Marker adjustments, Marker disk adjustment, Mark width – Great Plains NTA3007HD Operator Manual User Manual

Page 103: Direction of cut, 21 n w t

Adjustments 99

04/04/2011

166-207M

Marker Adjustments

Review “Marker Safety Information” on page 61 before

adjusting markers. There are four operating adjustments

for markers:

• Disk Angle

Even if your row spacing rarely changes, you may

need to adjust disk angle for soil conditions and plant-

ing speed.

• Marker Extension

(in “Appendix B - Initial Setup”, page 163)

Once set for a specific row spacing, this only needs

periodic checking to ensure the clamp is secure.

• Chain Length

(in “Maintenance and Lubrication”, page 132)

You may want to adjust the chain length to ensure the

markers track uneven ground, and do not drag exces-

sively when markers are folded.

• Marker Speed

(in “Appendix B - Initial Setup”, page 163)

Once initially set by your dealer, this rarely needs

modification.

There are also two maintenance items for markers:

“Marker Hydraulic Bleeding” on page 131

“Marker Shear Bolt” on page 131

Marker Disk Adjustment

Marker disks may be sharp. Use caution when making adjust-

ments in this area.

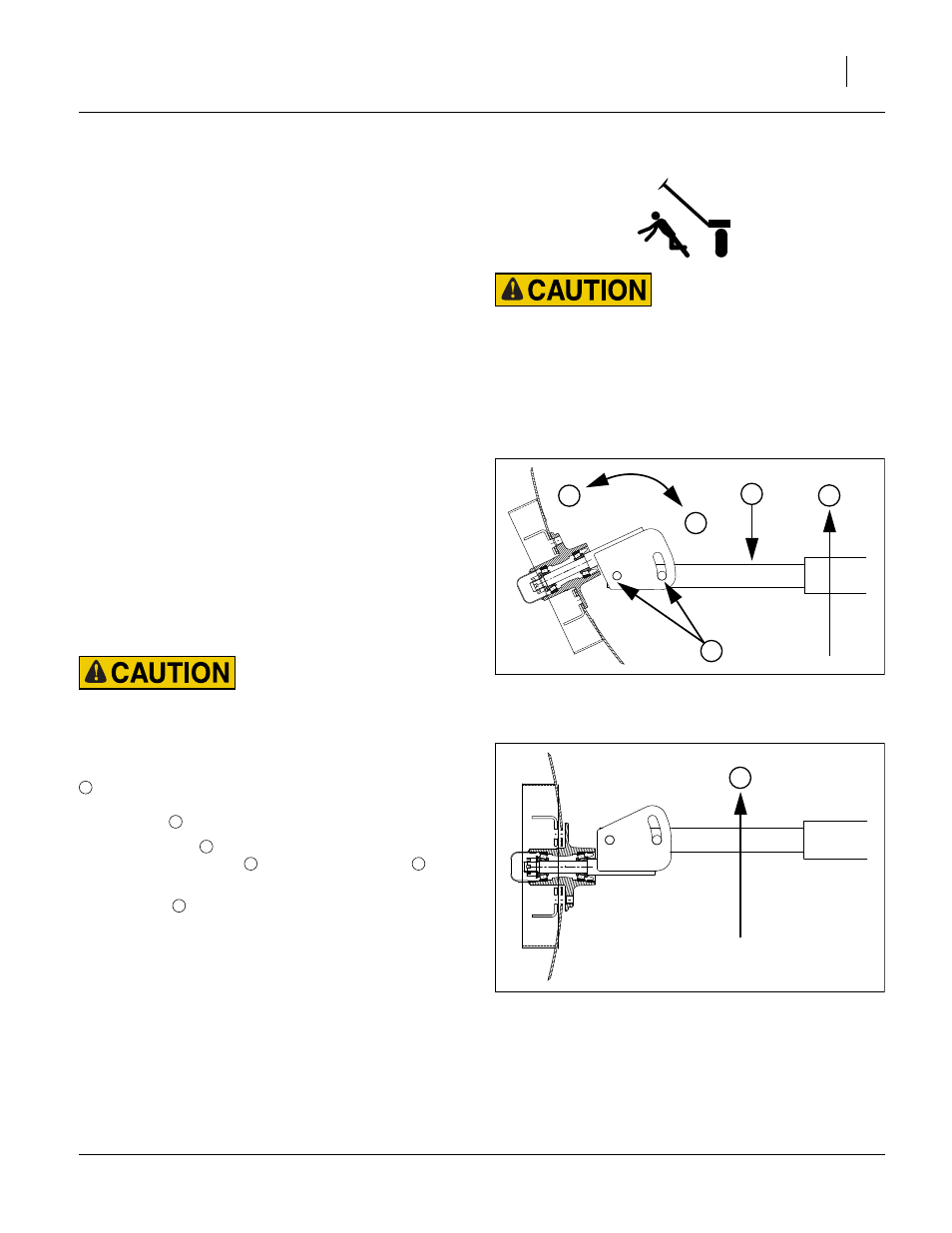

Mark Width

Refer to Figure 109

is the direction of travel.

To change angle of cut, and the width of the mark, loosen

1

⁄

2

-inch bolts

holding the disk assembly.

For a wider mark

, increase the angle of the marker

with respect to the tube

. For a narrower mark

,

reduce the angle.

Tighten bolts

.

Direction of Cut

To have the marker throw dirt out, invert the disk on the

spindle, and invert the disk assembly.

MetaData: End of Adjustments

You may be injured if hit by a folding or unfolding marker.

Markers may fall quickly and unexpectedly if the hydraulics

fail. Never allow anyone near the drill when folding or unfold-

ing the markers.

Null4:

Figure 109

Marker Disk Angle

11757

T

2

1

N

W

T

Null4:

Figure 110

Marker Disk Inverted

11248

T

T

2

W

1

N

2