Great Plains YP1630F-1670 Operator Manual User Manual

Page 75

Great Plains Manufacturing, Inc.

Troubleshooting

71

2012-12-27

401-832M

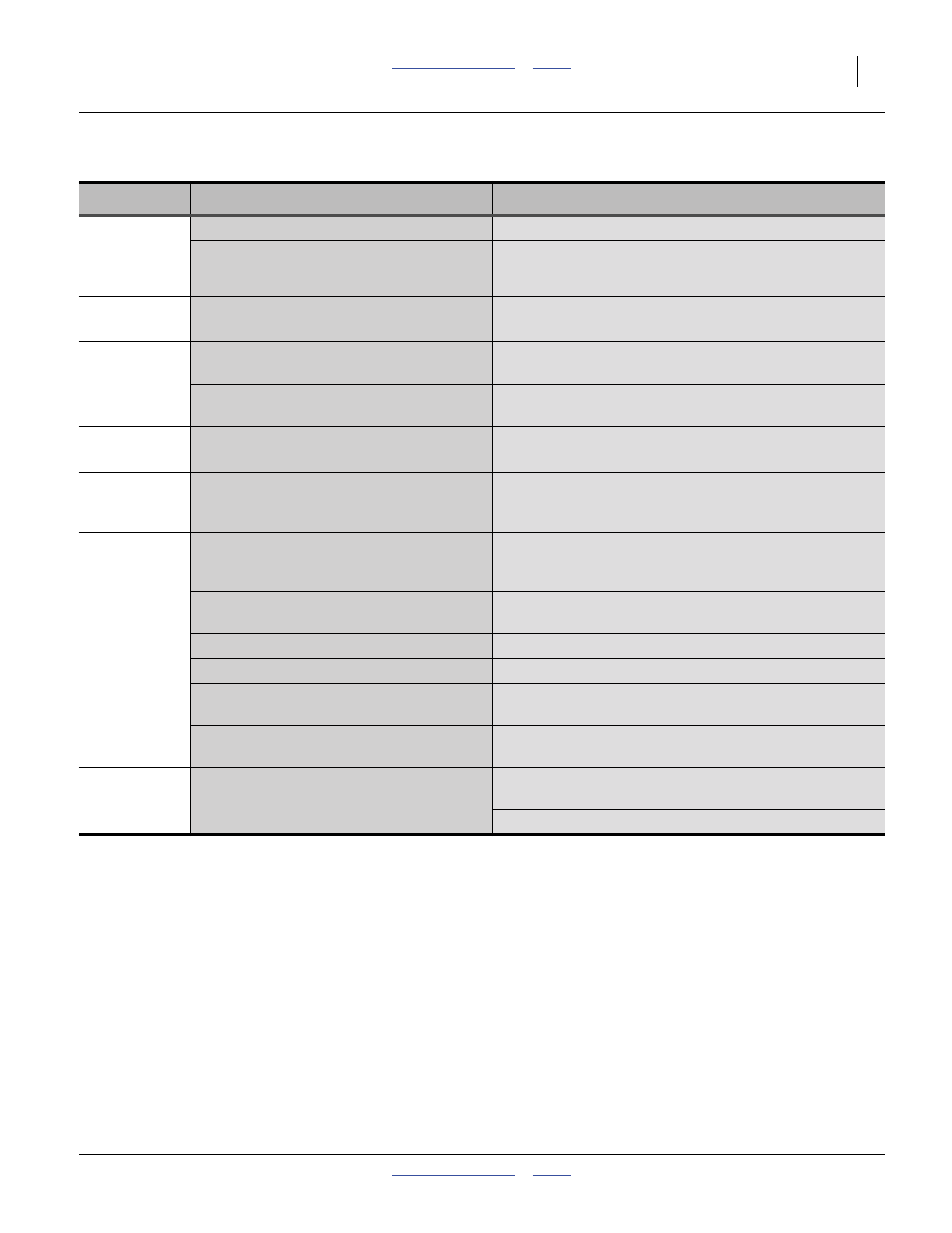

Air lines

plugging

between air

box and rows

Fan too slow.

Speed up fan.

Improper hose routing, sags or kinks

With planter unfolded, hoses should for a gentle “S”

shape through the holders, with no deep sags.

Planter will not

lower

Check that pressure and return hoses are

fully engaged in remote outlets.

Planter frame

raises or

lowers slowly

Lower tractor hydraulic pressure. Tractor operating

pressure must be a minimum of 10 340 kPa (1500 psi).

Operate tractor with flow control lever in the unrestricted

position. Refer to your tractor operator’s manual.

Erratic or

uneven lift

Check for air in hydraulic system. Bleed system of air if

necessary.

Planter will not

raise

Tractor hydraulic system bypassing oil. Readjust

tractor’s hydraulic lever linkage. Refer to your tractor

operator’s manual.

Hydraulic

marker

functioning

improperly, or

not at all

Marker/Fold switch set to FOLD or OFF.

Hydraulic Selector switch must be set to “Marker”. Set

tractor remote circuit to Neutral or Float before

operating switch.

Air or oil leaks in hose fittings or

connections.

Check all hose fittings and connections for air or oil

leaks.

Low tractor hydraulic oil level.

Check tractor hydraulic oil level.

Loose or missing bolts or fasteners.

Check all bolts and fasteners.

Needle valve plugged.

Open needle valve, cycle markers slowly and reset

needle valve, refer to page 49.

Needle valve(s) in sequence valve

plugged.

Open needle valves, cycle markers slowly and reset

needle valves, refer to page 49.

Marker disk

does not mark

Marker folding linkage does not have

enough slack to allow marker disk to drop

into field depressions.

Maximum down float should be limited by the slot at the

rod end of the marker cylinder, refer to page 49.

Reverse marker disk to pull or throw dirt.

General Troubleshooting

Problem

Cause

Solution