Operating instructions, Pre-start checklist, Fold/unfold lock overview – Great Plains YP3025A Operator Manual User Manual

Page 28

401-705M

02/16/2012

24

YP3025A

Great Plains Manufacturing, Inc.

Operating Instructions

This section covers general operating procedures. Expe-

rience, machine familiarity, and the following information

will lead to efficient operation and good working habits.

Always operate farm machinery with safety in mind.

Pre-Start Checklist

Perform the following steps before transporting the

YP3025A planter to the field.

❑ Carefully read “Important Safety Information” on

❑ Install seed disks appropriate for crop. See

“Air-Pro® Meter Disk Installation” on page 76.

❑ Lubricate planter as indicated under “Lubrication

and Scheduled Maintenance” on page 113.

❑ Check all tires for proper inflation. See “Tire Infla-

❑ Check all bolts, pins, and fasteners. Torque as

shown in “Torque Values Chart” on page 140.

❑ Check planter for worn or damaged parts. Repair or

replace parts before going to the field.

❑ Check hydraulic hoses, fittings, and cylinders for

leaks. Repair or replace before going to the field.

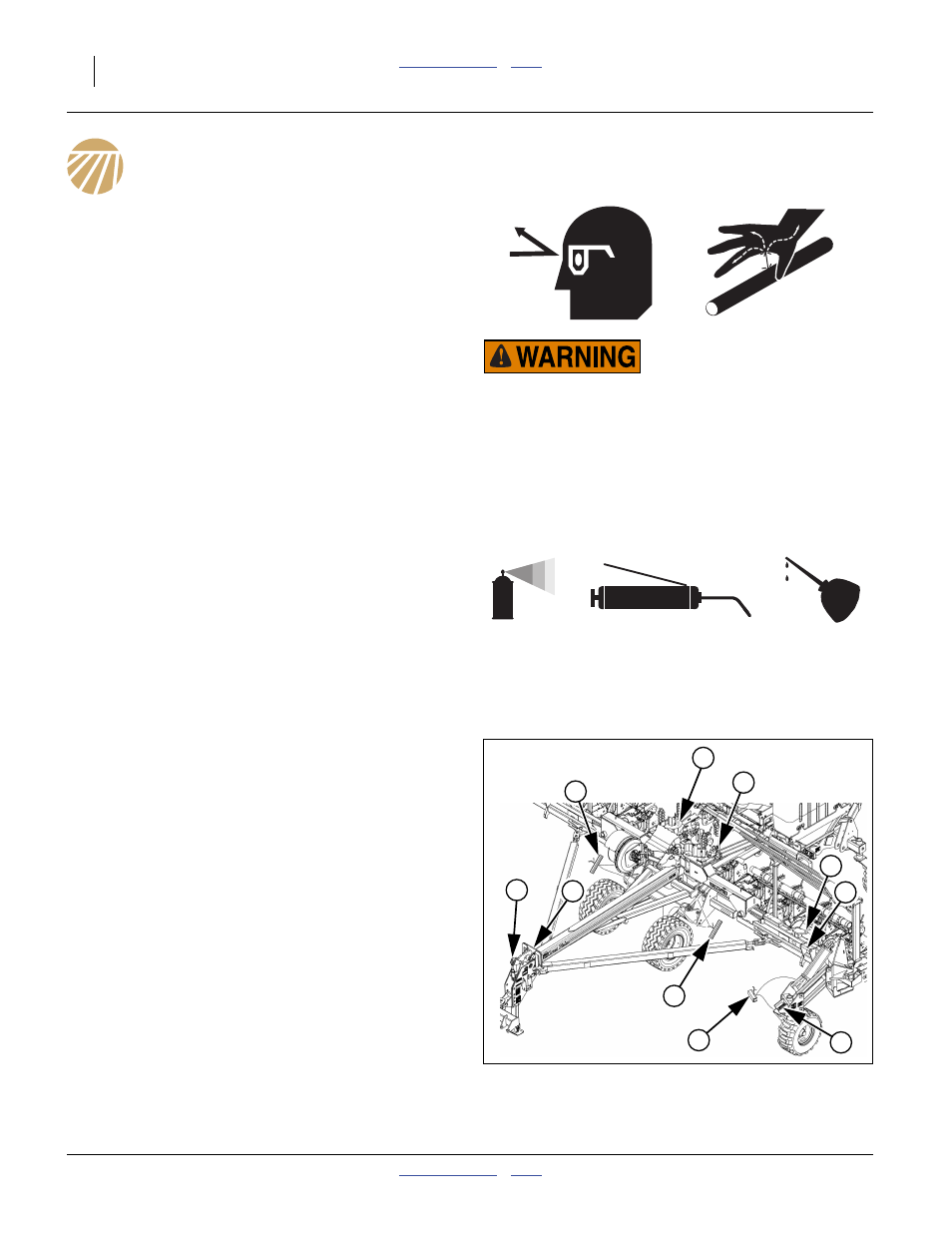

Fold/Unfold Lock Overview

The YP3025A planter includes five sets of locks for the

frame, wings and casters:

Wing locks: Hooks on the tongue engage locks on

the wings to prevent unfolding in transport. Tongue

must be raised to engage/release. See page 26.

2.

Lift cylinder lock channels: These are operator-

installed on a raised plater, these prevent lowering in

transport or when parked. See page 29.

3.

Fold cylinder and Caster swing arm cylinder lock

valves: Automatic switch-controlled solenoid valves

prevent motion of the fold cylinders and caster swing

arm cylinders, in transport and field. See page 142.

4.

Tongue lock: This engages automatically at unfold,

and lock the tongue/draw bar geometry for field oper-

ations. See page 26.

5.

Caster pivot locks: operator-engaged after unfold,

these prevent caster swiveling in the field, which aids

in tracking across hillsides. See page 31.

High Pressure Fluid Hazard:

Relieve pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. Escaping fluid under

pressure can have sufficient pressure to penetrate the skin

causing serious injury. If an accident occurs, seek immediate

medical assistance from a physician familiar with this type of

injury.

Null4:

Figure 15

Fold/Unfold/Lift Locking Features

31542