Gauge wheel lock channels, Wing lock channels, Gauge wheel lock channels wing lock channels – Great Plains NP30A 30-foot Operator Manual User Manual

Page 49

Great Plains Manufacturing, Inc.

Applicator Operating Instructions

45

2014-05-20

407-502M

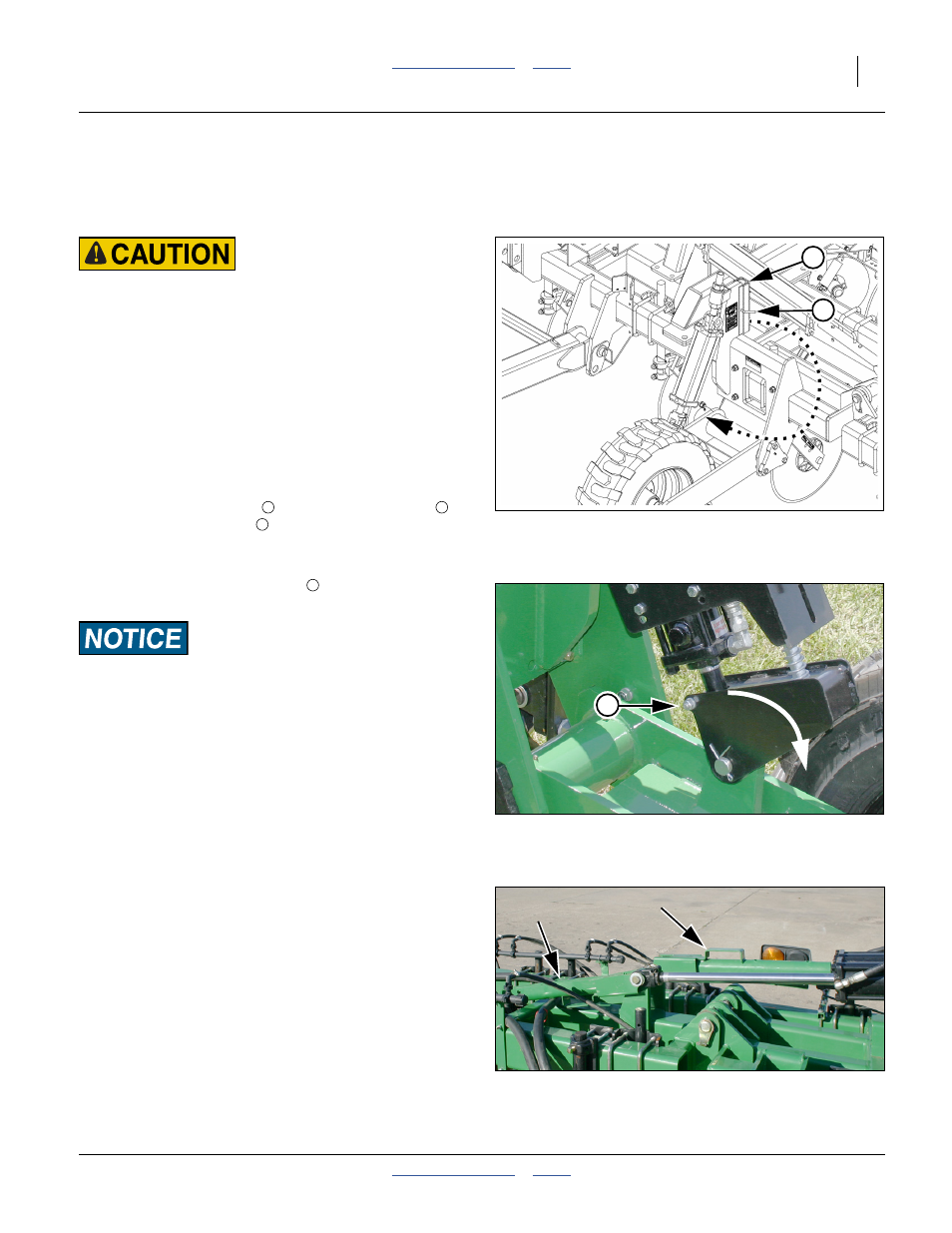

Gauge Wheel Lock Channels

In routine use, install only the center section locks. For

maintenance, install all four. Installing the left wing lock

requires disabling the hydraulic depth stop.

Falling Hazard:

Do not climb or stand on tires or wheels. Even at full extension

on level ground, tires may not be in firm ground contact. They

could spin without warning. A fall could result in serious

injury.

Refer to Figure 24 and Figure 25

To install cylinder stops:

1.

Fully raise applicator (page 48). Set lift circuit to

Neutral.

2.

Install lift-assist locks (page 44).

3.

At each section lift cylinder to be locked, remove

cotter pin and lock pin

. Remove lock channel

from storage location

.

Refer to Figure 26

4.

If locking for maintenance, at the left wing lift

cylinder, remove the rear pin

of the depth stop

clevis. Swing the clevis forward and down.

Machine Damage Risk:

Do not install a lock channel on the depth stop cylinder unless

the clevis has been rotated clear of the cylinder rod. Lowering

the applicator onto a lock channel with the clevis in place will

damage the clevis.

5.

Place a lock channel on the lift cylinder rod of each

cylinder to be locked.

6.

Re-install locking pin and secure with cotter pin.

7.

Lower fertilizer applicator onto lock channels.

8.

Set lift circuit to Float.

Wing Lock Channels

Refer to Figure 27

These lock channels are only present on 2012- NP40A,

NP30A, NP3000 2-point with lift assist and 3-point

models. They enable a partial “gull wing” fold during field

lift. On 2013+ models, this function is controlled by

solenoid valves.

See page 59 for operation.

3

1

Figure 25

Forward Lift Cylinder Lock Channel

31609

_200%

3

1

2

4

Figure 26

Disengage Hydraulic Depth Stop

31742

4

Figure 27:

Wing Lock Channels

31620