Seed disk maintenance, Cleaning and storing seed disks – Great Plains YP3025A Operator Manual User Manual

Page 104

100

YP3025A

Great Plains Manufacturing, Inc.

401-705M

02/16/2012

Seed Disk Maintenance

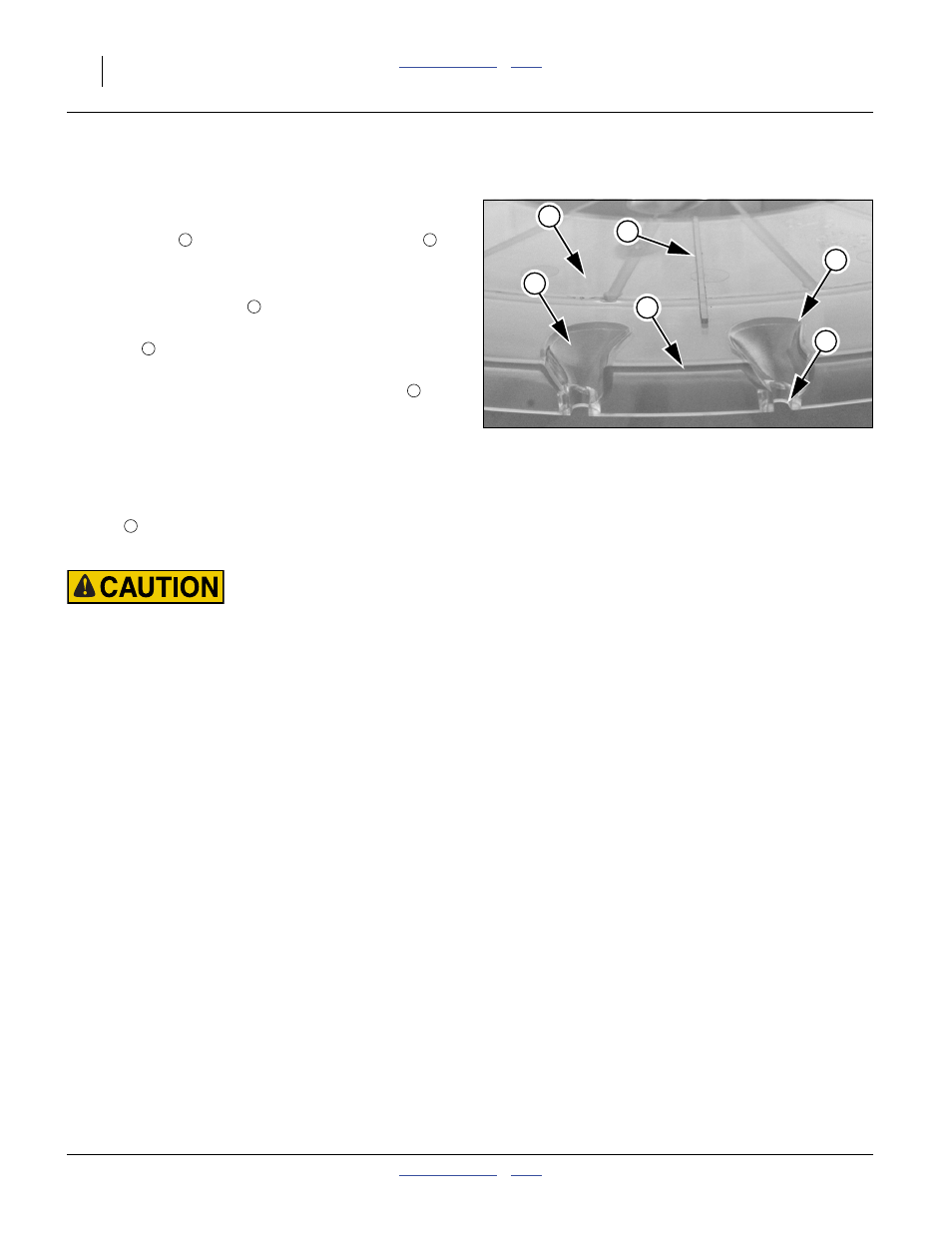

Refer to Figure 116

When removing seed disks, inspect them for wear and

damage. If there is any seed dust or treatment build-up in

the cell pockets

, or along the raised wiper ridges

clean the disks and re-inspect.

Replace disks for conditions including:

• Chips at circumference

• Chips at edges or in sculpted surfaces of cell

pockets

. These can leak air and/or adversely affect

singulation.

• Cracks over 2in (5cm) long in the working face

the disk, or any cracks in support webs or to an edge.

• Warping - if any part of the disk does not press firmly

on the seed drop brushes (page 76) in operation,

replace the disk.

• Wear - if a wiper ridge is worn away, replace the disk.

If the seed pockets are worn through, or the air

ports

have enlarged, replace the disk.

Cleaning and Storing Seed Disks

Possible Chemical Hazard:

Wear gloves when washing disks. Avoid spray. Do not wash

disks where food is prepared, or where cookware or dinner-

ware is washed. Seed disks will have talc and graphite residue,

and may have residues of hazardous seed treatments. Although

the disks are dishwasher-safe, do not wash them in an appli-

ance also used for food preparation or food serving items.

Use warm or hot water, mild soap, and a sponge or soft

brush to remove build-up.

If disks are washed, allow them to dry completely prior to

storage.

Retain original shipping cartons for disk storage. Other-

wise, store them on edge (and not leaning), or stacked

horizontally on a spindle, to eliminate any risk of warps.

Any seed residue on disks may attract pests. Fully

enclose dry disks to prevent rodent damage.

Metadata: End of “Meter Brush Maintenance”.

Null4:

Figure 116

Disk Seed Cells and Wiper

29613

2

1

4

5

3

2

4