Great Plains NP30A 30-foot Operator Manual User Manual

Page 105

Great Plains Manufacturing, Inc.

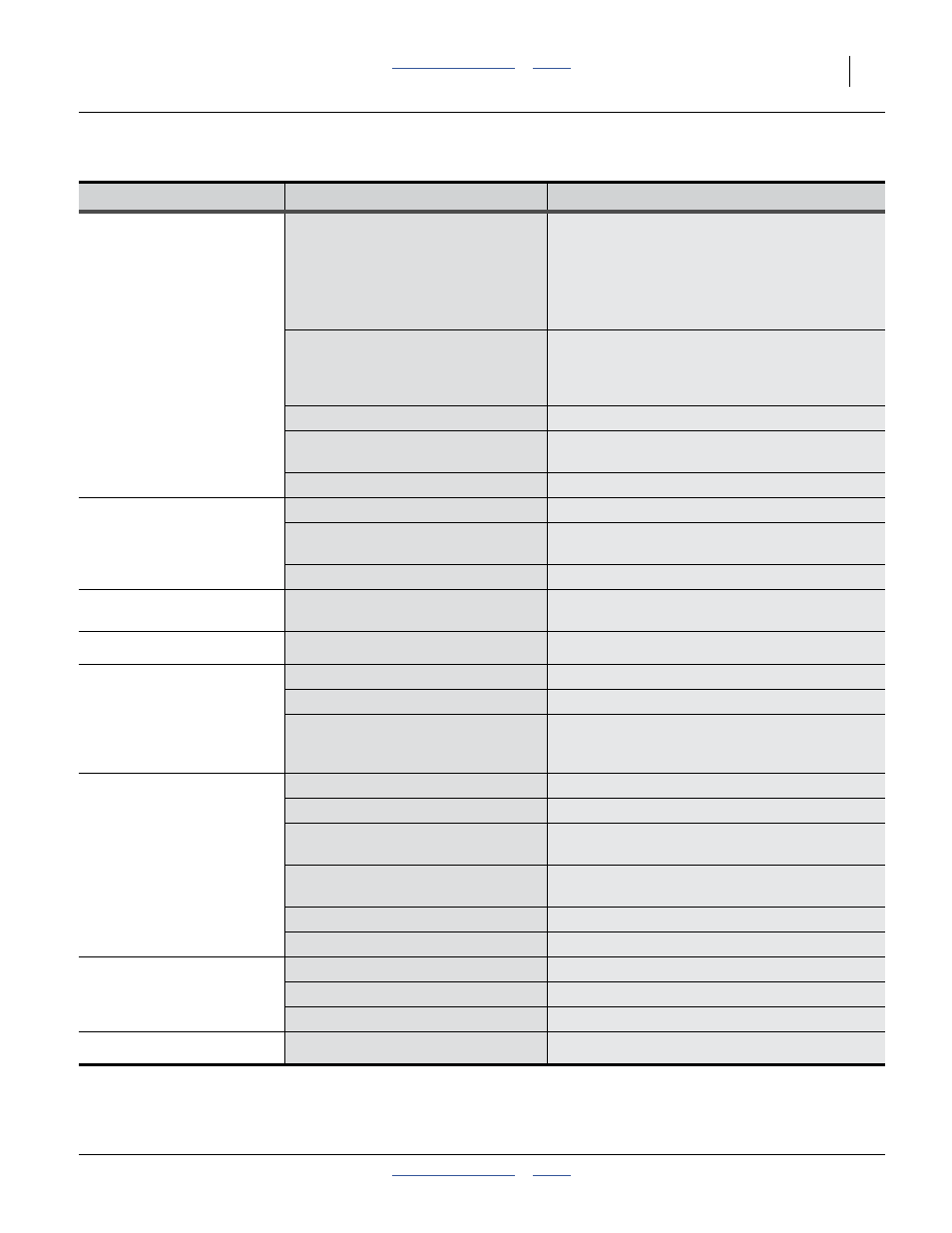

Troubleshooting

101

2014-05-20

407-502M

NH

3

loss to atmosphere

(one row)

Plugged knife or tine

See “Clearing Plugged Knives or Tines” on

page 112.

If knives or tines are plugging frequently, check:

coulter setup, application depth, knife/tine wear.

Field conditions and weather may also be

unsuitable at the moment.

Disconnected delivery or vapor line

Treat this as knife or tine plugging (page 112)

until the cause is determined. If the cause is tall

tough field trash, consider re-working the field if

disconnects are frequent.

Knife shear bolt failed

Sealer mis-adjusted or failed (such

as a broken spring)

Check sealer. Adjust (page 97) or repair.

Rows in tractor tracks too shallow

Reset tractor wheel spacing to avoid rows.

Uneven application

depth

Excessive field speed.

Reduce field speed.

Incorrect coulter depth setting.

Set coulters to depth of knife or tine shoes

(page 94).

Rough application conditions.

Rework the field.

Wings too Shallow

Insufficient weight transferred to

wings

Increase weight transfer (page 87).

Center too Shallow

Excess weight transferred to wings

Decrease weight transfer (page 87).

Knives or tines

plugging frequently

Knives or tines worn

Replace worn knives or tines.

Field too wet

Wait for drier conditions.

Tractor rocking backward during

stops, or lift sequence pushing

knives or tines backward

Refine stopping and/or lifting technique to avoid

reverse knife or tine motion.

Sealers plugging

Conditions too wet.

Wait for drier conditions.

Too much pressure on row-units.

Reduce spring pressure.

Coulters set too deep, bring up

excess dirt and moisture.

Check coulter adjustment.

Fertilizer Applicator not level from

front to rear

Check applicator front-to-back level (page 37).

Failed bearings

Replace bearings.

Disc blades worn

Replace disc blades.

Sealers not compacting

the soil as desired.

Sealer adjustment not optimal.

Not level front to rear.

Check applicator front-to-back level (page 37).

Too wet or cloddy

Wait until drier weather or rework ground.

2-Point Lift-Assist slow

Adjustment valve not fully open.

Open valve (page 155).

General Applicator Troubleshooting

Problem

Cause

Solution