Marker adjustments, Marker disk adjustment, Nw t – Great Plains YP3025A Operator Manual User Manual

Page 64

60

YP3025A

Great Plains Manufacturing, Inc.

401-705M

02/16/2012

Marker Adjustments

There are three adjustments and two maintenance items

for markers:

• Disk Angle (following)

Even if your row spacing rarely changes, you may

need to adjust disk angle for soil conditions and plant-

ing speed.

• Shear Bolt Replacement (Maintenance, page 104)

If a marker hangs up on an obstruction, a bolt at the

fold is designed to fail.

• Marker Cylinder Bleed (Maintenance, page 104)

If marker operation is irregular, check that system is

not contaminated with air.

• Marker Extension (Marker Extension, page 166)

Once set for a specific row spacing, this only needs

periodic checking to ensure the clamp is secure.

• Marker Speed (Dual Marker Speed Adjustment,

page 164). Once initially set by your dealer, this rarely

needs modification.

Marker Disk Adjustment

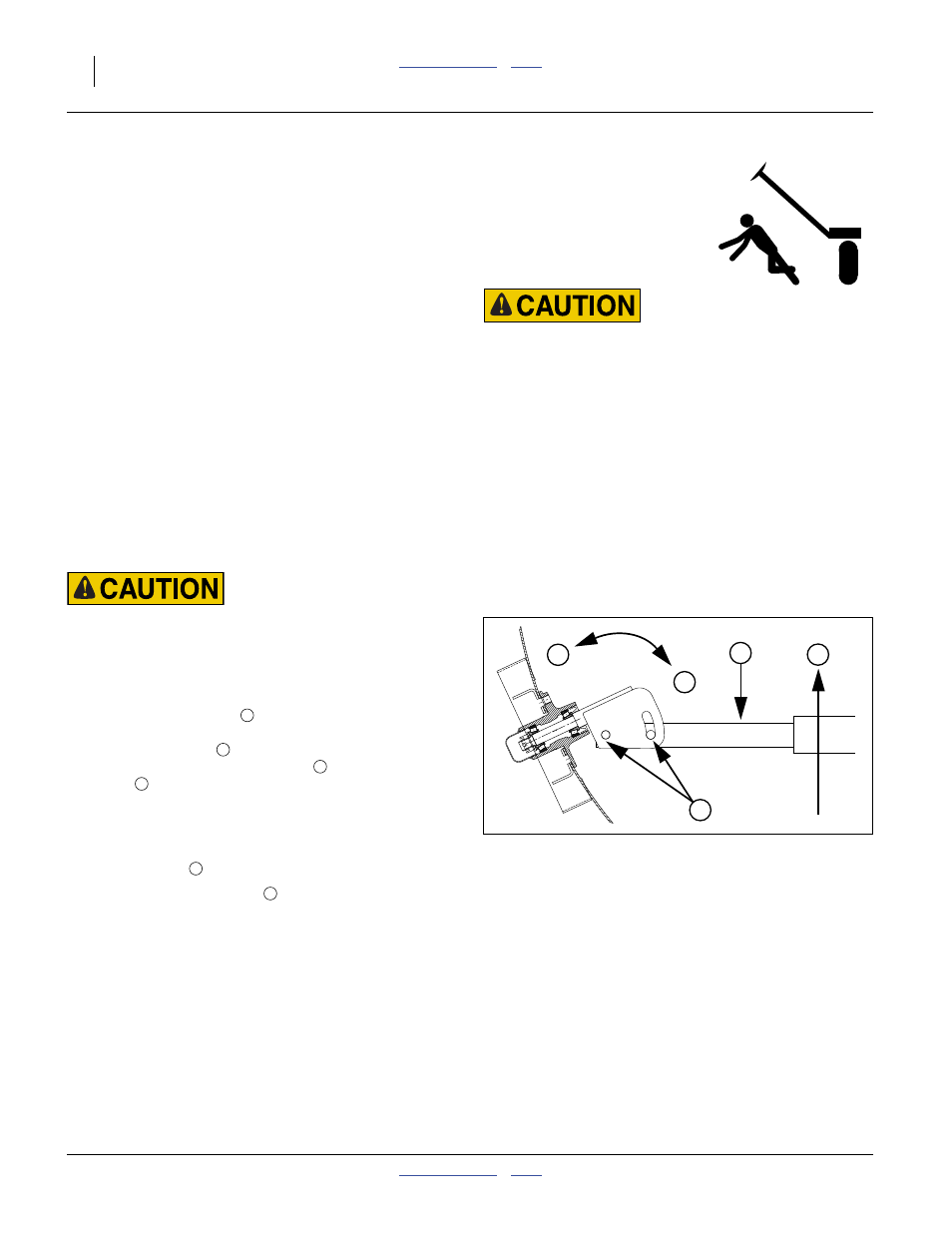

Sharp Object Hazard:

Use caution when making adjustments in this area. Marker

disks may be sharp.

To change angle of cut, and the width of the mark,

loosen

1

⁄

2

-inch bolts

holding the disk assembly.

For a wider mark

, increase the angle of the

marker with respect to the tube

. For a narrower

mark

, reduce the angle.

Note: Do not set a marker angle wider than need to make

a useful mark. Excess angle increases wear on all

marker components.

2.

Tighten bolts

Note: The direction of travel

tends to drive the disk an-

gle to Wide. If bolts are not tight enough, or loosen

over time, the disk will slip into the Wide mark con-

figuration.

Overhead Sudden Marker Movement Hazard:

You may be injured if hit by a folding or unfolding marker.

Markers may fall quickly and unexpectedly if the hydraulics

fail. Never allow anyone near the planter when folding or

unfolding the markers.

Null4:

Figure 63

Marker Disk Angle

11757

T

2

1

N

W

T

1