Caster brake adjustment, Pressure plate adjustment – Great Plains NP30A 30-foot Operator Manual User Manual

Page 129

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

125

2014-05-20

407-502M

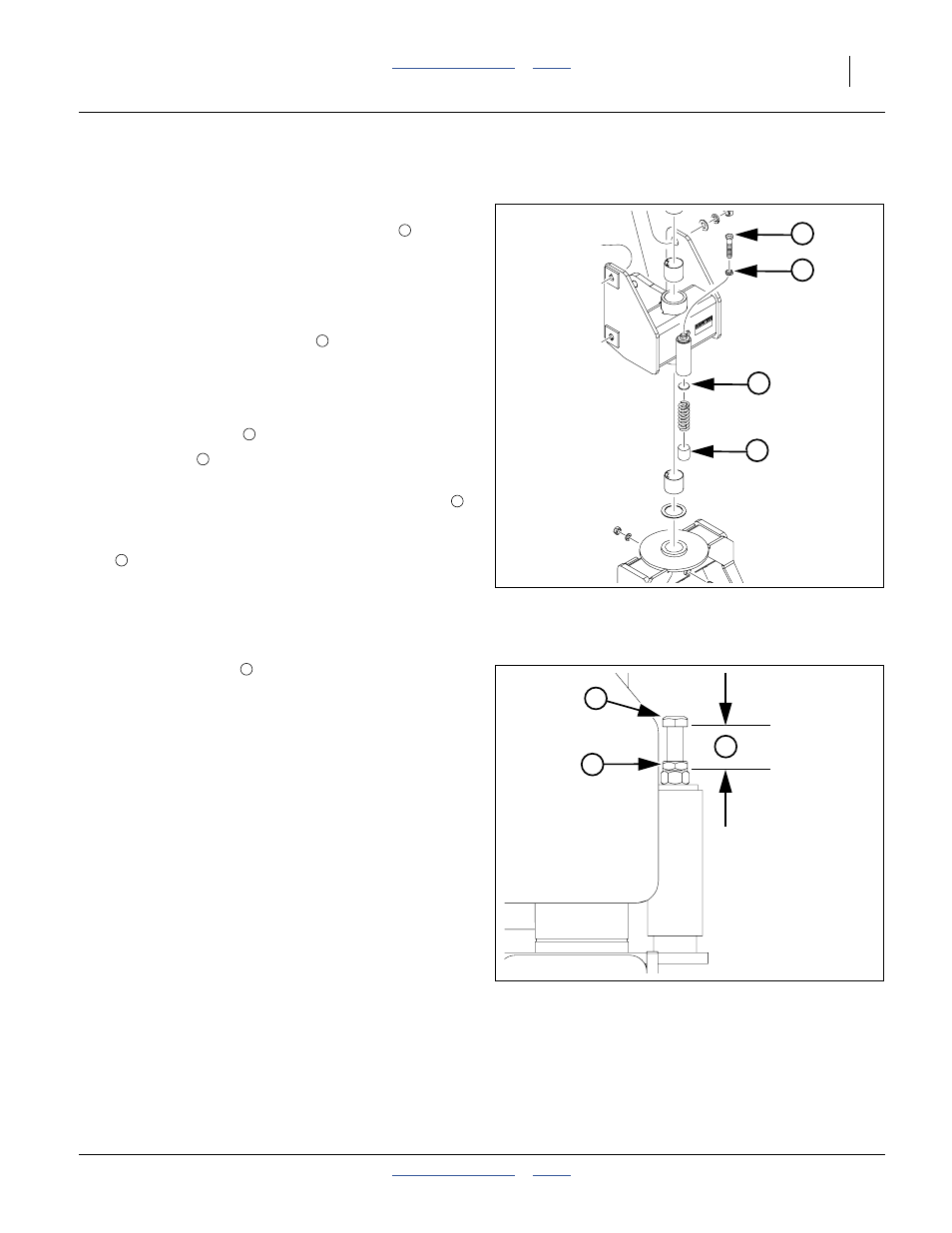

Caster Brake Adjustment

Refer to Figure 95

The rear lift-assist wheels each have independent

adjusters for the caster pivot brake. The piston

acts as

a pivot brake, and helps prevent caster oscillation during

transport. The adjustments will vary depending on

different field-to-field conditions as well as road transport

conditions.

If the caster is oscillating during transport turns or in field

use, adjust the pressure plate bolt

.

Pressure Plate Adjustment

Refer to Figure 95 and Figure 96

The factory setting for a new piston is:

1.

Loosen the jam nut

2.

Turn the bolt

counterclockwise until the bolt is

turning freely.

3.

Drive screw in (down) until it contacts spring plate

.

4.

Drive screw in until the bolt reveal (from top of

welded nut to bottom of bolt head) is:

2.0 inches (5.1 cm)

5.

Tighten the jam nut.

Use more or less tension as needed to eliminate caster

vibration during highway transport. Adjust as needed to

compensate for piston wear.

Replace UHMW piston

1

1

⁄

4

in. (3.2 cm). Also replace piston if missing,

damaged, tilted, or top of piston is visible.

1

3

4

5

Figure 95

Caster Brake Components

32319

5

3

5

2

Figure 96

Rear Caster Adjustment Bolt

34955

5

2