Anhydrous coulter spring setting, Anhydrous coulter castering, Anhydrous coulter blade wear – Great Plains NP30A 30-foot Operator Manual User Manual

Page 100

96

NP30A or NP40A

Great Plains Manufacturing, Inc.

407-502M

2014-05-20

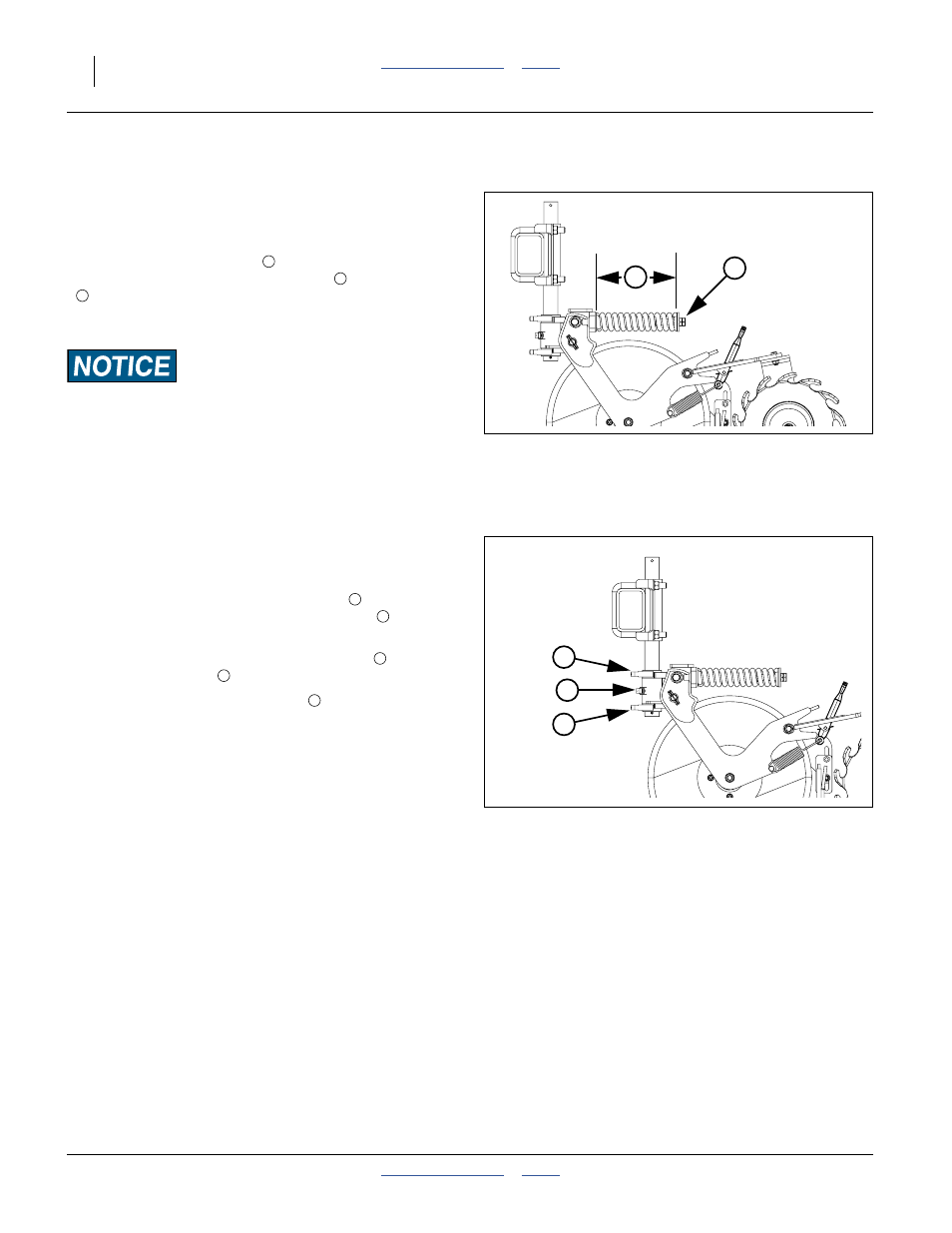

Anhydrous Coulter Spring Setting

If the NH

3

coulter is ever disassembled for maintenance,

reset the spring length to factory setting. Raise the

applicator to ensure that the coulter is relaxed.

Refer to Figure 79

At the rear end of the spring

, loosen the outer jam nut.

Adjust the inner nut for a spring length

of:

10

3

⁄

8

inches (26.4 cm)

This corresponds to a vertical trip force of

1557 pounds (705 kg).

Machine Damage Risk:

Do not attempt to compensate for extreme field conditions by

adjusting the springs to higher forces (shorter springs).

Higher trip force is not likely to improve penetration, and

results in premature blade wear, higher risk of blade damage,

and may simply lift the applicator.

Anhydrous Coulter Castering

Coulters may be operated locked in-line, or with limited

free castering.

Refer to Figure 80

To lock the coulter, loosen the jam nut at

. Align the

coulter front to back. Tighten the set screw at

, then the

jam nut.

To unlock the coulter, loosen the jams nut at

. Loosen

the set screw bolts at

, then tighten the jam nuts.

Note: Do not loosen the stop bolts

.

Anhydrous Coulter Blade Wear

Blade wear is normal and the rate of wear varies with

field conditions and operating depth. Consider replacing

the blade when the initial diameter has been reduced by

1 to 2 inches.

Note: Although a nominal 22 inches in diameter, blades

are lightly larger.

2

1

Figure 79

Coulter Spring Length

34929

1

2

2

b

b

a

Figure 80

Anhydrous Coulter Castering

34929

a

a

a

a

b