Fertilizer system maintenance, Liquid fertilizer strainer, In season filter cleaning – Great Plains YP3025A Operator Manual User Manual

Page 116: End of season filter cleaning

112

YP3025A

Great Plains Manufacturing, Inc.

401-705M

02/16/2012

Fertilizer System Maintenance

With proper attention to maintenance, end of day clean-

out, end of season clean-out and winterization, you can

substantially increase the life and reliability of your fertil-

izer system. Protect the pump, clean the tanks, strainers,

lines and nozzles, and you can avoid costly and time-

consuming repairs at the next season.

Fertilizers are usually highly corrosive to metals other

than stainless steel. Suspension fertilizers can clog sys-

tem components in storage.

1.

Flush entire system with clean water.

2.

Remove end caps from booms and flush booms out

with water. Drain and replace end caps.

3.

Remove strainer and drain it out. Drain all lines and

tanks completely to prevent freezing damage.

4.

Flush pump per pump supplier manual. Fill pump

with RV antifreeze and cap off.

5.

Wash all spilled fertilizer off the planter.

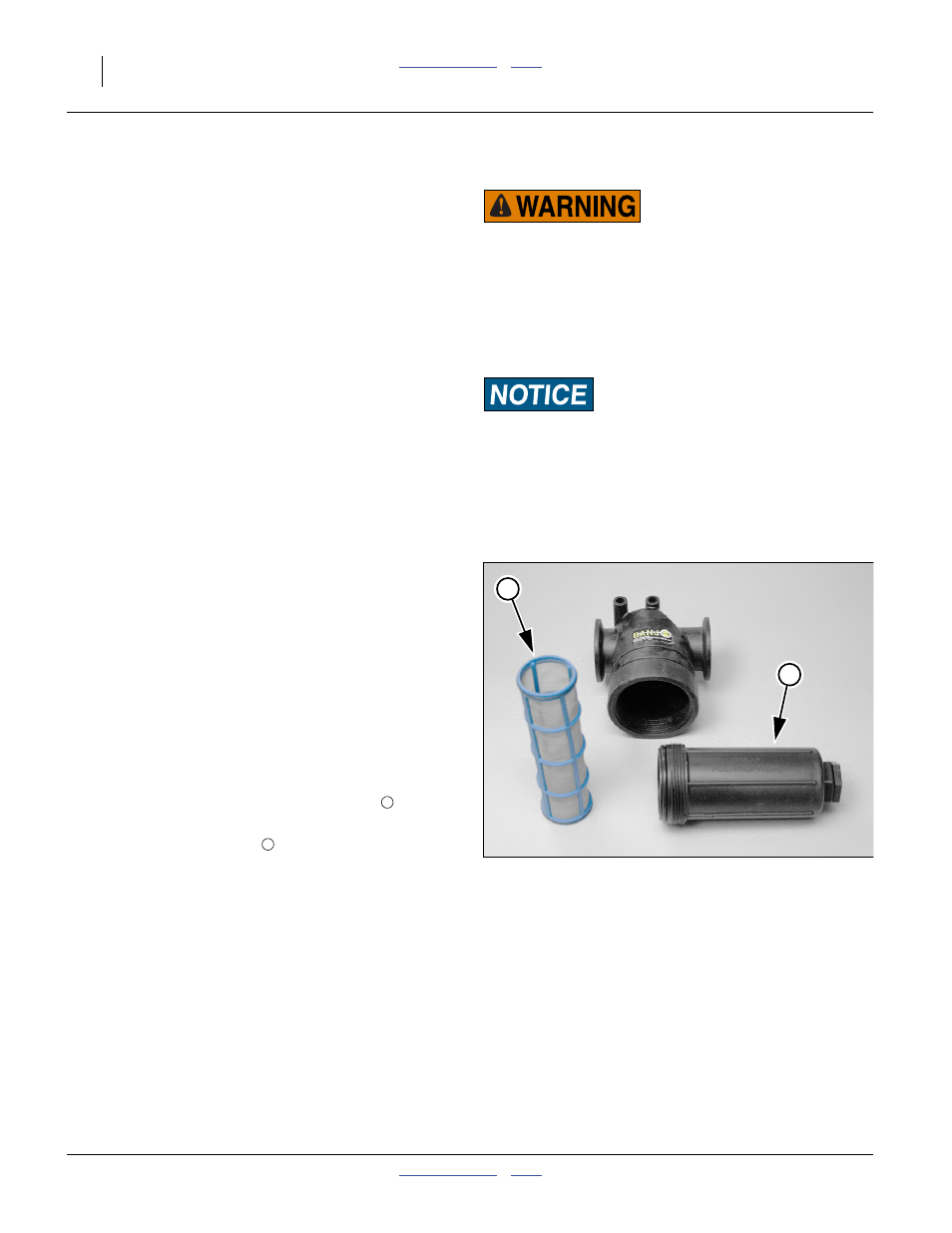

Liquid Fertilizer Strainer

Refer to Figure 137

The fertilizer system uses an in-line strainer to keep

damaging particulates out of the pump. The strainer

becomes clogged over time, reducing pump rate. Plan to

clean the strainer several times per season. Don’t wait

for application rates to fall below target. Higher quality

liquid fertilizers may require less frequent cleaning.

Disassemble and clean the strainer prior to storage to

prevent caking.

In Season Filter Cleaning

1.

Shut off the ball valve at the filter, to minimize prod-

uct spill.

2.

Unscrew and remove the bottom canister

of the fil-

ter.

3.

Wash the filter cartridge

with water, or replace with

new cartridge if necessary.

4.

Reinstall the cartridge, canister, and turn on the ball

valve.

Null4.aac:

End of Season Filter Cleaning

1.

Load 10 to 15 gallons (40 to 60 liters) of clean water

in each supply tank.

2.

Pump most of it through the system. If doing this by

hand-turning the ground drive wheel, first install the

largest drop-line orifice size, and set the pump

adjuster to maximum, to increase flow.

3.

With valves open, remove the canister. Clean

strainer and canister.

4.

Drain tanks and lines. Remove boom end-caps to

drain wings.

5.

Re-install strainer and canister.

6.

Add 2 pints (1 liter) of RV antifreeze to each tank.

Pump until tank is just empty (which leaves some

fluid in strainer).

7.

Open supply line above pump inlet. Introduce RV

antifreeze, and operate pump until pump is filled.

MetaData: End of

Possible Chemical Hazard:

Wear proper protective equipment as required by chemical

manufacturer. Avoid prolonged breathing of chemical fumes.

Wear respirator as required by chemical manufacturer. Some

chemicals will cause serious burns, lung damage, and death.

Avoid contact with skin or eyes. Seek medical assistance imme-

diately if accident occurs. Know what to do in case of an acci-

dent.

Equipment Damage Risk:

Do not leave fertilizer or fertilizer residue in pump. Do not

allow air to enter pump. Even for short periods of storage, the

entrance of air into the pump causes RAPID and SEVERE

CORROSION.

Null4:

Figure 137

In-line Filter

31322

1

2