Tool bar heights – Great Plains NTA3007HD Operator Manual User Manual

Page 133

Maintenance and Lubrication 129

04/04/2011

166-207M

Tool Bar Heights

Tool bar heights must be checked and adjusted in repre-

sentative field conditions, with openers lowered to plant-

ing height, and pulled forward in the ground, as for

section alignment checking above. New drills are

shipped with the wing eyebolts not fully tightened. They

must be set before first planting.

9.

Check that rows are fully lowered, running level, and

that center front and wing gauge wheels are not run-

ning light. Adjust down-pressure and weight transfer

as needed (page 85).

If rows are not running level, adjust sub-frame shims

as needed (page 90).

Refer to Figure 146 (shown with wings folded for clarity)

10. Check opener sub-frame tool bar height at the center

section. Measure from the average soil surface level

to the bottom of the rear opener tool bar.

The distance should be:

76.2cm (30in).

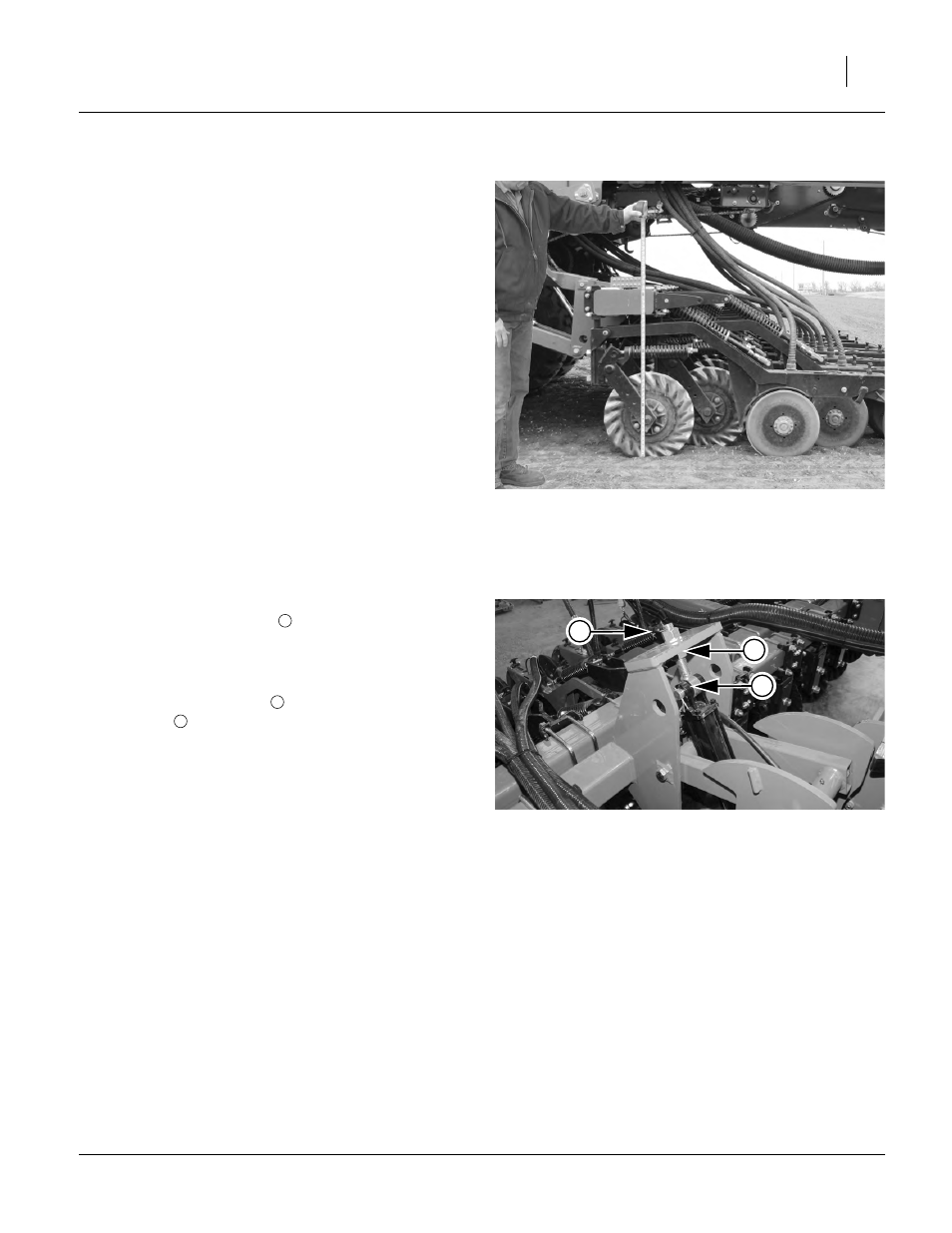

Refer to Figure 147

11. Check sub-frame tool bar height at the inside and

outside ends of the wing rear tool bar. If either end

differs from center height by more than about 6mm

(

1

⁄

4

in), adjust the eyebolt

above the parallel arms

at that end.

12. To adjust an eyebolt:

Back the upper jam nut

up a few turns. Adjust the

lower nut

. The adjustment is about 2.8mm

(0.11in) of opener height per turn of the adjuster nut.

Whether adjusted or not, secure the 1-8 jam nut to

torque spec (page 154).

13. Check and set all four (4) wing ends and eyebolts.

14. Pull forward and re-check height.

Null4:

Figure 146

Checking Tool Bar Height

29519

Null4:

Figure 147

Adjusting Wing Tool Bar Height

29520

3

1

2