Marker adjustments, Marker tension adjustment – Great Plains NTA2007 Operator Manual User Manual

Page 103

Great Plains Manufacturing, Inc.

Adjustments

99

2012-01-05

166-372M

Marker Adjustments

Review “Marker Safety Information” on page 62 before

adjusting markers. There are four operating adjustments

for markers:

• Marker Extension: (page 100)

Once set for a specific row spacing, this only needs

periodic checking to ensure the clamp is secure.

• Marker Tension: (below)

You may want to adjust the spring tension to ensure

the markers track uneven ground, and do not drag

excessively when markers are folded.

(below) Even if your row spacing rarely changes, you

may need to adjust disc angle for soil conditions and

planting speed.

• Marker Speed: (page 101)

Once initially set by your dealer, this rarely needs

modification.

There are also two maintenance items for markers:

“Marker Hydraulic Bleeding” on page 134

“Marker Shear Bolt” on page 134

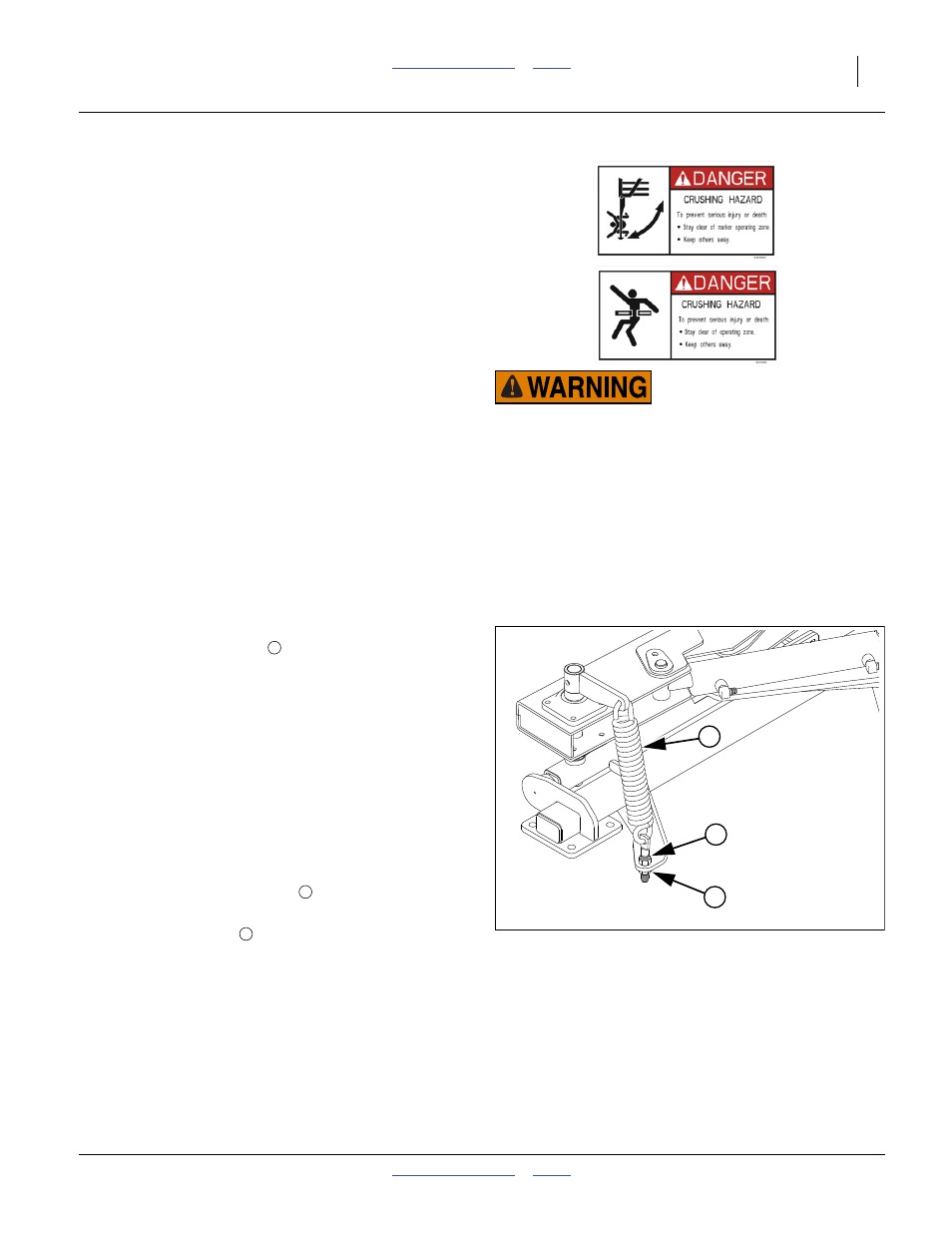

Marker Tension Adjustment

Refer to Figure 82

The strength of the mark is a function of marker arm

weight at the disc. A spring

behind the pivot assembly

acts against some of that weight. The spring is

adjustable, and may be used to increase or decrease

force at the marker disc.

The suggested initial marking force is 23 kg (50 lbs.). For

marking forces up to this value, use the weighing scale

included with the drill to lift the extended marker disc.

To adjust the marking force:

1.

Fold the markers (page 62). This minimizes spring

tension for adjustment.

2.

Set the marker hydraulic circuit to Neutral.

Shut off the tractor.

3.

Loosen the eye bolt jam nut

(on the top side of the

bracket).

4.

Turn the adjust nut

to change marking force:

Loosen this nut (relaxing the spring) to increase

marking force.

Tighten this nut (tensioning the spring) to decrease

marking force.

5.

Tighten the jam nut to secure the new setting.

Impact / Crush / Pinch / Sharp Object Hazards:

Make all adjustments with tractor hydraulics shut down, and

the marker circuit in Float. Keep all persons clear of both

markers and their sweep arcs when testing adjustments. The

marker that moves may not be the one expected. A folding or

unfolding marker is a crushing hazard, and moving sharp

object hazard, that can cause serious injury or death. It has

multiple pinch points.

Note: If the marker spring force is set too low, the marker

may fail to return to its cradle when folded.

Figure 82

Right Marker Tension Spring

31198

1

2

3

1

2

3