Contact drive adjustment – Great Plains NTA3007HD Operator Manual User Manual

Page 85

Adjustments 81

04/04/2011

166-207M

19. Refer to the seed rate chart for Seed Rate gearbox

setting values for the new chart rate.

Null4:

20. Adjust the control arm to the Gearbox Setting closest

to the NewChart rate.

21. Run the calibration again, starting at step 9, using

the new Variable Rate Gearbox scale setting.

This validates the gearbox adjustment, and estab-

lishes a new, more precise Calibration Constant.

22. With the present meter satisfactorily calibrated, re-

mount the final drive gear removed from the other

hopper.

23. Repeat the calibration procedure for the other hop-

per, starting at step 1.

24. Remove and store the calibration crank.

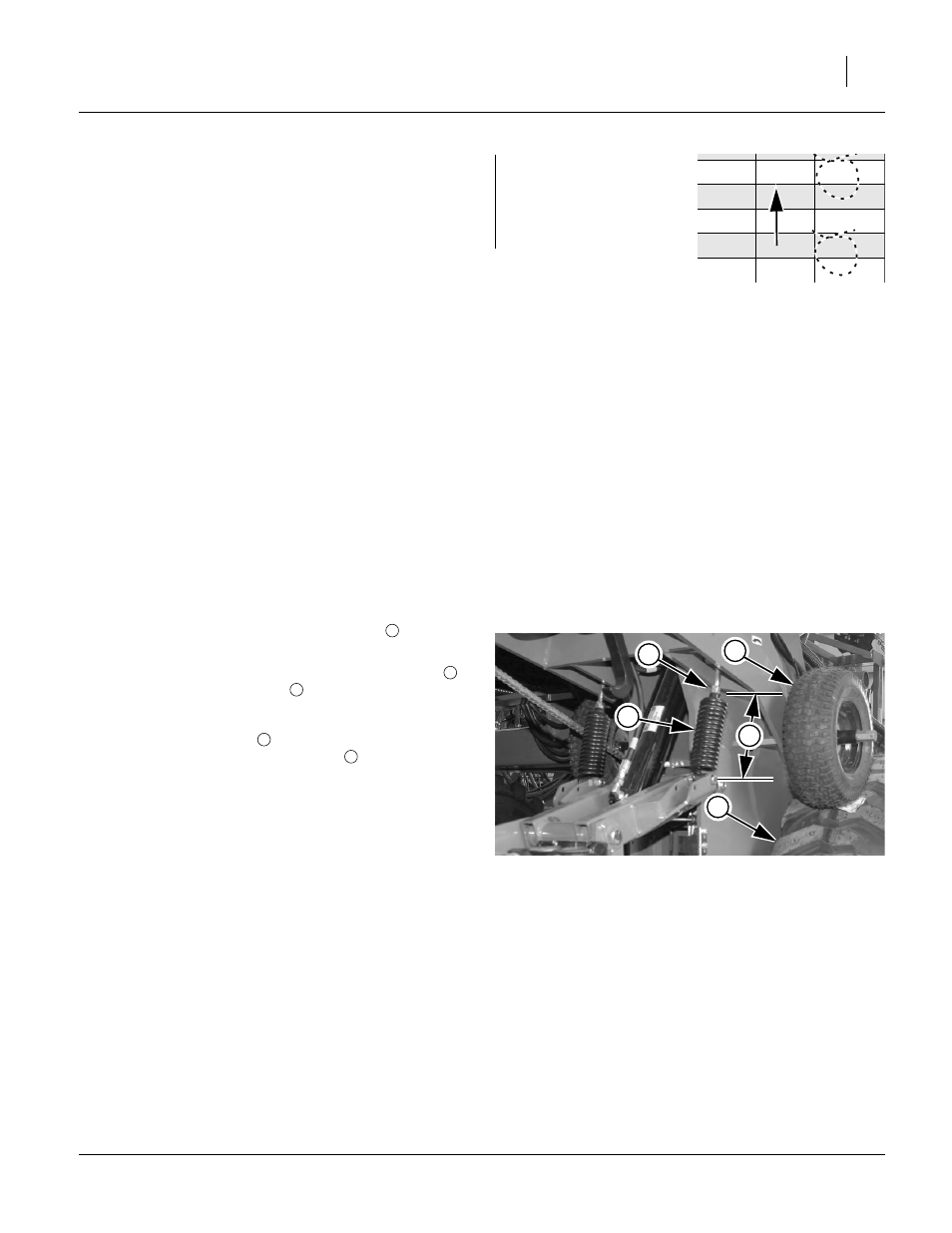

Contact Drive Adjustment

Refer to Figure 86 and Figure 87

There are two contract drive tension springs

side of the drill; four total. If there seems to be:

• insufficient traction between the contact drive tires

and the main transport tires

• excess spring force at contact tires, or

• or a contact drive shaft

is below the minimum clear-

ance when raised in the frame slots

,

then follow these steps:

1.

Check tire size and inflation (page 145).

Use tire sizes specified by Great Plains, at recom-

mended pressures. The remaining steps of this sec-

tion cannot be used to compensate for incorrect

sizes and/or inflation.

49.2

31

77260

158.5

177.6

58

52.7

32

77341

163.7

183.5

59

56.3

33

77413

169.0

189.4

60

60.0

34

77479

174.3

195.4

61

63.7

35

77538

179.6

201.3

62

Example:

NewChart rate to use:

183.5

New Gearbox Setting:

59

Note: The rate of the arm adjusting crank is more than

one scale degree per turn, and the crank can only

be pinned at quarter turns. Pin it when the indica-

tor is closest to the desired setting.

Null4:

Figure 86

Contact Drive Springs

29591

2

7

3

6

1

2

3

4

5