Adjusting disk contact, Disk scraper adjustments – Great Plains NTA2007HD Operator Manual User Manual

Page 95

Great Plains Manufacturing, Inc.

Adjustments

91

04/04/2011

166-283M

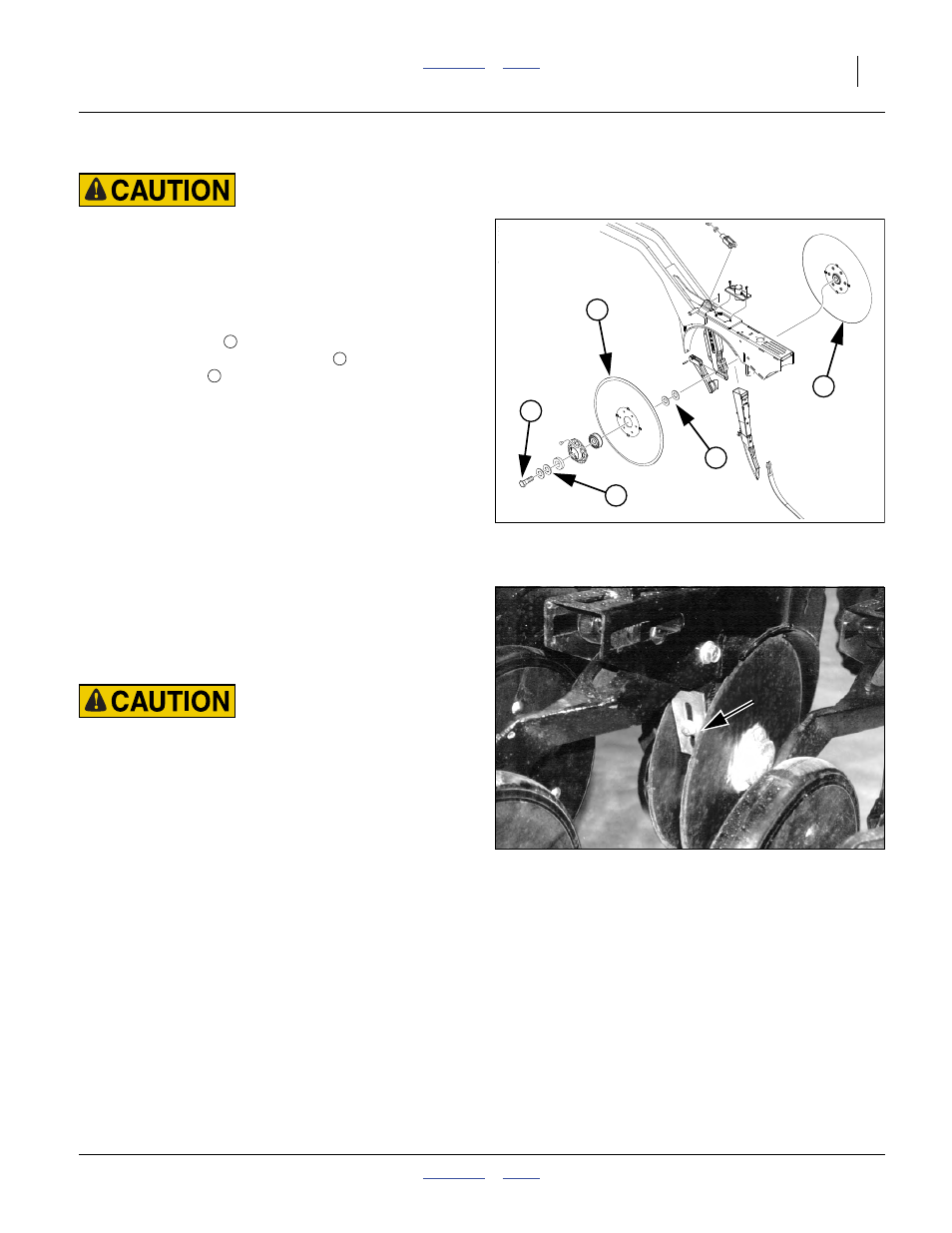

Adjusting Disk Contact

Sharp Object Hazard:

Use caution when making adjustments in this area.

Row unit disk blades may be sharp.

Refer to Figure 77

1.

Unfold implement. Configure implement for mainte-

nance lift lock (page 105).

2.

Remove the bolt

retaining the opener disk on one

side. Carefully remove the blade

, noting how

many spacers

are outside the disk and how many

are inside the disk. Do not lose the hub components

and spacers.

3.

To reduce the spacing between the disks (the normal

case), move one spacer washer from the inside to

the outside.

Note: When installing new blades, it is generally neces-

sary to move outside spacers back inside after both

disks are mounted.

4.

Re-assemble and check disk contact.

Disk Scraper Adjustments

Disk scrapers are optional. See page 143 ordering infor-

mation and page 164 for installation. To keep opener

disks turning freely, dirt scrapers are mounted between

disks to clean as disks rotate.

Sharp Object Hazard:

Use caution when making adjustments in this area.

Row unit disk blades may be sharp.

Refer to Figure 78

As field conditions vary, scrapers may need to be

adjusted. In damp conditions, lower scrapers. If openers

are not turning freely, raise scrapers. To adjust, loosen

bolt and move scraper as needed.

Null4:

Figure 77

Adjusting Disk Spacers

29350

1

3

2

3

2

1

2

3

Null4:

Figure 78

Opener Disk Scraper

26463