Great Plains NTA2007 Operator Manual User Manual

Page 132

128

NTA607 or NTA2007

Great Plains Manufacturing, Inc.

166-372M

2012-01-05

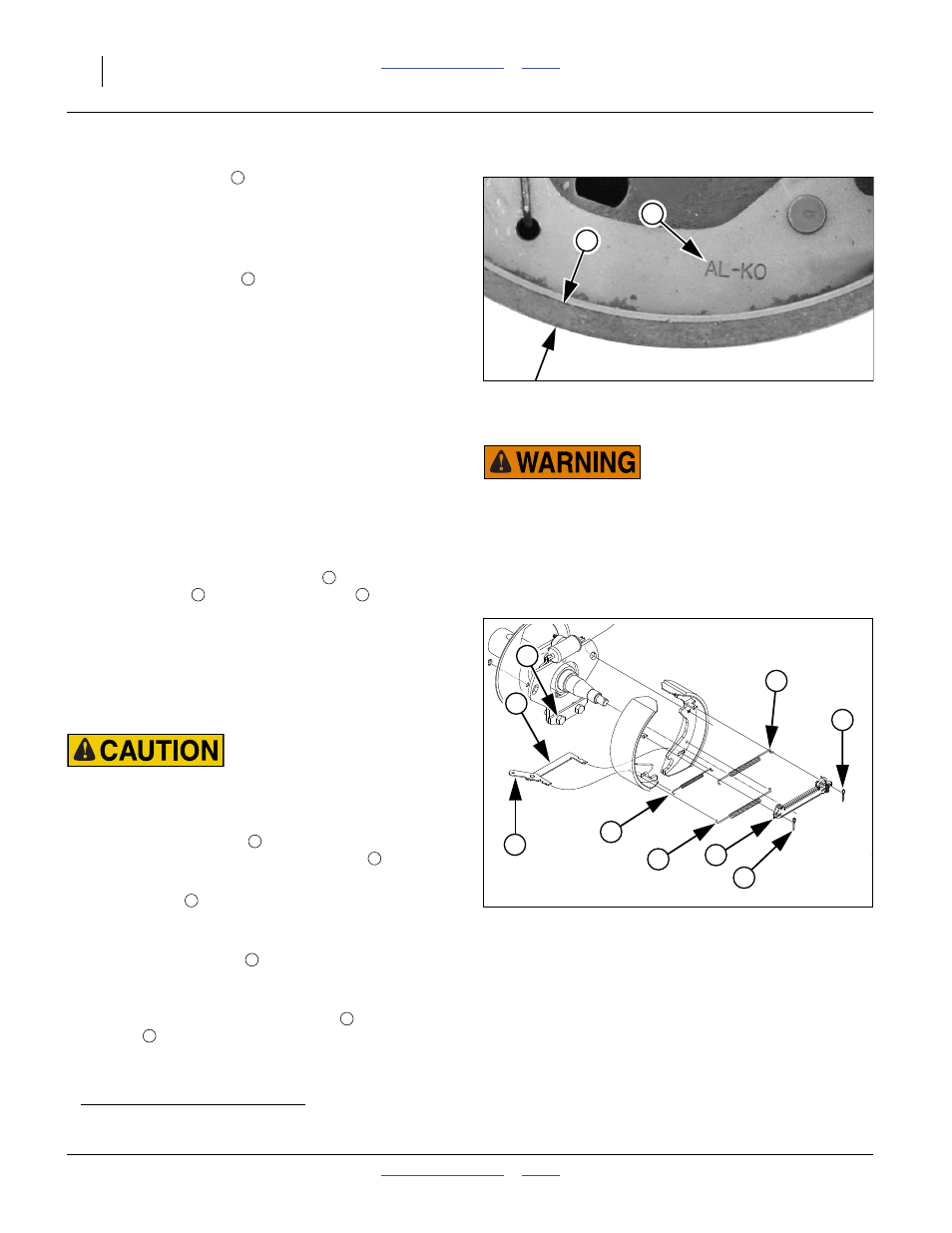

Refer to Figure 115

14. Inspect brake shoe

origin. See Warning at right.

Great Plains supplied shoes are stamped “AL-KO”

on the web face and have bonded linings.

15. Clean brake dust from assembled parts, and from

individual parts as removed.

16. Inspect brake linings

. Check for 1.6 mm (

1

⁄

16

in.)

minimum thickness (exclude thickness of shoe pad).

Check for absence of grease, contamination, deep

scores, chipping, or excessive heat fractures.

Hairline heat fissures are not unusual and do not

require shoe replacement.

17. Inspect brake shoe retaining and operating

hardware. Check for wear or damage to holes, pins

and springs. Check for weak springs. Springs must

completely retract shoes when brakes are released.

Note: Sound practice is to replace springs when

replacing brake shoes.

18. Check wheel cylinder for evidence of leaks.

If no parts need replacing, skip to step 48.

Refer to Figure 116

19. Remove self-adjuster cotter pins

. Release self-

adjuster pawl

and remove adjuster

.

20. As necessary, disassemble adjuster for cleaning.

Inspect adjust pawl and rack for wear and damage.

Great Plains recommends replacing the entire

adjuster if any parts are worn or damaged.

21. Apply thin film of Lubriplate® 110 or similar to self-

adjuster.

Brake Slippage Hazard:

Do not allow any lubricants to come in contact with new brake

linings.

22. Release upper spring

between shoes (was under

self-adjuster), and release lower spring

between

shoes.

23. Loosen nuts

on lower shoulder bolts. Push brake

shoes outward at bottom (to allow removal of hand

brake

a

arms).

24. Release lower spring

between hand brake arms.

If this spring differs from the shoe springs, set the

parking brake spring aside.

25. Remove hand brake arm assembly

. Place

spring

with it.

a. The hand/parking brake feature is not used on Model NTA607 or NTA2007 drills.

8

9

Part Failure Hazard:

Do not substitute parts. Incorrect or substandard parts can

cause brake malfunction or failure, resulting in death, serious

injury or property damage. Always re-assemble brakes with

either the removed parts (if serviceable) or Great Plains parts

as specified in the Parts Manual (166-372P).

Figure 115

Brake Shoe ID & Thickness

29643

8

9

1

2

3

Figure 116

Brake Spring Removal

29642

1

2

7

3

5

4

6

8

9

4

5

6

8

9

8