And 3-point height, Manual gauge wheel height, 86 and tr – Great Plains NP30A 30-foot Operator Manual User Manual

Page 90

86

NP30A or NP40A

Great Plains Manufacturing, Inc.

407-502M

2014-05-20

2- and 3-Point Height

This applies to 2-point and 3-point applicators only.

Center section tool bar height is set by the tractor hitch.

Wing end tool bar height is set by independent gauge

wheels on each wing end.

1.

Move to smooth level ground with soil as similar as

possible to field conditions. Set tractor brakes.

2.

Using grease pen or similar, mark the desired soil

level on a knife or tine near the left outside row, but

not in the tire track (knives or tines in tracks run

shallower than other rows).

3.

Raise the applicator (page 52 or page 51).

4.

Unfold the applicator (page 58).

5.

Lower the applicator until the center section knives

or tines are just above the ground. Set circuit to

Neutral to hold this height.

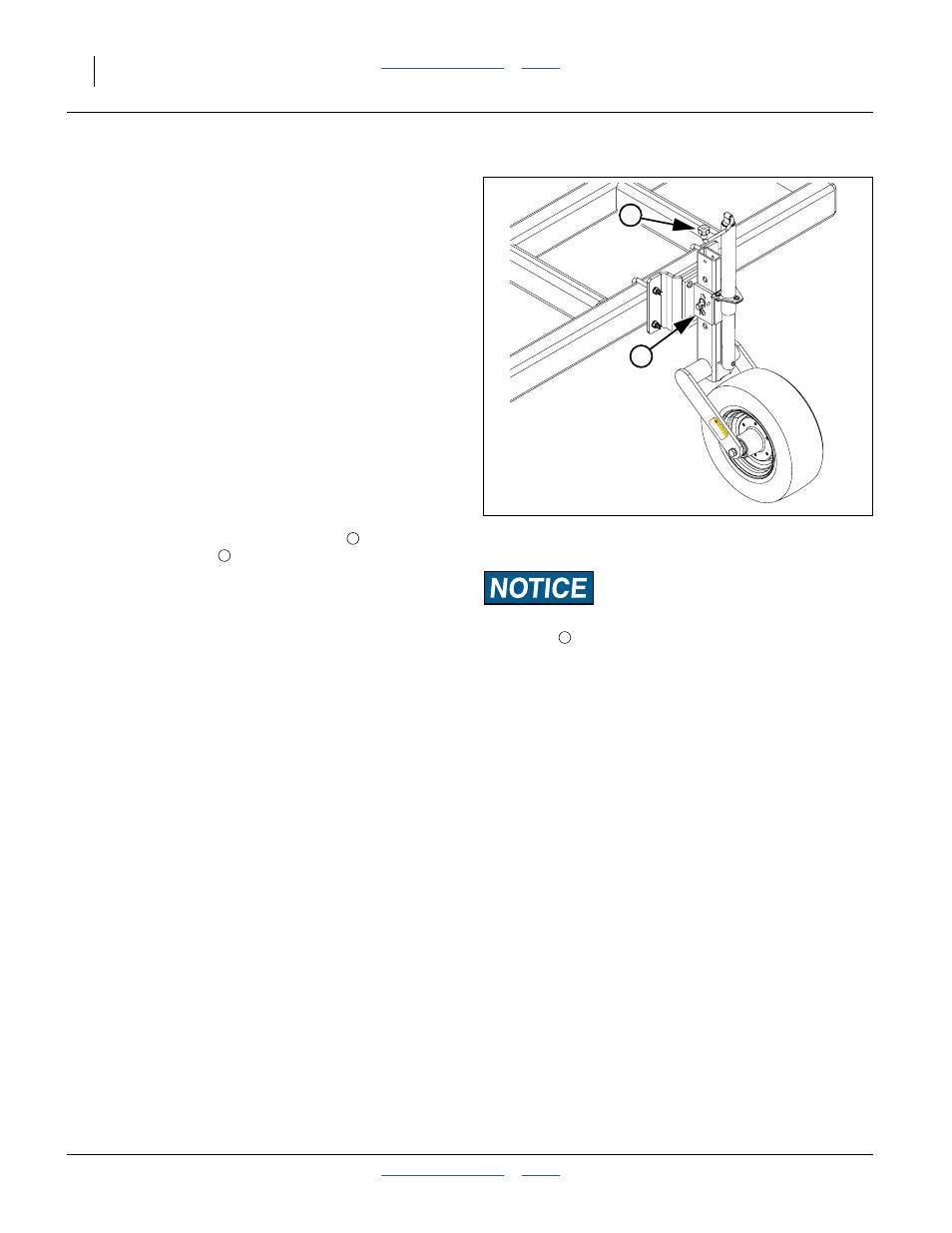

Manual Gauge Wheel Height

Refer to Figure 67

6.

At each gauge wheel, use the crank

to remove

tension at the pin

. Remove the pin.

7.

Adjust the wheel height to bring the wing knives or

tines to the same height as the center section knives

or tines (just above the ground).

8.

Lower the applicator (page 52 or page 51) until the

center section knives or tines are resting on the

ground.

9.

Use the gauge wheel cranks to raise the wheels until

the clearance under the bottom of the tires equals

the desired knife/tine depth (to shoe bottom).

10. Use the crank to bring one set of mount and tube

holes into alignment. Insert and secure pins.

11. Pull forward, lowering the center section until all

sections are level from left to right.

12. Measure the depth at which the knives or tines are

running. If the knives or tines are at the desired

depth, no further adjustment is necessary. Skip to

step 14.

13. If wing tip height needs to be adjusted, raise the

applicator slightly as needed, remove pins and

adjust gauge wheel height. Re-pin. Recheck per

step 12.

14. Adjust hitch height until center section knife or tine

depth matches wings, and applicator is level.

Capture this hitch setting.

Equipment Damage Risk:

Use the pin

. Crank the tube up against the pin. Wheel loads

transmitted to the crank can damage the crank.

Note: Turn crank clockwise to raise applicator (lower

wheel), and counterclockwise to lower applicator

(raise wheel).

Note: At maximum height, the knives or tines are off the

ground. This configuration is useful for unfolded

parking, storage and service.

Make a record of the setting needed for field

height prior to setting for maximum.

Figure 67

Gauge Wheel Adjustment

31732

6

83

8-59

5C

T

or

q

ue wheel bolts

t

o 120 lb-ft.

Ma

x

imu

m

in

flation

p

res

su

re

of t

ires

is

90

p

s

i.

T

o

Av

oi

d In

ju

ry

or

Ma

c

h

ine Dam

a

ge

f

ro

m

Impr

oper

Ti

re

In

flation

o

r T

o

rqui

n

g o

f W

h

ee

l B

olts

:

CA

UTION

6

5

5

6