Row unit down pressure – Great Plains YP1630F-1670 Operator Manual User Manual

Page 56

52

YP1630F

Great Plains Manufacturing, Inc.

401-832M

2012-12-27

Row Unit Down Pressure

Row unit springs provide the primary control of down

pressure necessary for row unit disks to open a seed

trench. The springs allow the row units to float down into

depressions and up over obstructions. Springs also

provide down force on optional unit-mount coulters, and

provide the primary down force for press wheels.

Heavy-duty springs (page 105) are optional.

The total down pressure also includes the weight of the

empty row unit, and the weight of materials loaded. Use

half full hoppers when optimizing your settings.

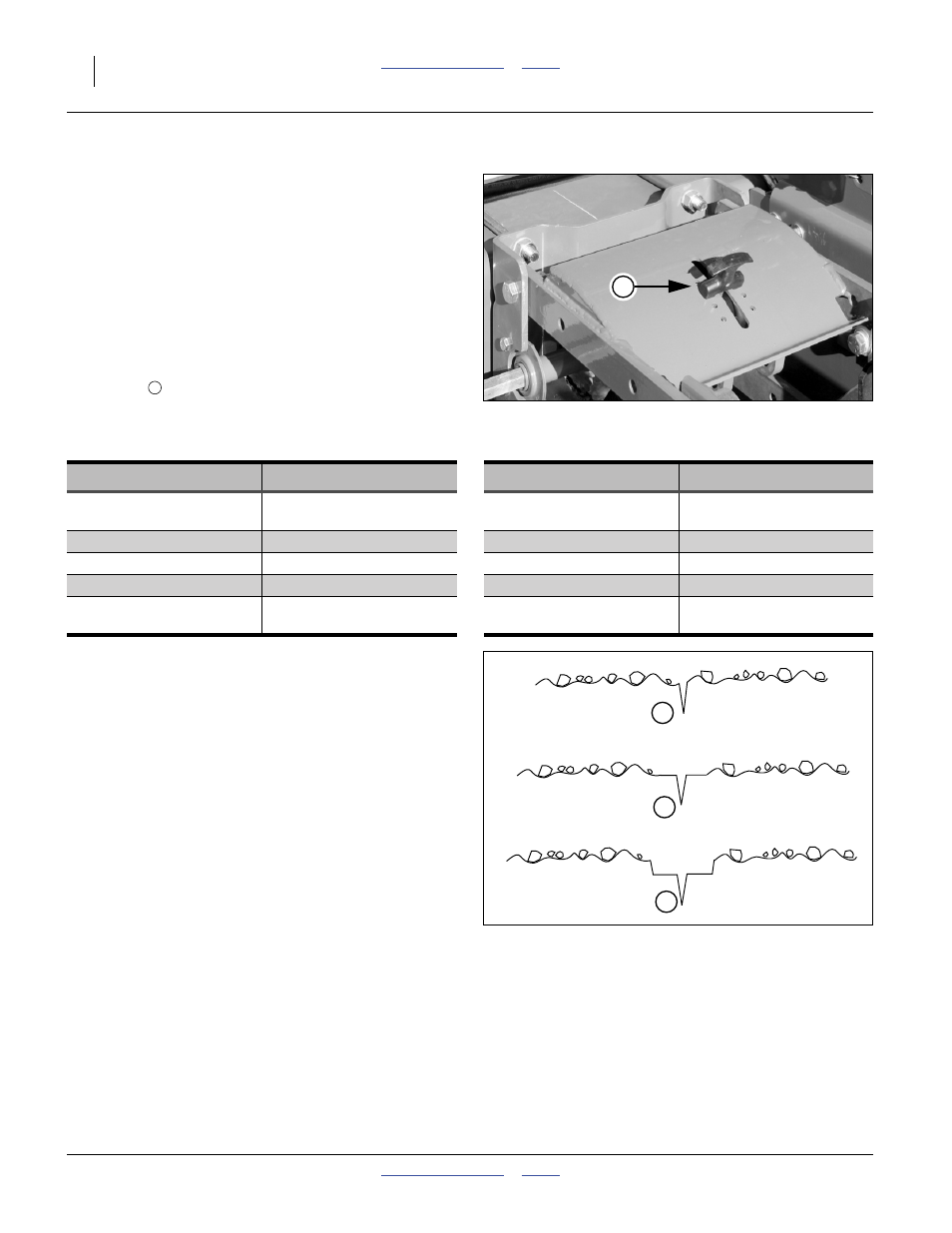

Refer to Figure 48

A T-handle

sets down pressure individually for each

row unit. This is useful for penetrating hard soil and

planting in tire tracks. For best results adjust tractor tires

so they are not ahead of rows.

Use only enough down pressure to cut the seed trench

and maintain proper soil-firming over seed. Excessive

row unit down force will lead to premature wear on row

unit components, uneven seed depth and gauge wheel

slippage.

The ideal amount of down-force causes the side gauge

wheels to compress any loose surface soil, but not press

a trench into subsoil.

To assess down-force, operate the planter for a short

distance on typical ground (with or without seeding), and

stop. Leave the planter lowered (row units in ground).

At several row units, inspect the furrow created by the

opener discs, but prior to furrow closing by the press

wheels.

Refer to Figure 49

1.

If the side gauge wheels are leaving no tracks, or

light tracks, increase down-force.

2.

If the wheels are compressing trash and loose soil,

and leaving clear tracks right at the top of the

subsoil, down-force is probably correct and needs no

adjustment.

3.

If the wheels are creating a trench into the subsoil,

down-force is too high and needs to be reduced.

Standard Springs

Spring Down Force

Heavy-Duty Springs

Spring Down Force

First Holes

(Closest to Tractor)

38 kg (85 pounds)

First Holes

(Closest to Tractor)

70 kg (155 pounds)

Second Holes

45 kg (100 pounds)

Second Holes

79 kg (175 pounds)

Third Holes

52 kg (115 pounds)

Third Holes

93 kg (205 pounds)

Fourth Holes

61 kg (135 pounds)

Fourth Holes

102 kg (225 pounds)

Fifth Holes

(Closest to Hopper)

70 kg (155 pounds)

Fifth Holes

(Closest to Hopper)

111 kg (245 pounds)

Figure 48

30 Series Down Force

25454

1

1

Light or no side gauge

wheel tracks

Insufficient down-force

Increase down-force

Gauge wheels compress

loose soil only

Ideal

No adjustment required

Side gauge wheels

making deep tracks

Down-force too high

Reduce down-force

Note: Do not set all rows higher than hole set four.

Using high settings across all rows causes uneven

planting. Individual rows may be set higher if

running in tire tracks.

Note: Inspect rows both in and out of tire tracks.

Figure 49: 30 Series:

Assessing Down-force