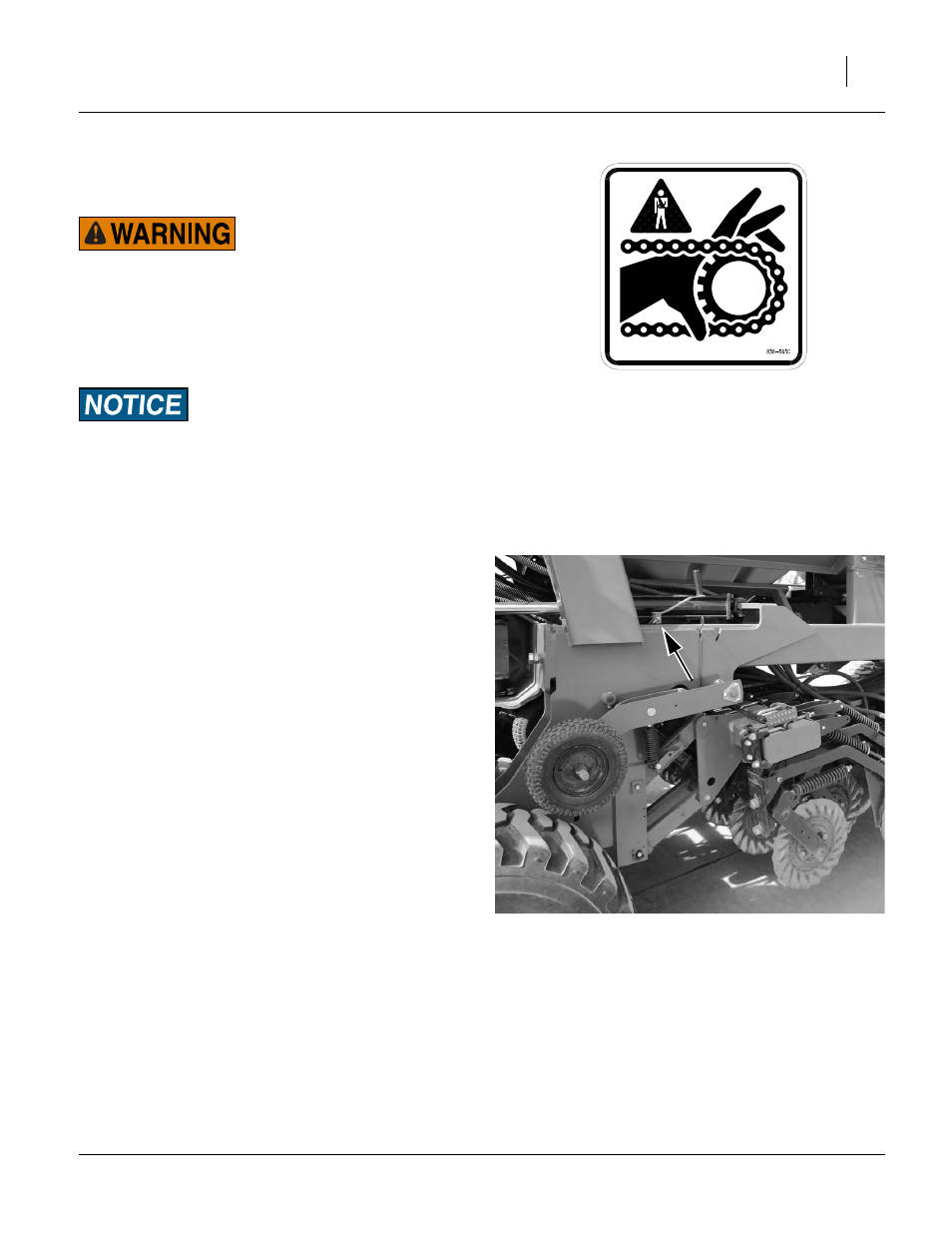

Refer to Figure 65

A hand crank is provided on the left side of the drill for

manual operation of the meters (the meters otherwise

turn only when the drill is lowered and in motion).

The crank is used for two common tasks:

• calibration of the meter setting for planting, and

• clean-out of the meter flute chamber.

Null4:

Figure 65

Hand Crank in Storage

29416