Great Plains NTA3007HD Operator Manual User Manual

Page 83

Adjustments 79

04/04/2011

166-207M

Insert calibration crank onto contact wheel shaft.

See “Calibration Crank” on page 57.

Rotate the calibration crank only in the:

CLOCKWISE direction on drill left, or;

COUNTERCLOCKWISE direction on drill right.

Operating in reverse can cause gearbox damage.

6.

Turn the calibration crank enough turns to be sure

the meter flutes are full and the system is metering.

Obey manufacturer or grower recommendations for safety

equipment and protective gear when using treated seeds.

7.

Wipe all material off the flanges around the meter

door.

8.

Accurately weigh an empty container large enough

to catch material coming out of the meter. The cali-

bration bag supplied with your drill weighs 1.53 kg

(3.36 lbs).

Refer to Figure 85

9.

Place container under open calibration door. If using

the calibration bag, loop bag handles over the door

handles and hook the bag to the front of the meter.

10. On the seed monitor terminal,

set the monitor to Calibration mode

.

enter [ 5 ] for the “# Meter Revs”, and

press the Start softkey

.

This “# Meter Revs” parameter does not affect the

monitor calibration because the monitor counts

actual meter shaft revolutions and uses that count to

compute the Calibration Constant.

The “# Meter Revs” parameter is used for a progress

bar displayed during calibration.

Null4:

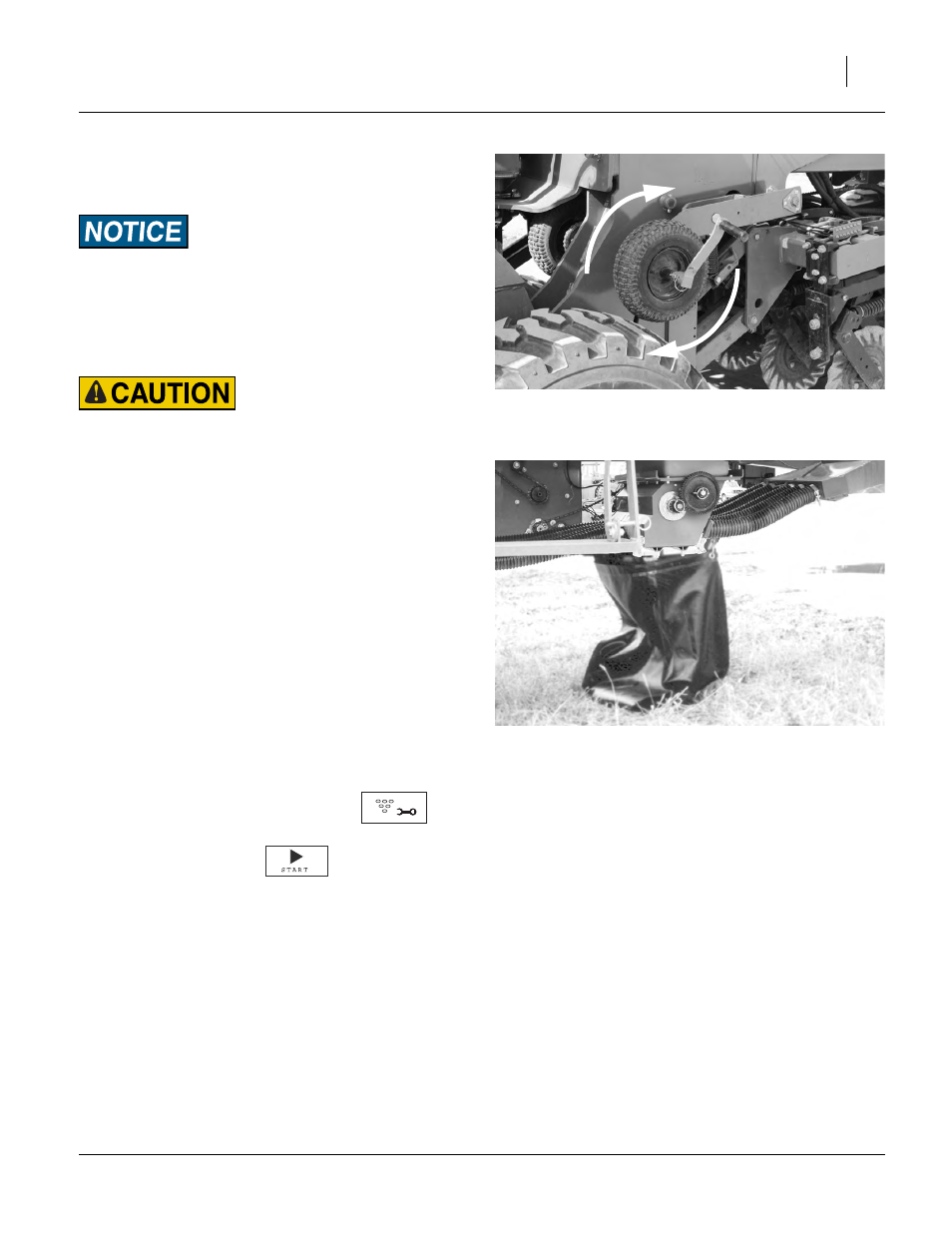

Figure 84

Calibration Cranking, Left Side

29417

Null4:

Figure 85

Calibration Bag

26402