Maintenance and lubrication, Maintenance, Maintenance and lubrication maintenance – Great Plains NP30A 30-foot Operator Manual User Manual

Page 111

2014-05-20

407-502M

Great Plains Manufacturing, Inc.

107

Maintenance and Lubrication

Maintenance

Proper servicing and maintenance is the key to long

applicator life. With careful and systematic inspection,

you can avoid costly maintenance, downtime, and repair.

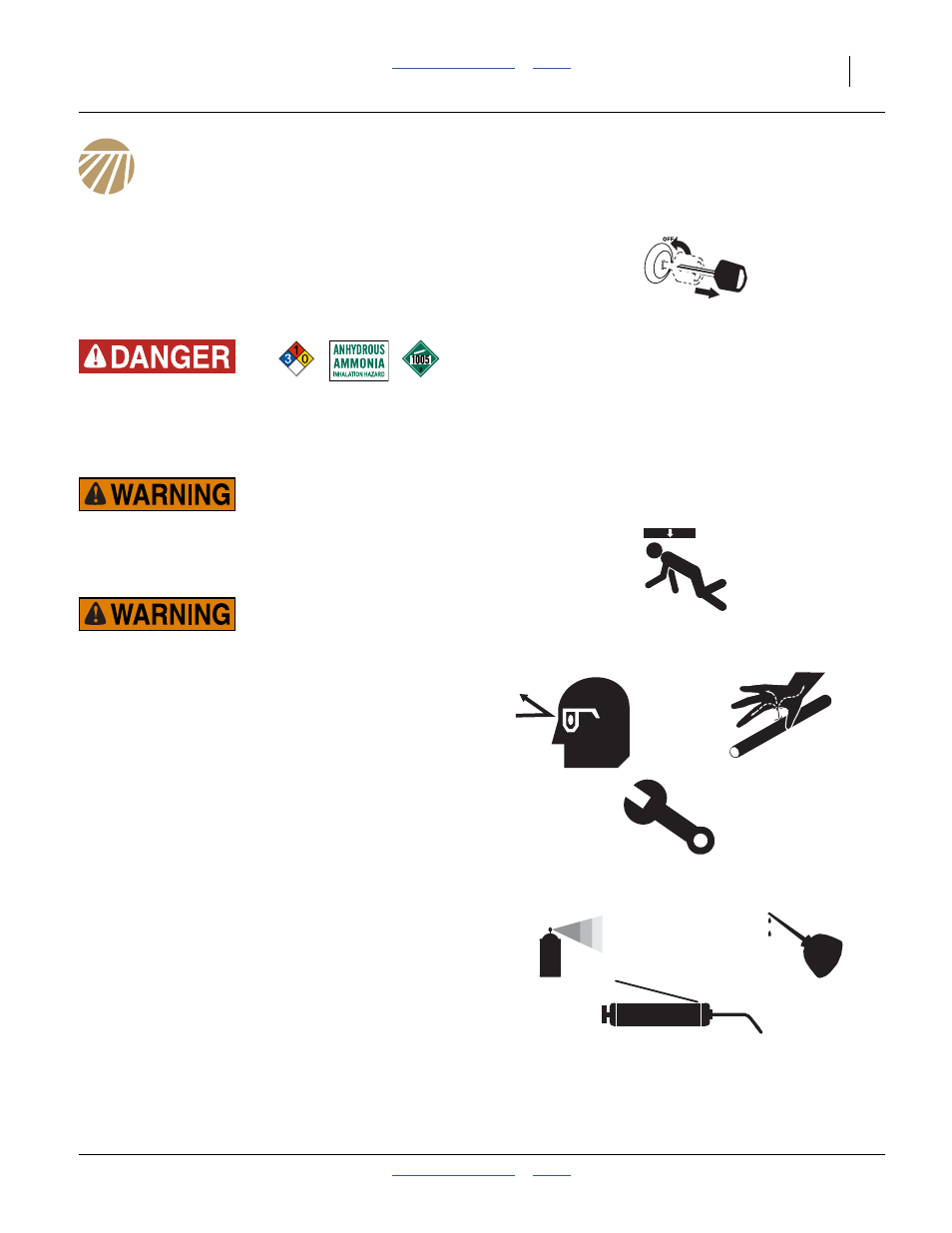

Always turn off and remove the tractor key before making

any adjustments or performing any maintenance.

Suffocation, Blinding, Burning, Freezing, Disabling and

Disfigurement Hazards:

Do not perform maintenance with anhydrous ammonia in the

system. Fully discharge the system of NH

3

liquid and vapor

before working on the applicator. See page 110.

Crushing Hazard:

Always have transport locks and/or parking stands in place

when working on applicator. You may be severely injured or

killed by being crushed under a falling applicator.

High Pressure Fluid Hazard:

Check all hydraulic lines and fittings before applying pressure.

Fluid escaping from a very small hole can be almost invisible.

Use paper or cardboard, not body parts, and wear heavy

gloves to check for suspected leaks. Escaping fluid under

pressure can have sufficient pressure to penetrate the skin. If

an accident occurs, seek immediate medical assistance from a

physician familiar with this type of injury.

1.

After using your fertilizer applicator for several hours,

check all bolts to be sure they are tight.

2.

Remove excess slack from chains. Clean and use

chain lube on all roller chains as needed.

3.

Maintain proper air pressure in fertilizer applicator

tires.

4.

Clean fertilizer applicator on a regular basis. Regular

and thorough cleaning will lengthen equipment life

and reduce maintenance and repair.

5.

Lubricate areas listed under “Lubrication and

Scheduled Maintenance” on page 126.

6.

Replace any worn, damaged, or illegible safety

labels by obtaining new labels from your Great

Plains dealer.