Clearing plugged vapor tubes, Clearing closed line vapor plugs, Clearing open line vapor plugs – Great Plains NP30A 30-foot Operator Manual User Manual

Page 117: 13 a48

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

113

2014-05-20

407-502M

Clearing Plugged Vapor Tubes

Elevated Ammonia Exposure Hazard:

Follow clearing instructions carefully. Wear your PPE

a

.

Plugged vapor tubes with tubing still attached can contain

significantly greater than normal NH

3

vapor which is not

likely to be mitigated by normal Discharge procedures. Hastily

disconnecting a charged line releases a dangerous amount of

NH

3

vapor. Your PPE is not designed to protect you against

such a release. Burning, respiratory injury, blinding or death

could result.

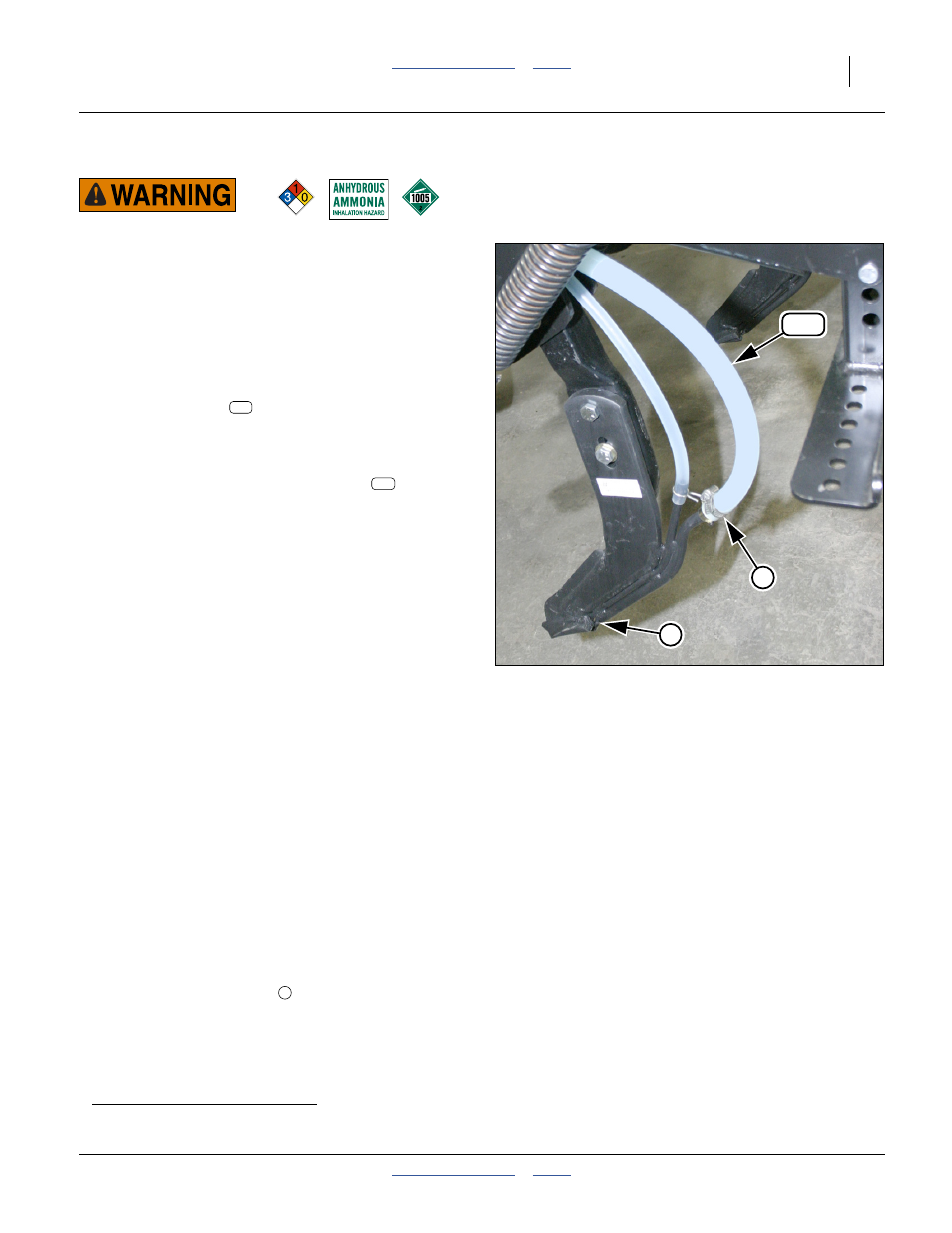

Refer to Figure 89

A plugged vapor tube

often usually does not result in

the vapor tubing lifting off the knife or tine tubing at the

clamp (it is a “closed line plug”).

If only one vapor line is plugged, the symptom may be an

elevated temperature at the cooler gauge (

on

page 21), and possibly a rate alarm if cooling is

insufficient. If both vapor lines at a cooler are plugged (at

moderate or warm ambient temperatures) the

temperature gauge rises higher, and more quickly.

Cooling ceases. Cooler pressure rises. Flow divider

pressure falls. Rate alarm is likely. Normal Discharge

may not clear the line.

If the plugged line disconnects (“open line plug”), you

may see little change from normal operations. Odor is

elevated, if you drive down-wind of application. The

vapor line may not cause a cloud. The change in cooler

pressure may be minor. You are most likely to detect an

open line plugging of a vapor line during routine row

inspection at re-hitch.

Clearing Closed Line Vapor Plugs

1.

Review the WARNING at the top of this page.

2.

Stop operation (page 76).

3.

Discharge the system (page 110). The standard

discharge is not likely to adequately discharge any

plugged, closed, vapor lines. Expect continuing

vapor release at non-plugged rows. The plugged line

discharges back through the cooler, then through the

flow divider and out the other rows.

4.

Wait until the plugged knife or tine has warmed to

ambient temperature, and there is no liquid in the

vapor line.

5.

Loosen the screw clamp

tubing. Pull the vapor tubing off the knife or tine

tubing.

6.

Use a thin flexible tool (a coat hanger wire may

suffice) to clear the knife or tine tube from above or

below.

7.

Reconnect the vapor tubing. Push the vapor tubing

onto the knife or tine tube about

3

⁄

4

inch (19 mm).

Slide the screw clamp to centered in the overlap and

secure.

Clearing Open Line Vapor Plugs

1.

Stop operation (page 76).

2.

Discharge the system (page 110).

3.

If the knife or tine tubing is cold, wait for it to warm to

ambient temperature (and vaporize any liquid NH

3

inside).

4.

Use a thin flexible tool (a coat hanger may suffice) to

clear the knife or tine tube from above or below.

5.

Reconnect the vapor tubing. Push the vapor tubing

onto the knife or tine tube about

3

⁄

4

inch (19mm).

Slide the screw clamp to centered in the overlap and

secure.

a. PPE: Personal Protective Equipment

Figure 89

Dual Knife Vapor Tube

31634

3

3