25ap series row unit adjustments – Great Plains YP3025A Operator Manual User Manual

Page 69

Great Plains Manufacturing, Inc.

Adjustments

65

02/16/2012

401-705M

25AP Series Row Unit Adjustments

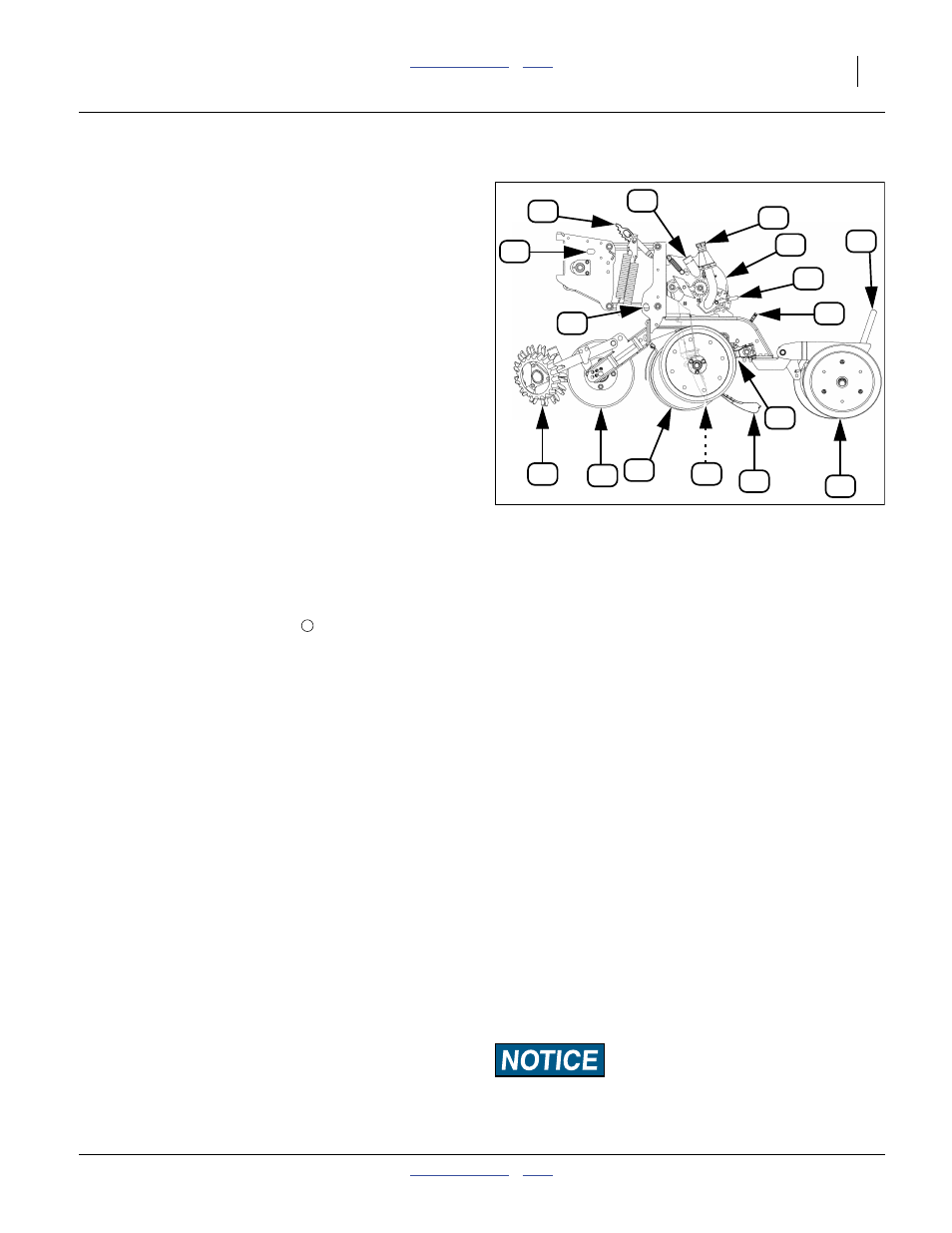

Refer to Figure 65 (which depicts a row unit populated

with most optional accessories supported for use with

the YP3025A Planter)

From front to back, a Great Plains 25 Series row unit can

include the following capabilities (some optional):

1.

Lock-Up Pin Storage Hole (Hole Standard)

See “Row Unit Shut-Off” on page 78.

2.

Down-Pressure Cam (Standard)

Row units are mounted on parallel arms. This paral-

lel-action mounting allows the row-unit to move up

and down while staying horizontal. Springs add an

adjustable force, set by the cam, to the row

weight.If the planter has the Row-Pro™ option, a

pneumatic cylinder controls row down-force by

counter-acting the springs under computer control.

See “Row Unit Down Pressure” on page 66.

3.

Air Inlet (Standard)

Pressure-regulated air enters the meter here and

holds seed in the disk pockets. See “Fan and

Adjustment” on page 61.

4.

Seed Delivery Hose Inlet (Standard)

Air carrying the bulk seed is vented at the bottom of

the air release cone. Gravity then carries the seed

into the meter at the shutter

removed for inspection. There are no adjustments.

5.

Air-Pro

®

Seed Meter (Standard, Choice of Disks)

See “Air-Pro® Meter Disk Installation” on page 76.

6.

Seed Inlet Shutter (Standard)

This controls the level of bulk seed at the disk. There

are four operating settings, plus fully open (clean-

out) and fully closed (shut-off or storage). See “Seed

Inlet Shutter Adjustment” on page 74.

7.

Side Gauge Wheel Depth (Standard)

The T-handle sets planting depth by controlling the

height of the side gauge wheels relative to the

opener discs. See “Setting Planting Depth” on

page 71.

8.

Press Wheel Force, Angle, Stagger (Standard)

The press wheels close the furrow, gently pressing

the soil over the seed to ensure good seed to soil

contact for even emergence. See “Press Wheel

Adjustment” on page 81.

9.

Row Unit Lock-Up Hole (Hole Standard)

Pins are standard on some models. With the row unit

raised above level, the lock-up pin is inserted here.

See “Row Unit Shut-Off” on page 78.

10. Row Cleaner (Option)

Row cleaners clear trash from the row, to a depth set

by an adjustment on the arms. See “Unit-Mount

Cleaner Adjustments” on page 68.

11. Unit-Mount Coulter (Option)

Coulters cut remaining trash and begin opening the

seed furrow. Working depth is set by row depth and a

mounting hole selection. See “Coulter Adjust-

ments” on page 69.

12. Opener Discs (Standard)

Row-unit double disc openers create the seedbed

furrow. They have adjustments for angle and spac-

ing. See “Row-Unit Opener Disk Adjustments” on

page 71.

13. Seed Tube with Sensor (Standard)

Requires no adjustment.

14. Scrapers (Optional, not shown)

Inside scrapers require no adjustment. For gauge

wheel scrapers, see “Adjusting Gauge Wheel

Scrapers” on page 73.

15. Seed Firmers (Seed Flap Standard, not shown)

An optional seed firmer (Keeton shown) minimizes

seed bounce and improves soil contact. It may also

deliver fertilizer. See “Seed Firmer Adjustments”

on page 80.

16. Press Wheel Type (Choice)

A variety of single and dual press wheel assemblies

are available, some region-specific. Consult your

Great Plains dealer.

Do not back up with row units in the ground. To do so will

cause severe damage and row unit plugging.

Null4:

Figure 65

25 Series Row Unit

29600

6