Great Plains NP30A 30-foot Operator Manual User Manual

Page 107

Great Plains Manufacturing, Inc.

Troubleshooting

103

2014-05-20

407-502M

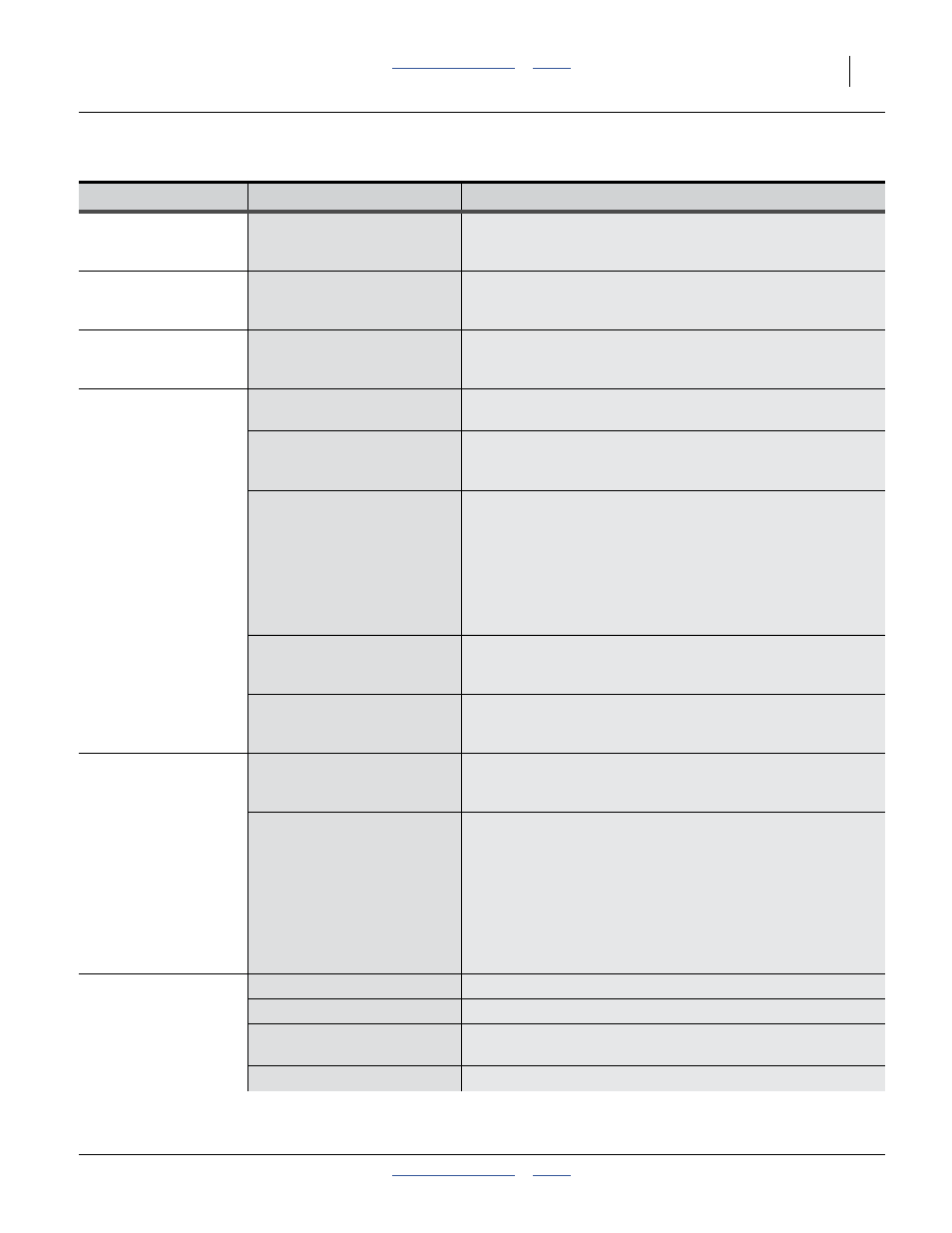

Metering System Troubleshooting

Problem

Cause

Solution

Pressure Spikes

(no alarm)

Plugged knives or tines

Stop application per page 76. Lift applicator and inspect

knives or tines. Clear any plugging per “Clearing Plugged

Knives or Tines” on page 112.

Flow divider

pressure sag

Open delivery line or lines

Stop application per page 76. Lift applicator and inspect

knives or tines for open line plugging. Clear any plugging per

“Clearing Plugged Knives or Tines” on page 112

Temperature Rise

(no alarm)

Plugged refrigerant vapor line Stop application per page 76. Lift applicator and inspect

knives or tines. Clear any plugging per “Clearing Plugged

Knives or Tines” on page 112.

Rate Alarm, Low

System not fully charged

Expect early rate alarms until the cooler is ensuring that all

meter flow is liquid.

One or more manual valves

not fully open

Suspend operations (per page 75). Check all manual valves

from nurse tank withdrawal valve to emergency shut-off

valve.

Solenoid or control valve

malfunction or harness status

Suspend operation (page 75).

Close emergency shut-off valve.

Discharge line from emergency shut-off valve to knives or

tines.

Wait for applicator to be safe to approach.

Check harness connections and fuses.

Use console SELF-TEST mode to command Raven valves

open. Check valve ball indicators at valves.

Field speed too high (higher

than available pressure can

supply NH

3

)

Slow down, or wait for warmer conditions.

Tank pressure low

Ambient or tank temperature may be too low to provide

sufficient delivery pressure. Wait for tank to warm, or wait for

warmer weather.

Rate Alarm, High

Incorrect VALVE CAL for

Control Valve or METER CAL

for flow meter.

Recheck console setup against values provided for

components (page 39).

Control Valve failed, or

harness status

Suspend operation (page 75).

Close emergency shut-off valve.

Discharge line from emergency shut-off valve to knives or

tines.

Wait for applicator to be safe to approach.

Check harness connections and fuses.

Use console SELF-TEST mode to command rate to zero

open. Check valve ball indicators at valves. Command rate

to maximum. Check ball indicator.

Excess NH

3

Remaining

(but no alarms)

Incorrect console setup

Re-check METER CAL and BOOM CAL.

Field size different.

After ruling out metering problems, re-check geography.

Excessive gaps between

fertilizer applicator passes.

Gap between opposing pass end trenches should be one

row space (e.g. 30in)

Flow meter malfunction

Consult dealer.