Row unit spring adjustment, Disk blade adjustments, Row unit spring adjustment disk blade adjustments – Great Plains NTA2007HD Operator Manual User Manual

Page 94

90

Great Plains Manufacturing, Inc.

NTA607/2007HD

166-283M

04/04/2011

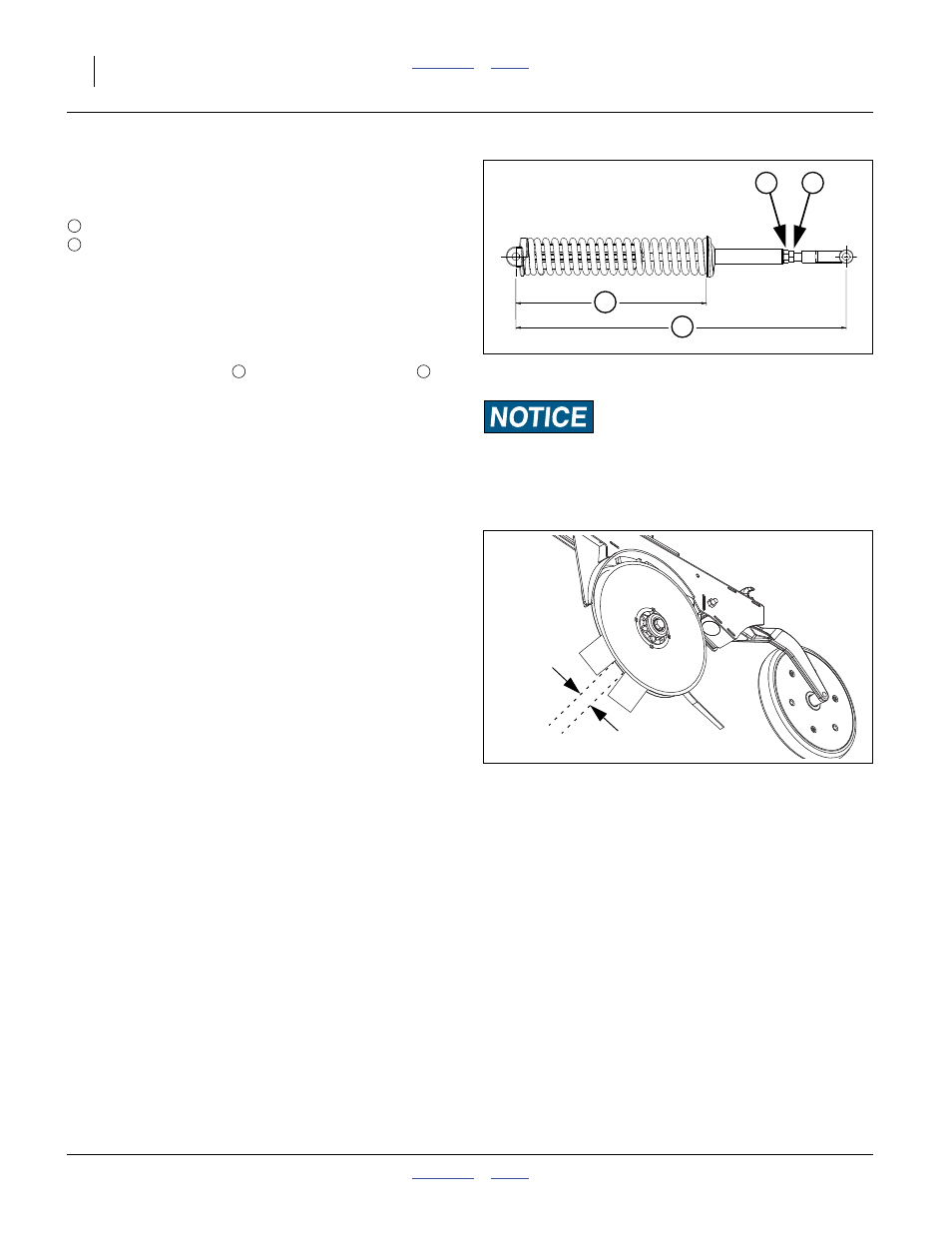

Row Unit Spring Adjustment

Row unit springs normally require no adjustment. The

factory setting for the row unit springs is:

In some unusual conditions, rows in tire tracks may need

to be set heavier.

1.

Make adjustments with the wings unfolded and the

rows lifted off the ground, so that the springs are at

full extension.

2.

Loosen the jam nut

. Rotate the adjuster nut

Shorten spring to increase down-force; lengthen

spring to reduce down-force.

For each turn of the adjuster nut, the down force at

the opener disk changes by approximately:

1.7 kg/turn (3.7 lbs/turn)

3.

Re-tighten jam nut after setting force.

Disk Blade Adjustments

Opener disk angle and stagger is not adjustable, but

disk-to-disk spacing is, and may need attention as disks

experience normal wear. Spacers will need to be reset

when blades are replaced.

Refer to Figure 76

The ideal spacing causes the blades to be in contact for

about 2.5cm (1 inch). If you insert two pieces of paper

between the blades, the gap between them should be

0 to 4.4cm (0 to 1.75in).

If the contact region is significantly larger or smaller (or

there is no contact at all), it needs to be adjusted by mov-

ing one or more spacer washers. If the contact region

varies with blade rotation, one or both blades is likely

bent and in need of replacement.

Null4:

Spring length

32.4 cm (12

3

⁄

4

in)

Assembly length

56.2 cm (22

1

⁄

8

in)

Null4:

Null4:

Machine Damage Risk:

Do not use spring lengths shorter than 29.8 cm (11

3

⁄

4

in).

It may contribute to premature parts failure not covered by

warranty.

Figure 75

Row Unit Spring

29427

1

2

3

4

4

Null4:

Figure 76

Checking Disk Contact

26395