Bleeding tilt hydraulics – Great Plains NTA3007HD Operator Manual User Manual

Page 117

Maintenance and Lubrication 113

04/04/2011

166-207M

Bleeding Tilt Hydraulics

This bleed is most conveniently performed with the drill

fully folded into transport configuration.

If bled while tilted up, all four (4) transport locks must be

in ROAD position, and pins must be engaged behind piv-

oting plates. See “Folding the Air Drill” on page 34.

1.

Review safety advisories and operational advice on

page 112, and on this page, before performing

bleed.

Refer to Figure 114

2.

Set transport locks to ROAD.

Set FTM MASTER and Tilt switches on.

Tilt wings up.

Set circuit to Neutral.

3.

Verify that transport locks have engaged.

Set circuit to Float to relieve pressure in lines, and

tension at cylinder rod ends.

Refer to Figure 115

4.

Un-pin cylinder rod ends. Support rod ends so that

they cannot strike drill parts, or ground, during exten-

sion.

5.

Fully retract circuit.

Set circuit to Neutral.

6.

Carefully loosen JIC fittings @ at cylinder rod ends.

7.

Slowly retract circuit again, watching for fluid at each

cracked fitting.

8.

As fluid appears, set circuit to Neutral and secure fit-

ting. Retract again. Repeat until all four rod ends are

secured.

9.

Fully Extend tilt cylinders.

Set circuit to Neutral.

10. Carefully loosen JIC fittings @ at cylinder base ends.

11. Slowly extend circuit again, watching for fluid at each

cracked fitting.

12. As fluid appears, set circuit to Neutral and secure fit-

ting. Extend again. Repeat until all four rod ends are

secured.

13. Use tractor circuit to re-position rod ends and re-pin.

Crushing Hazard:

Wings must be fully tilted up, with transport locks engaged,

before performing a tilt bleed using this method. Verify that

lock pins are engaged behind pivoting arm weldments before

setting circuit to Float.

Null4:

Figure 114

CFM Tilt Enable for Bleed

29380

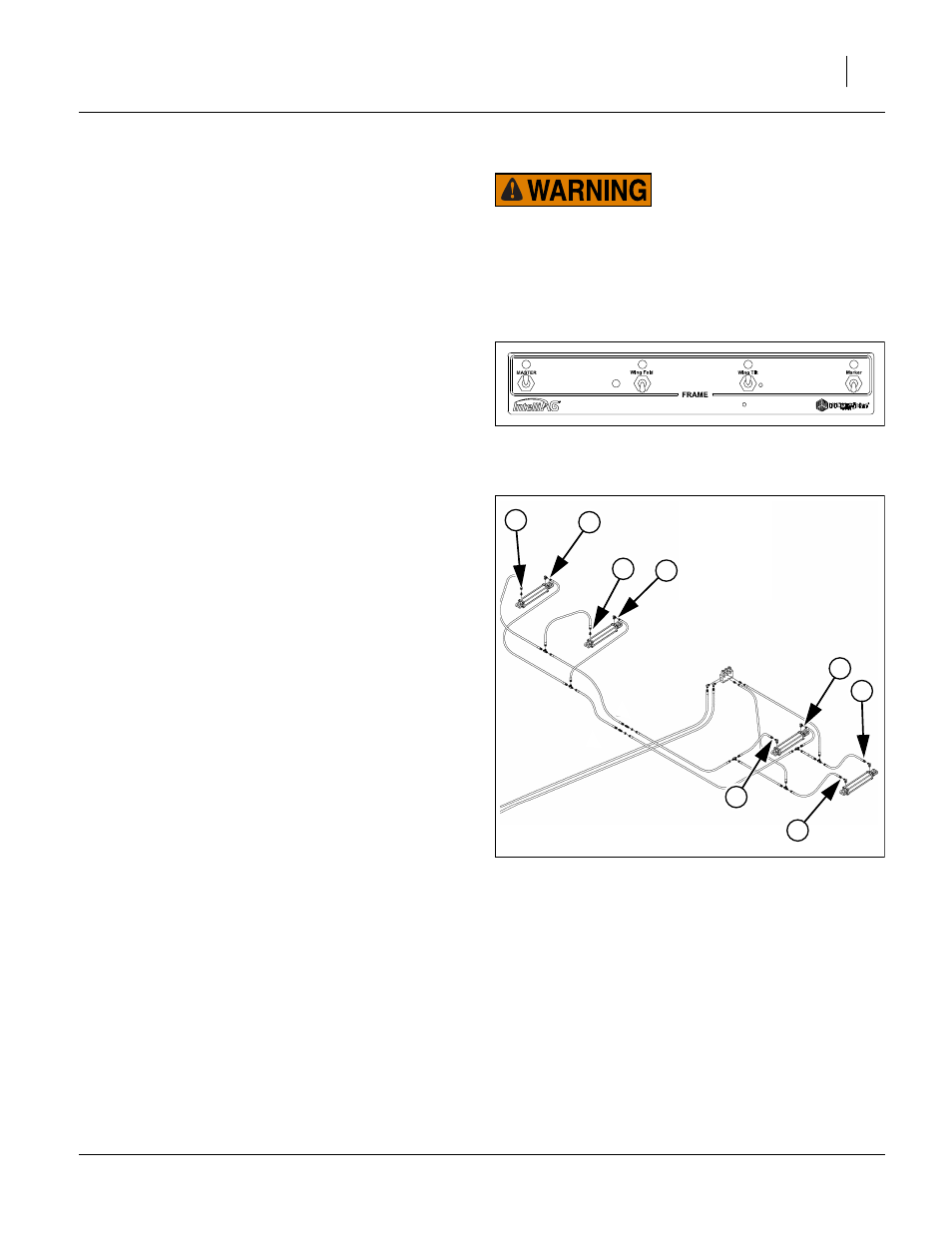

Null4:

Figure 115

Tilt Bleed Points

29476

1

2