Field setup checklist – Great Plains YP1630F-1670 Operator Manual User Manual

Page 45

Great Plains Manufacturing, Inc.

Operating Instructions

41

2012-12-27

401-832M

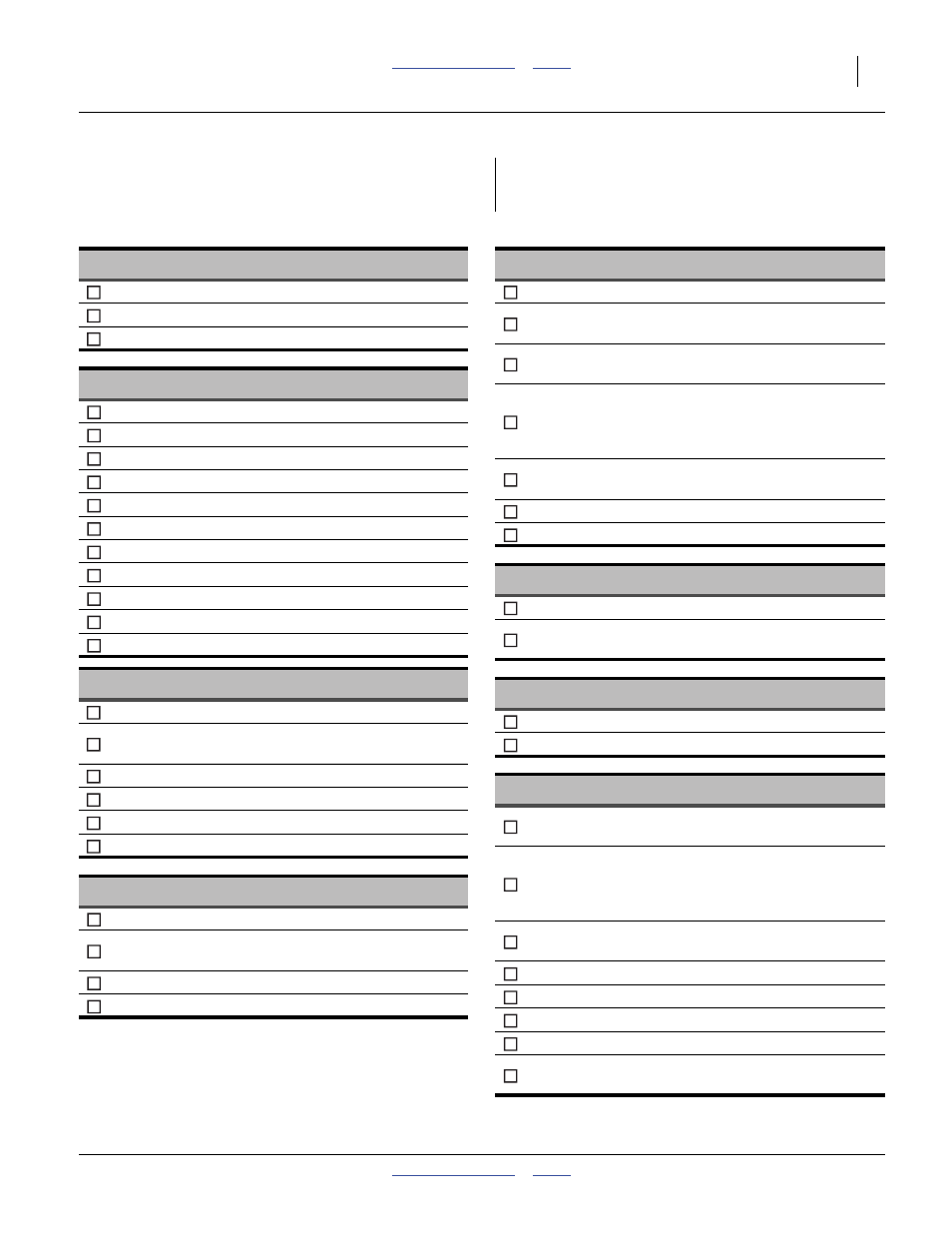

Field Setup Checklist

Use the following checklist as a guide to ensure the

planter is properly setup before using.

To complete checklists, you may need to refer to the:

SRM: Seed Rate Manual (SRM), or

DICKEY-john® PM400 Console Manual

ELECTRICAL

Page

All connections made

20

Check all lights

Power up monitor. Watch for diagnostics.

PM400

HYDRAULIC

Page

Tractor reservoir full

All hydraulic circuits connected

Fan direction and pressure

Raise tongue. Lift planter

Begin unfold

Re-phase fold system

Lower tongue

Unfold wings. Check for tongue lock.

Re-phase lift cylinders

Check marker operation

Inspect for hydraulic leaks

MECHANICAL

Page

Tongue height preset on 3-point

19

Set tractor 3-point hitch to “depth control”

operation (and not load control)

44

Side to side levelness at gauge wheels

Toe-in of wing frames at pull-bars

Tongue hook latch operation

24

Marker extension and disk angle set

125

AIR SYSTEM

Page

Air leaks

68

Hose routings, no sags and no pinched

hoses. (Check folded and field positions.)

Hoses fully connected

Start fan.

ROW METER DRIVE

Page

Check correct seed meters installed

Finger meters: check correct fingers and

inserts installed for crop and seed size

Correct seed plates installed for crop, seed

size and cell count.

Check all chains are lubricated, proper

tension and move freely without kinks or

tight spots (very important for even

metering)

Set Range & Transmission sprockets for

desired rate.

SRM

Seed lubricant in seed.

Check lids secure.

34

FERTILIZER

Page

Check lid closed and sealed.

Set variable rate gearbox for calibrated

rate.

SRM

TREATMENT (Option)

Page

Set meter adjusters to calibrated rate.

SRM

Check lids secure.

ROW UNITS

Preset depth handles to 7 holes showing

above “T”

Preset down force springs. If no optimal

setting has been developed, use 1st notch

(lightest) setting for most conditions, 2nd

notch otherwise.

Set all unit mounted coulters (Option) to

opener blade depth or slightly deeper.

Check coulter alignment to row.

Check closing wheel alignment.

62

Set press wheels.

Check scraper gaps (option).

55

Check action and contact of side depth

wheels.

55