Material clean-out, Air box clean-out, Air system clean-out – Great Plains YP3025A Operator Manual User Manual

Page 99: Air box clean-out air system clean-out

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

95

02/16/2012

401-705M

Material Clean-Out

When planting is completed, it is commonly the case that

some seed remains. There may be seed in the hopper or

bulk box, seed in the airbox, a small amount of seed in

the hose lines, and seed in the meters. Some meters

may be filled up to the air release vent (which prevents

additional seed from reaching that meter).

A complete system clean-out is a 3 step process.

A. Empty airbox (and hopper, if desired).

B. Blow residual seed to meters.

C. Clean out meters with fan running.

Possible Dust and Chemical Fume Hazard:

Wear a respirator, and any other protective equipment speci-

fied by the seed and/or seed treatment supplier. Expect dust

and fumes during hopper clean-out.

Air Box Clean-Out

1.

Place a tarp or large container under the air box

clean-out doors.

Close the slide gates

on the hopper or bulk box.

3.

Open air box clean-out doors.

4.

If hoppers are mounted, gradually open hopper slide

gates. Leave bulk seed box gates closed, unless the

boxes actually need to be emptied.

Use gates to regulate seed flow while recovering

seed.

5.

As flow subsides, rapidly open and close the slide

gate to dislodge seed in the tracks. Tap on the sides

of the hopper to dislodge residual seed.

Air System Clean-Out

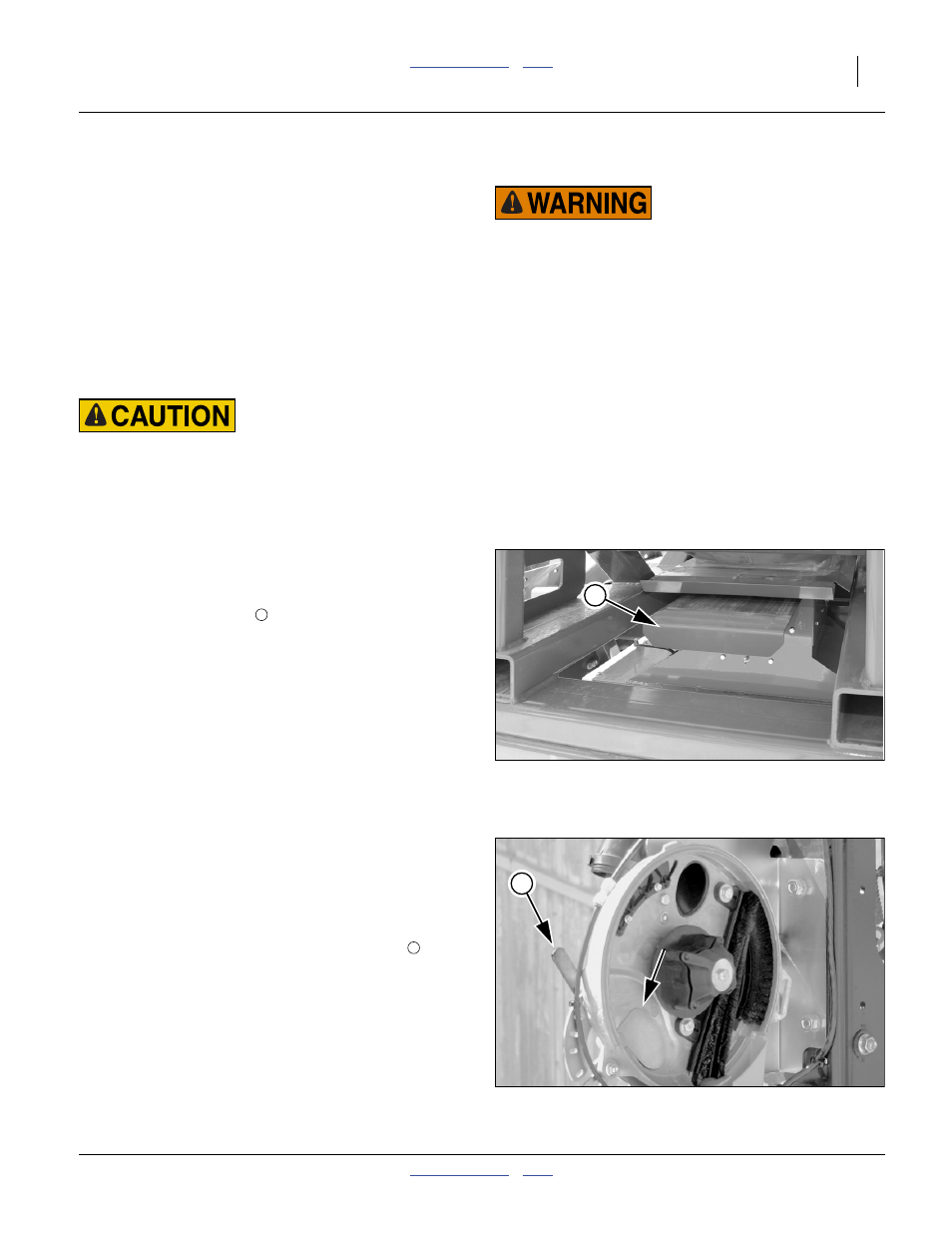

Refer to Figure 108 (which also depicts the meter with the rain

cover and disk removed - do not remove disk until step 14)

6.

Close slide gates.

Close air box clean-out doors.

7.

Set all seed inlet shutters to closed (handle

raised to the position above setting “I”).

This step prevents meter pressurization air from

leaking back against seed delivery air at meters that

have low seed pools or are empty.

Entrapment and Rapid Suffocation Hazard:

Never enter a hopper for any reason.

Keep strainer in place at all times.

▲ A hopper that is full or merely appears full can be an

entrapment hazard. You can sink entirely into the grain, or

into an oxygen-deficient void, and suffocate in a matter of

seconds. Grain bridges and crusts are especially danger-

ous.

▲ When hazardous fumes are present, you can be quickly

overcome even with the hopper lid open.

▲ Do not enter a hopper for material loading, material

unloading, hopper cleaning or meter maintenance.

▲ Clean hopper by power washing from outside hopper top.

1

Null4:

Figure 107

Hopper Slide Gate Open

29495

2

Null4:

Figure 108

Seed Inlet Shutter Closed

29609

2