Brake operation, Service brake operation, Single-line hydraulic brake operation – Great Plains NTA2007 Operator Manual User Manual

Page 48: Dual-line air/hydraulic brake operation, Warning

44

NTA607 or NTA2007

Great Plains Manufacturing, Inc.

166-372M

2012-01-05

Brake Operation

Main transport wheel brakes are standard on model

NTA607. Brakes are not standard on model NTA2007.

There are brake shoe pairs on each of the four forward

main transport wheels. The shoe pairs are operated by

an air system on the drill. The “service” or “trailer brake”

system is controlled by the tractor. It is connected to the

tractor with a single hydraulic line or two air lines.

See also:

page 28 - “Brake Hook-up (Option)”

page 106 - “Brake Troubleshooting (Option)”

page 123 - “Brake Maintenance (Option)”

Service Brake Operation

If optional brakes are installed and connected, the

hydraulic/hydraulic or air/hydraulic systems automatically

work in conjunction with the tractor’s own brakes.

Application and release of tractor brakes during tractor

motion applies and releases the service brake system on

the drill.

Know Your Tractor Systems:

Application of tractor Parking and/or Emergency brakes may

or may not operate the drill service brake system, depending

on the design of the tractor systems.

Consult your tractor manual for details on when remote

brake ports are engaged and released. Note any

variance from general behaviour in the table at right.

Make sure the tractor operator knows when drill brakes

are engaged and released.

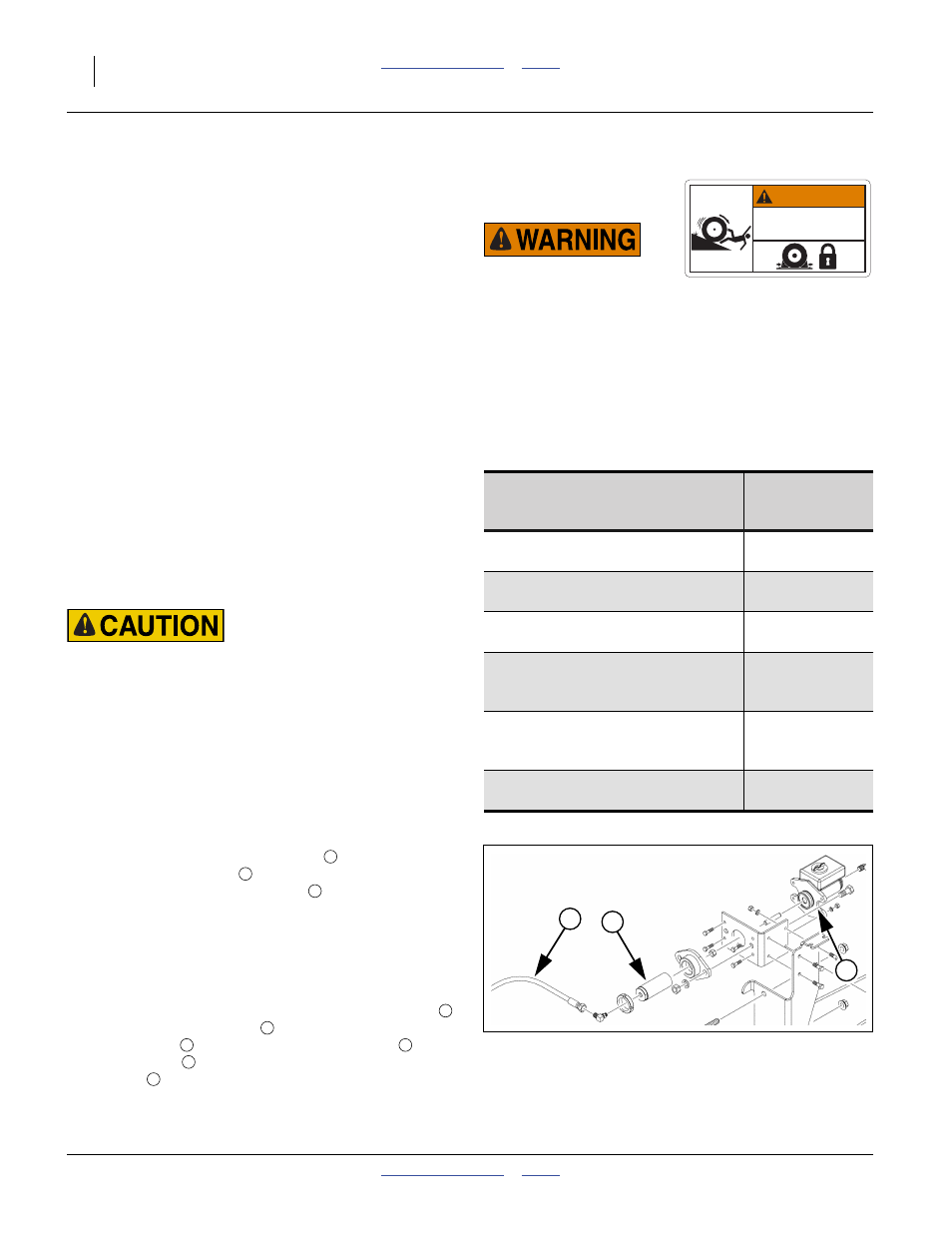

Single-Line Hydraulic Brake Operation

In this system, a single hydraulic line

from the tractor

operates a de-intensifier

cylinder on the drill, which is

coupled to the drill master cylinder

. The drill brake

hydraulic lines are separate from the tractor’s line.

With the hydraulic/hydraulic system, braking is

immediately available when the tractor hydraulic system

is active.

Dual-Line Air/Hydraulic Brake Operation

In this system, the “supply” (yellow or blue coded) line

charges a reservoir air tank

on the drill. The “service”

(red coded) line

meters air from the reservoir

to a

booster cylinder

, which operates the drill’s hydraulic

brake lines

.

Roll-Away Hazard:

Block tyres with wheel chocks before unhitching drill. The

parking jack is not a sufficient restraint for a drill parked on

unlevel ground. An unsecured drill could roll away, causing an

accident resulting in death, injury and substantial property

damage.

Both versions of the service brake system to the tractor are

spring-release on the drill. Drill braking is released shortly

after unhitching the drill.

WARNING

848 760C

ROLLING HAZARD

To avoid se ious injury or dea h from free ol ing mach ne:

•

Use provided chock b ocks to chock cart t res in

direction of grade when machine is parked

•

Chock both sides of wheel f grade s undetermined

Tractor

Braking-

Related Event

Typical Trailer

Brake Port

Response

Record How

Your Tractor

Operates

Normal tractor

braking

Activates trailer

brakes

Differential

tractor braking

Reduced trailer

braking

Tractor Parking

Brake

Activates trailer

brakes

Tractor

Emergency

Brake

Tractor

transmission to

Park

No effect on

trailer brakes

Figure 33

Hydraulic/Hydraulic Brakes

31232

1

2

3

1

2

3

4

5

6

5

7

8