Lift lock troubleshooting – Great Plains NTA2007 Operator Manual User Manual

Page 109

Great Plains Manufacturing, Inc.

Troubleshooting

105

2012-01-05

166-372M

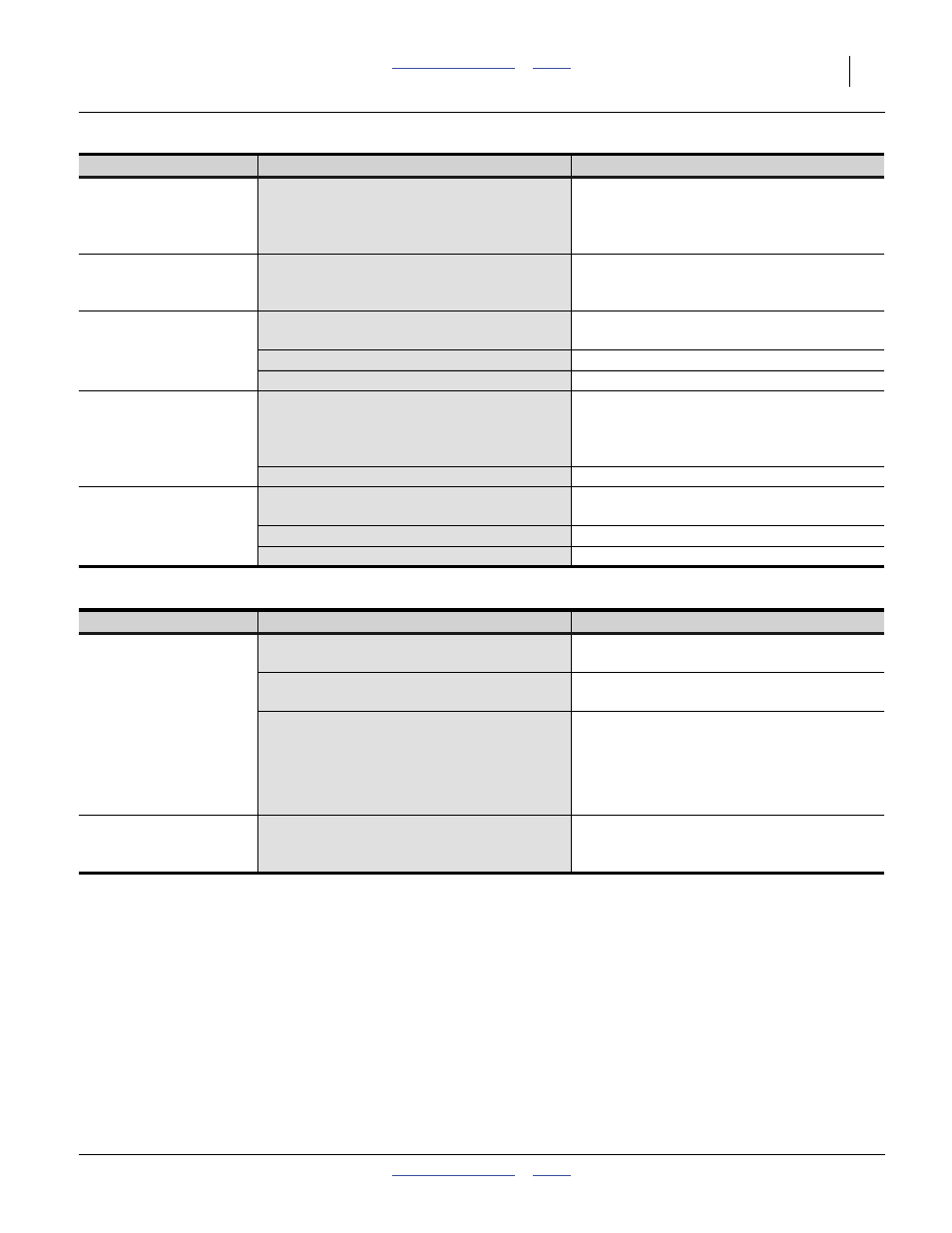

Lift Lock Troubleshooting

Front of openers

dropping too low in

hard or minimum-till

conditions

Coulters set too deep

Raise opener frame (page 86).

Pressure gauges show

pressure when

openers are raised

Hydraulic hoses not routed correctly

between pressure control valves and opener

lift cylinders.

See hose routing diagrams beginning on

page 158.

Hydraulic marker

functioning improperly

Air or oil leaks in hose fittings or

connections.

Check all hose fittings and connections for

air or oil leaks.

Low tractor hydraulic oil level.

Check tractor hydraulic oil level.

Loose or missing bolts or fasteners.

Check all bolts and fasteners.

Marker disc does not

mark

Marker counterbalance spring set too high,

and not allowing disc to drop into field

depressions (or mark on flat ground at

extreme spring settings)

Reduce counterbalance spring force.

Disc orientation not ideal for conditions

Reverse marker disc to pull or throw dirt.

Chain Skipping or

Excess Wear

Debris/no retainer clip

Be sure retainer clip is facing in opposite

direction of chain travel (page 111).

Excess slack

Adjust chain slack (page 111)

Sprockets not aligned

Adjust sprockets on shafts.

Problem

Causes

Solutions

Pawl Engaged After

Unfold

Lock cylinder not retracted.

Perform an unfold operation (page 36) to

retract lock cylinder.

Pawl held by lift lug.

Perform a lift operation (page 41) to move

lug and free pawl.

Pilot-operated check valve not activated.

1.

Extend Lift circuit.

2.

Extend Fold circuit.

3.

Temporarily increase pressure in both

down-pressure and weight transfer

circuits.

Implement Lowered

After Folding; Pawl Not

Engaged

Implement was not fully raised prior to

lowering

Problem

Causes

Solutions