Optimal seed pool slopes, Meter re-fill, Optimal seed pool slopes meter re-fill – Great Plains YP3025A Operator Manual User Manual

Page 79

Great Plains Manufacturing, Inc.

Adjustments

75

02/16/2012

401-705M

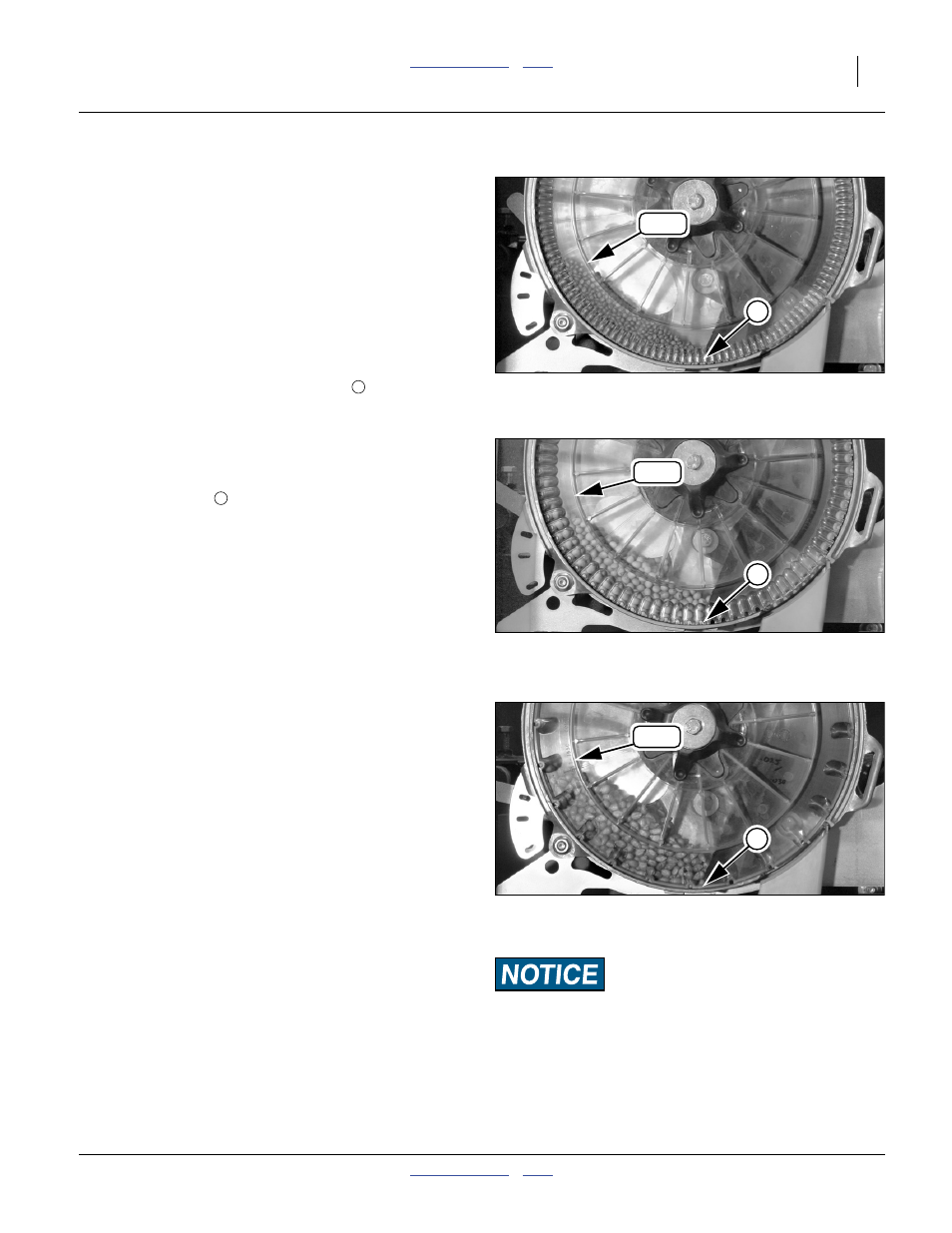

Optimal Seed Pool Slopes

The optimal seed slope is one that results in the most

consistent seeding, with minimal skips and doubles. The

column at right has photographs of pool slopes found to

be optimal for representative seeds.

If the suggested initial shutter settings do not seem to be

working for your seed, adjust the shutter to achieve spe-

cific reserve slope targets.

Refer to Figure 88

For medium size and smaller seeds that flow easily, the

slope runs from just above the 8:00 (o’clock) position on

the housing wall, forward and down to one or two seeds

deep at the base of the rear strip brush

.

Refer to Figure 89 and Figure 90

For medium size and larger, or heavily treated smaller

seeds that flow less easily, the slope runs from at or

slightly above the 8:30 (o’clock) position on the housing

wall, forward and down to 3-6 seeds deep at the base of

the rear strip brush

In general, the seeds at the base of the strip brush need

to be deep enough that no air escapes there, and so that

just enough seeds are present to begin populating cells.

Keep the top left/rear end of the pool below the 9:00

o’clock position (meter horizontal center-line).

Meter Re-Fill

Once planting is underway with the seed pools set, it is

infrequently possible for bridging at or above the inlet to

starve the meter of seed.

An empty meter causes seed monitor “Row Failure”

alarm, with a report of the row number. Row numbers are

counted from the left wing (outside row is row 1).

Stop, and put the tractor in Park. Leave the fan running.

Locate the failed row, remove the rain cover, and verify

that the meter is empty. Note the shutter setting. Tempo-

rarily open the shutter one of two notches wider. if the

problem was inlet bridging, seed should flow into the

meter immediately.

If inlet bridging is not the problem, little or no seed flows

into the meter with the shutter open wider. In this case,

the problem is further upstream in the seed flow, and

may be bridging at the air release screen at the top of the

meter. Close the shutter completely for about 15 sec-

onds. This prevents meter pressurization air from oppos-

ing seed delivery air. The delivery air pressure usually

collapses the bridge. Re-open the shutter and see if

seed now fills the meter.

If no obvious foreign object was the cause of the bridg-

ing, the shutter setting may have been too small for the

seed. Verify that this and other operating rows were at

the correct initial shutter setting. If so, re-set the shutters

to the next higher opening.

Metadata: End of “Seed Inlet Shutter Adjustment”

Null4:

Figure 88

Milo: Seed Inlet Shutter at: 1

29602

1

8:00

1

Null4:

Figure 89

Soybeans: Seed Inlet Shutter at: 2

29604

8:30

Null4:

Foreign Object Risk:

After clearing a bridge, or a delivery blockage upstream, check

the seed pool at the meter for any debris that might have been

the original cause. Remove such debris from the meter before

planting. Don’t run the risk of an object lodging in a seed

pocket and causing on-going skips.

Figure 90

Corn: Seed Inlet Shutter at: 3

29603

8:30