Great Plains NTA3007HD Operator Manual User Manual

Page 84

80 NTA907HD or NTA3007HD

166-207M

04/04/2011

11. Turn the calibration crank for the number of turns to

simulate

1

⁄

10

hectare (or

1

⁄

10

acre).

Note: It is important to turn the calibration crank rapidly.

Use a comfortable speed not exceeding

2 revolutions per second, which would simulate

10 kph (6.2 mph) planting speed. A longer calibra-

tion is always more accurate, especially for low

rates and small seeds.

1

⁄

10

hectare is easy to calcu-

late and is a minimum calibration run.

See table at right for revolutions per area.

12. Wipe all the material off the flanges around the

meter doors and capture that material in the calibra-

tion container.

13. Accurately weigh the container plus material.

14. Subtract the empty container weight to determine

the application rate for

1

⁄

10

acre (or

1

⁄

10

hectare).

15. Press the Stop softkey

on the monitor

and enter the sample net weight (SampleWeight).

The monitor responds with a Calibration Constant.

Push the Save softkey

to accept this

value.

16. Multiply the sample size by 10 to determine applica-

tion rate per acre (hectare) at the current variable

rate gearbox setting.

If the calibrated rate matches the target rate, skip to

step 22. Otherwise…

17. Subtract the calibrated rate per acre (or hectare)

from the target rate to determine a rate correction

difference.

18. Determine a new chart rate, based on the previous

chart (not target) rate. To lower for the next rate:

To raise for the next rate:

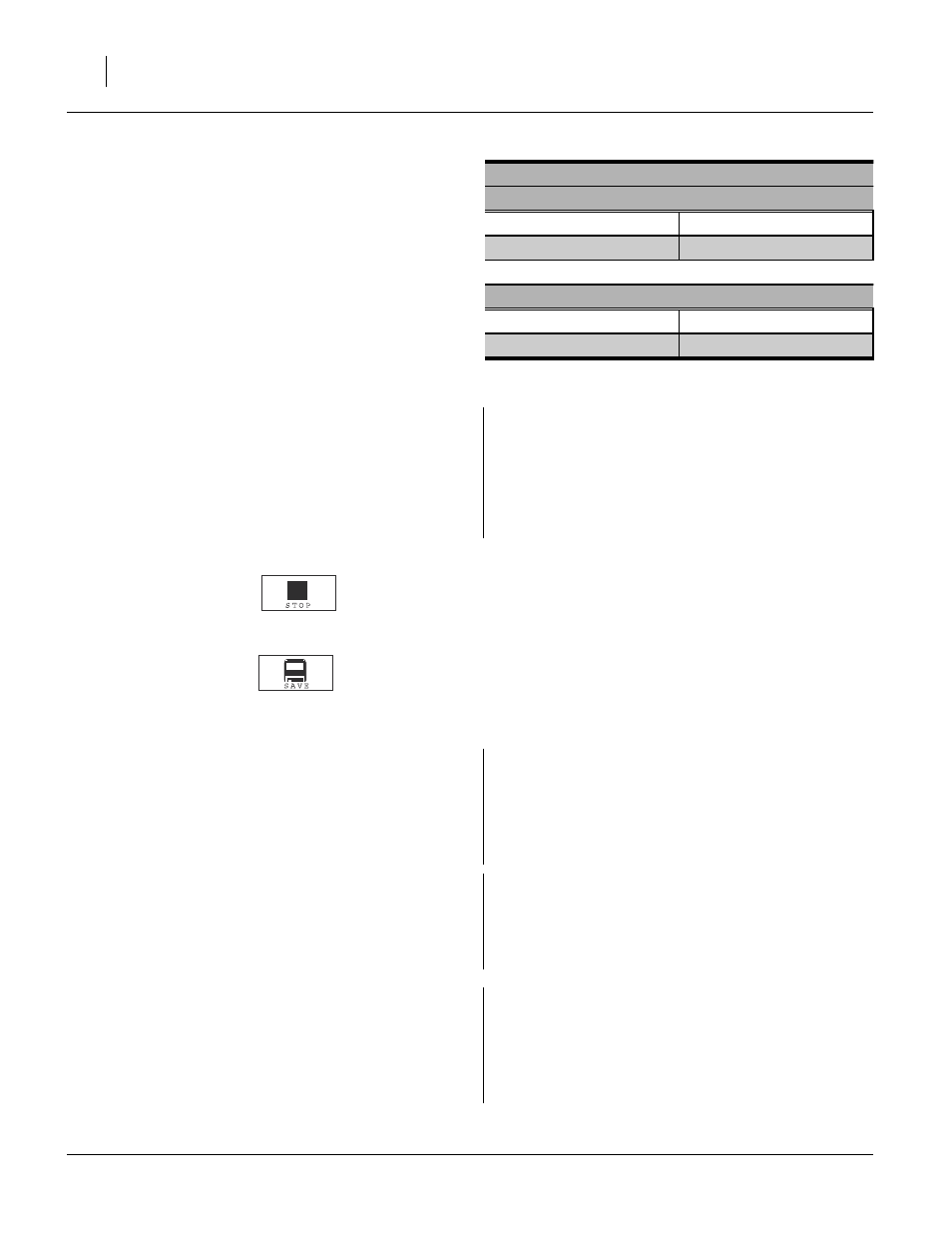

Calibration Crank Revolutions

NTA907HD

Revs/hectare

1050

Per 1/10th ha

105

NTA3007HD

Revs/acre

425

Per 1/10th ac

42.5

Example:

MeasuredWeight is 23.3 kg

for container plus sample

ContainerWeight is 1.52 kg

SampleWeight = 23.3 - 1.5, which is:

21.7 kg

SampleWeight

MeasuredWeight

ContainerWeight

–

=

Example:

CalibratedRate = 21.7 x 10, which is:

217 kg/ha

This is 8% higher than our target rate of 200 kg/ha.

However, because the gearbox actuator effect is not lin-

ear, we cannot simply adjust it 8%.

CalibratedRate

SampleWeight

10

×

=

Example: TargetRate = 200

RateDifference = 217 - 200,

which is: 17 kg

The calibration run metered 17 kg too much.

You must lower the gearbox setting to compensate.

RateDifference

T

etR

arg

ate

CalibratedRate

–

=

Example: Need to lower

RateDifference = 17 kg

OldChart = 201.3

NewChart = 201.3 - 17, which is:

183.9

nearest chart value is: 183.5

NewChart

OldChart

RateDifference

–

=

NewChart

OldChart

RateDifference

+

=