Monitor operation, Fan general operating information, Starting fan – Great Plains YP1630F-1670 Operator Manual User Manual

Page 46: Stopping fan, Starting fan stopping fan

42

YP1630F

Great Plains Manufacturing, Inc.

401-832M

2012-12-27

Monitor Operation

For monitor operation in the field, refer to the

DICKEY-john® PM400 Console Manual manual supplied

with this unit, and the Seed Rate manual.

Fan General Operating Information

Dry fertilizer metering rate is set by the variable rate gear

box; however, the fan must be set to provide sufficient

manifold pressure to deliver the metered material from

the airbox to the rows.

Starting Fan

Use tractor remote hydraulic valve flow control to set fan

speed. Always start the fan with a low flow setting.

Monitor fan output with the Magnehelic

®

pressure gauge.

Gradually bring fan up to the pressure recommended for

your rate. Normal readings are in the 15 inches to

30 inches of water (H

2

O) range, and vary with material

properties and application rate.

At excessive rpm, too much air flow can cause:

• fertilizer to plug the air box

• oil heating

• slow lift times

• fan motor damage, over 5000 rpm

If desired pressure cannot be reached, chances are the

fan is running backwards. Reverse the inlet/return lines

at the hitch.

If air system does not operate suitably at suggested

pressures, see “Fertilizer Delivery Troubleshooting”

on page 68.

Stopping Fan

Move circuit level to Neutral, or slowly reduce rate to

zero.

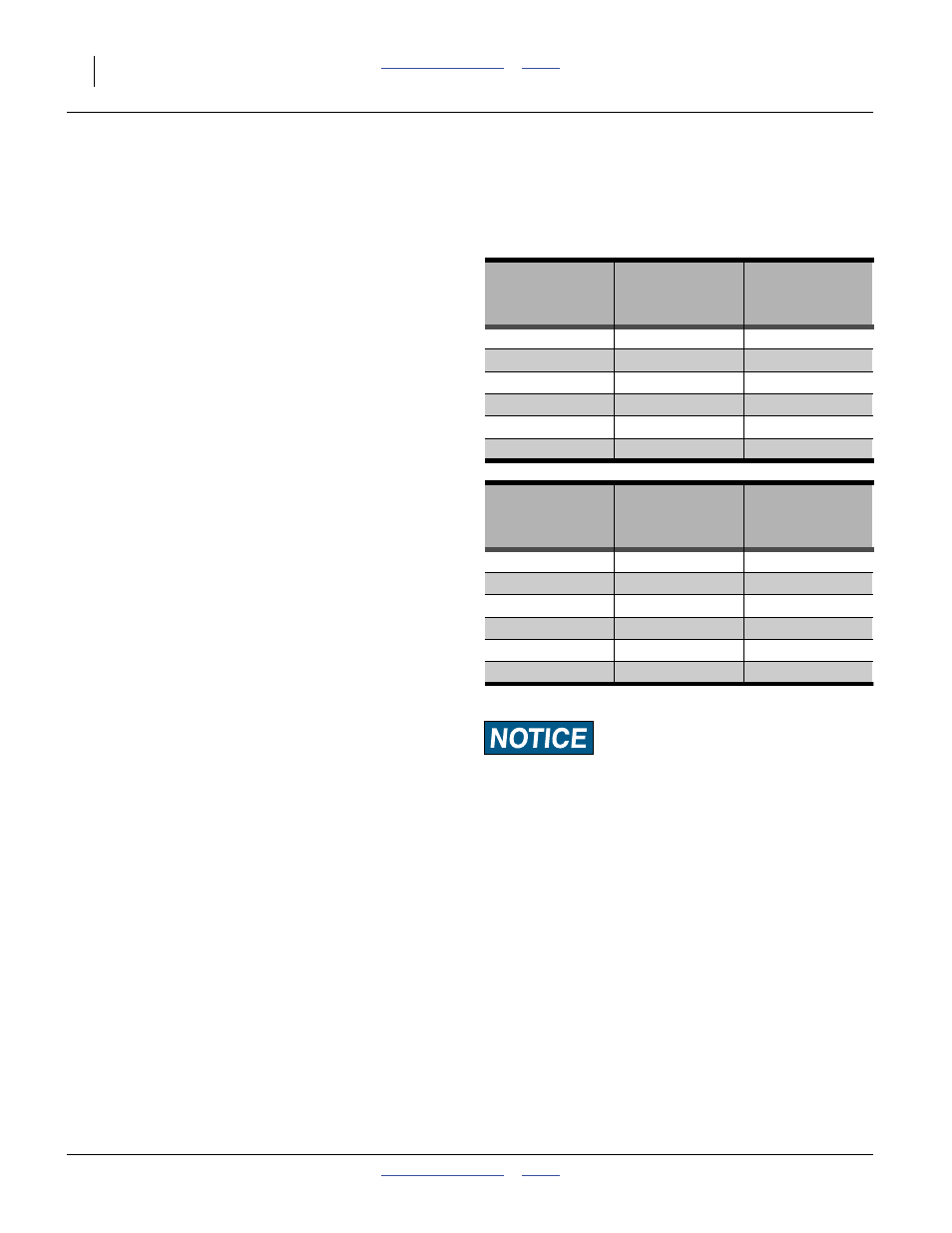

15.0

170

3500

15.8

200

3600

17.9

250

3800

20.4

300

4000

23.4

350

4300

26.6

400

4700

15.0

150

3500

16.7

200

3700

19.4

250

3900

22.5

300

4300

26.1

350

4600

30.0

400

5000

Manifold

Pressure

Inches H

2

O

Application

Rate

kg/ha

Approximate

Fan Speed

rpm

Manifold

Pressure

Inches H

2

O

Application

Rate

pounds/acre

Approximate

Fan Speed

rpm

Equipment Damage Risk:

Make only gradual changes to fan hydraulic flow (other than

shifting to Neutral). Fan impeller inertia and momentum can

cause pressure spikes in the motor in response to abrupt

changes. This can cause motor seal damage.

Do not operate fan above 5000 rpm (30 inches on gauge).