Install press wheels, Install upper marker components – Great Plains YP3025A Operator Manual User Manual

Page 167

Great Plains Manufacturing, Inc.

Appendix B - Pre-Delivery

163

02/16/2012

401-705M

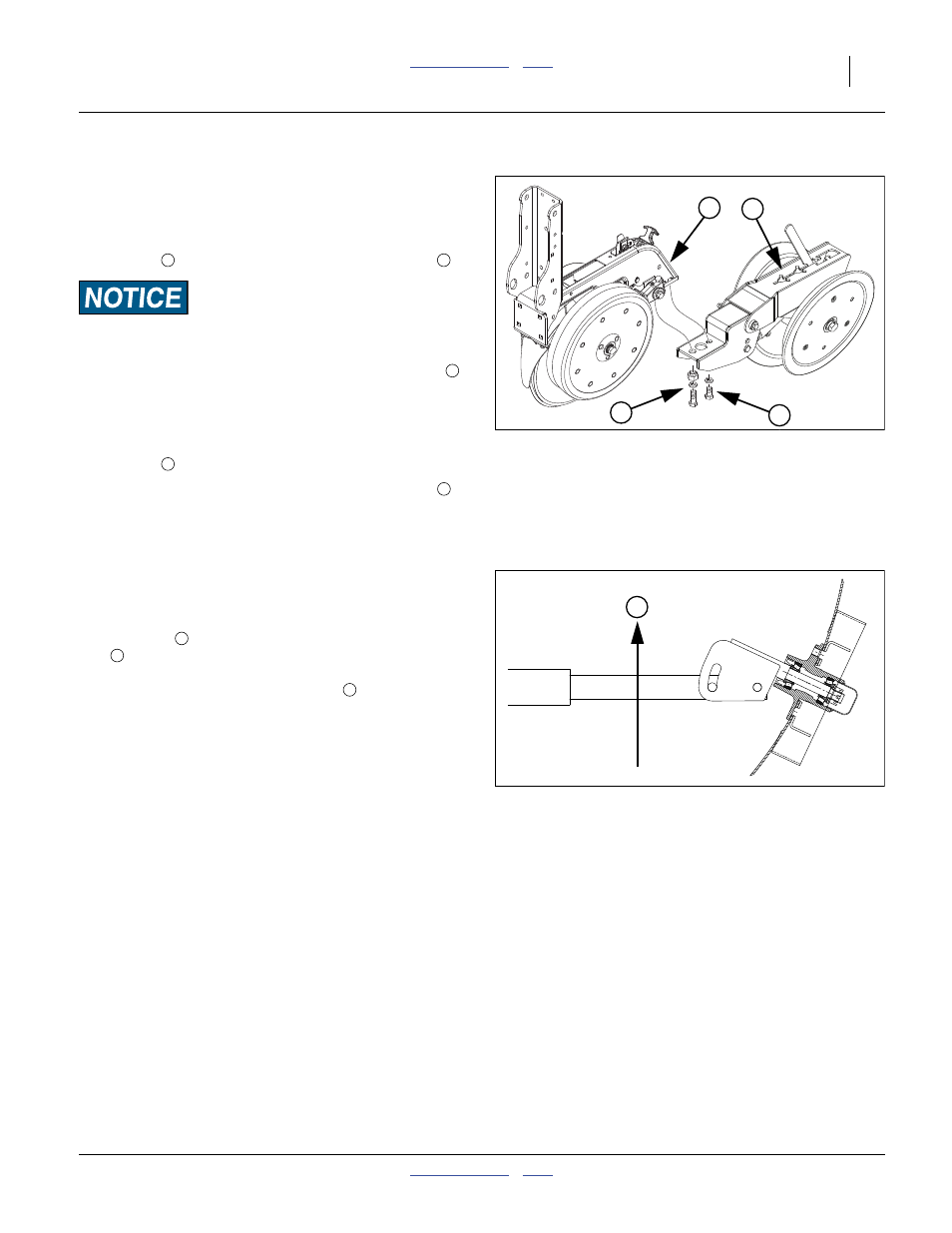

Install Press Wheels

To meet highway clearance requirements, press wheel

arms and wheels on wing rows are not factory-installed.

Remove and save the

1

⁄

2

-13x1in hex head bolt and

washer

at the back of an incomplete row unit

There are four bolts at this location. Remove only the hex head

bolts. Do not loosen or remove the square head bolts forward.

2.

Remove and save the

1

⁄

2

-13x1

1

⁄

2

in hex head bolt

,

washer, and eccentric adjuster nut.

3.

Align the

1

⁄

2

in holes in the press wheel assembly

with the

1

⁄

2

-13 tapped holes in the row unit, loosely

assemble with the

1

⁄

2

-13x1in hex head bolt and

washer

.

4.

Loosely screw in the

1

⁄

2

-13x1

1

⁄

2

in hex head bolt

washer, and eccentric adjuster nut. Rotate the

adjuster to visually align the press wheel assembly

with the row unit, and tight the adjust and both bolts.

Install Upper Marker Components

Marker disks and end tubes are removed for shipping.

Refer to Figure 140

The end tube

may be inserted into the outer marker

arm

in any of four orientations. Great Plains recom-

mends that the spindle adjustment allow the disk to pivot

back, away from the direction of travel

.

If the markers are extended for this work, also set the ini-

tial marker extension based on the row spacing.

Null4:

Figure 139

25AP Press Wheel Assembly

25383

1

2

4

3

3

4

Null4:

Figure 140

Marker Disk Spindle Orientation

11757

T

T