Brake drum maintenance, Brake drum resurfacing, Re-mount hub and drum – Great Plains NTA2007 Operator Manual User Manual

Page 135

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

131

2012-01-05

166-372M

Brake Drum Maintenance

Refer to Figure 120

45. Inspect the shoe surface (the inside rim). Normal

appearance is dull gray, with no more than light

scoring and light wear.

One or two light score marks are not cause for

resurfacing or replacement. If there are any

questions concerning the condition of a drum,

consult an expert.

Replace or resurface a drum that is heavily scored,

worn to more than 0.51 mm (0.020 inch) oversize, or

has 0.38 mm (0.015 inch) or greater run-out.

Brake Drum Resurfacing

46. A standard drum lathe is suitable for machining the

shoe surface.

When removing surface, do not exceed the

maximum diameter cast in the brake drum.

47. Be sure to remove any metallic chips and

contamination resulting from drum machining.

Re-Mount Hub and Drum

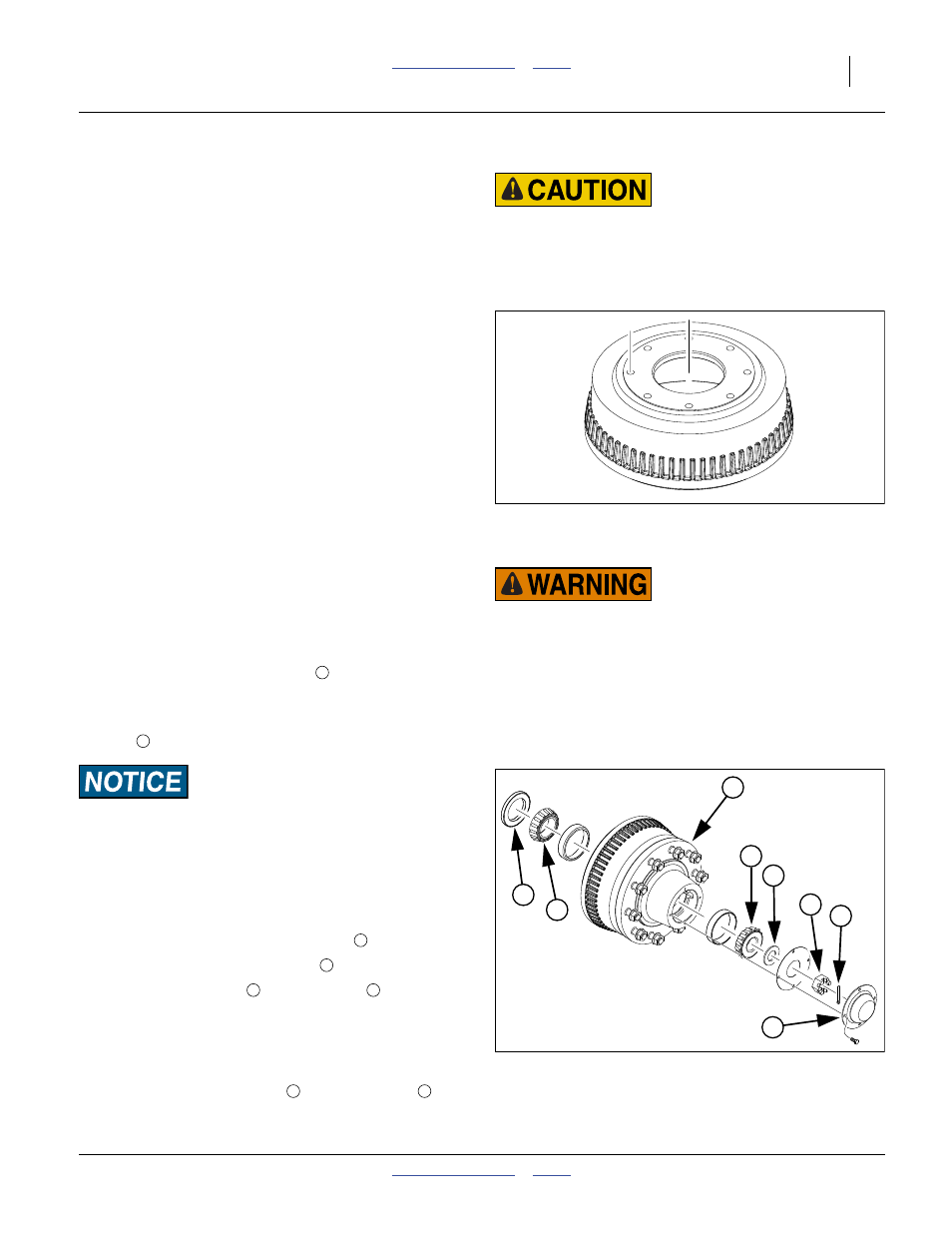

Refer to Figure 121

48. Re-pack any bearings removed.

49. If replacing inner bearing seal

, orient it with the

seam side out (away from bearing). Seat the seal so

that it is completely inside the narrow diameter of the

hub, and close to, but not touching the bearing

cup

.

Equipment Damage Risk:

When installing seals, carefully align them so they are

concentric with the shaft hole. Apply insertion force across the

entire face, or at least equally along the entire outside

diameter (as close to the seal O.D. as possible). Seals are

hollow metal structures and are somewhat fragile. The are not

intended to be in contact with the bearings.

50. Carefully place drum/hub assembly

on spindle.

51. Insert re-packed outer bearing

.

52. Add spindle washer

and castle nut

.

53. Tighten nut until drum/hub does not turn freely.

Loosen nut

1

⁄

6

turn, and as much looser as needed

to align hole in spindle (not shown) with notches in

nut.

54. Secure nut with cotter pin

. Install dust cap

.

Brake Failure Hazards:

Remove chips. Do not re-use heavily damaged or worn-out

drums. Failure to remove chips can cause bearing failure,

brake failure or wheel/spindle separation. Heavily scored,

worn or oversized drums can reduce brake performance or

cause loss of braking. This could result in death, serious

personal injury, or property damage.

Figure 120

Brake Drum

29635

Non-Asbestos Fibres and Metal Dust Hazards:

Wear a respirator equipped with a HEPA filter approved by

NIOSH or MSHA when grinding or machining brake drums.

In addition, do such work in an area with a local exhaust

ventilation system equipped with a HEPA filter.

1

2

Figure 121

Re-mount Hub and Drum

31378

1

2

3

4

5

6

7

8

3

4

5

6

7

8