Great Plains NTA2007HD Operator Manual User Manual

Page 103

Great Plains Manufacturing, Inc.

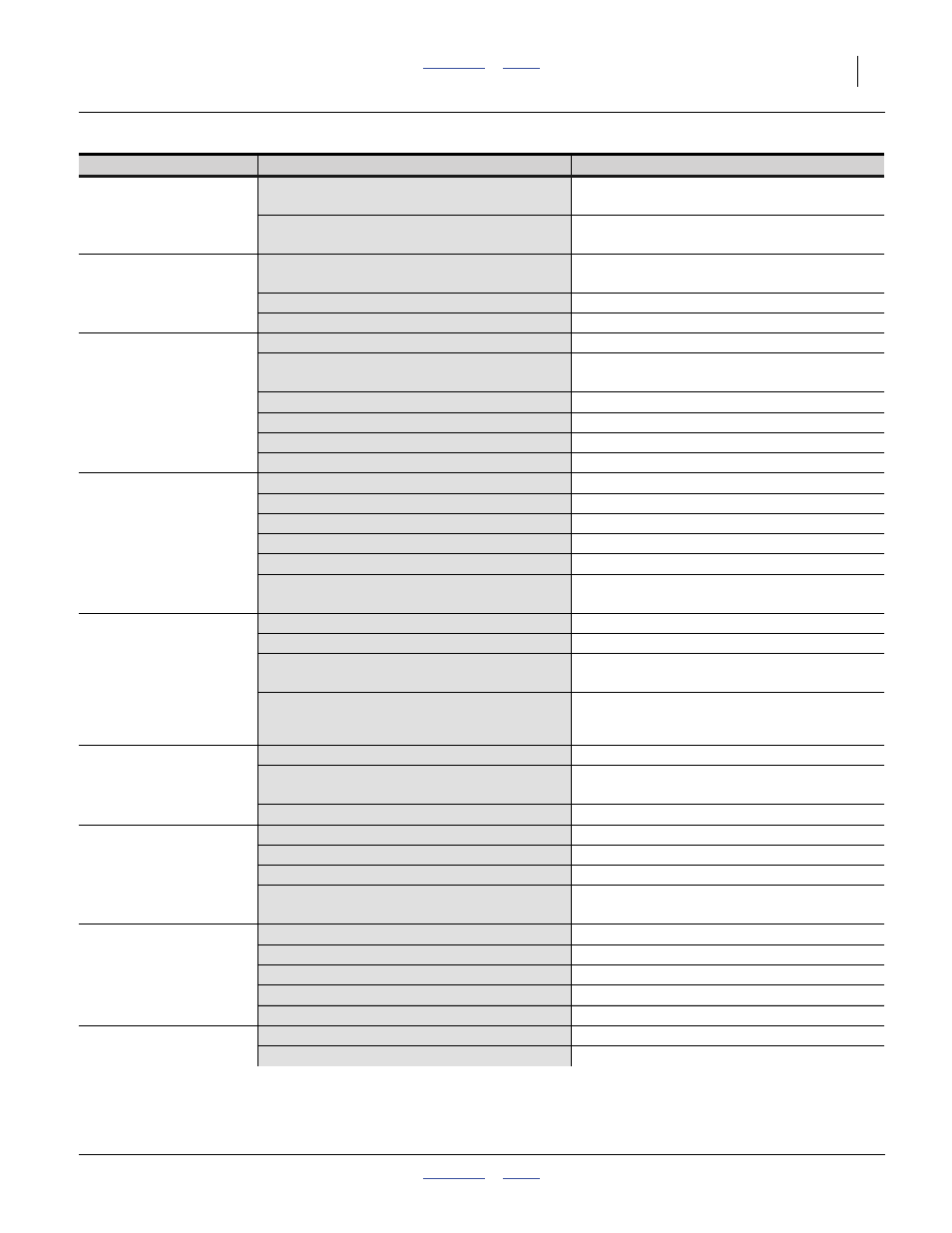

Troubleshooting

99

04/04/2011

166-283M

Planting too much

(some rows)

Dividers damaged or missing in towers.

Disassemble tower turrets. Replaced dam-

aged or worn parts.

Worn/damaged flute “stars” in meter.

Inspect empty meter from above. Remove

meter from below and repair.

Uneven seed depth

Excessive field speed

Slow down. Check Seeding Rate Chart for

correct maximum field speed.

Air drill not level

Check leveling instructions, page 129.

Planting conditions too wet

Wait until drier weather.

Uneven seed spacing

Excessive field speed.

Reduce field speed.

Drill not level

Check level (page 129) and weight transfer

(page 85).

Planting conditions too wet.

Wait until drier weather.

Seed-Lok™ building up with dirt.

Damaged or missing seed flaps.

Replace seed flaps.

Partially plugged opener seed tube.

Expose bottom of seed tube and clean out.

Opener disks not turn-

ing freely

Opener plugged with dirt.

Clean opener.

Planting conditions too wet.

Wait until drier weather.

Seed-Lok™ is plugging opener.

Failed disk bearings.

Replace disk bearings.

Bent or twisted opener frame.

Replace opener frame.

Partially plugged opener seed tube.

Lift up drill, expose bottom of seed tube and

clean out.

Hectares or acres

planted not correctly

reported (Area tally is

most accurate when

seeding back and forth

with markers with few

headlands and curves).

Incorrect tire size or air pressure.

Correct tire size or air pressure, page 147.

Excessive overlap or gaps between passes. Avoid overlap or gaps. Adjust marker.

Soil conditions.

Loose soil and slippage will cause variations

in acres registered.

Actual field size different.

Verify field size.

Press wheels not com-

pacting the soil as

desired

Too wet or cloddy.

Wait until drier weather or rework ground.

Inadequate or incorrect Weight Transfer

adjustment

Adjust weight transfer (page 85)

Incorrect press wheel depth.

Reset press wheel depth, page 93.

Excessive seed crack-

ing

Excessive field speed.

Reduce field speed.

Unclean seed.

Use clean seed.

Damaged, old or dry seed.

Use clean, new seed.

Fan speed too high

Use only enough speed for accurate delivery

to all rows.

Press wheel or open-

ers plugging

Planting conditions too wet.

Wait until drier weather.

Backed up with drill in the ground.

Clean out and check for damage.

Failed disk bearings.

Replace disk bearings.

Disk blades worn.

Replace disk blades.

Scraper worn or damaged.

Replace scraper.

Openers drill too deep

(Bulldozing)

Coulters set too deep

Raise opener frame (page 81).

Incorrect press wheel adjustment.

Readjust press wheel, page 93.

Problem

Causes

Solutions