Adjustments, Adjustments summary – Great Plains NTA2007HD Operator Manual User Manual

Page 68

64

Great Plains Manufacturing, Inc.

NTA607/2007HD

166-283M

04/04/2011

Adjustments

Adjustments Summary

To get full performance from your NTA607/2007HD drill,

you need an understanding of all component operations,

and many provide adjustments for optimal field results.

Even if your planting conditions rarely change, some of

these items need periodic adjustment due to normal

wear.

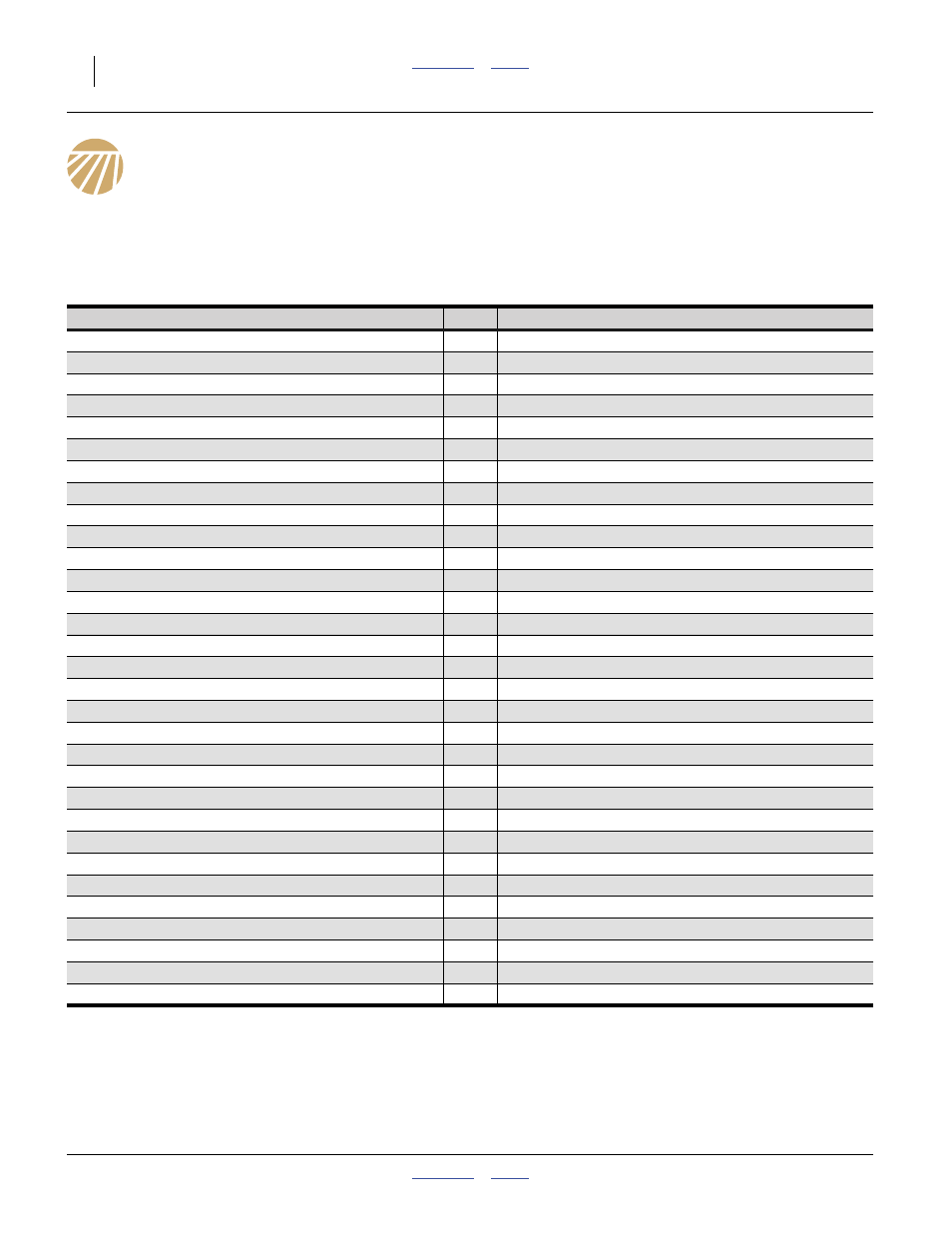

Null4:

Adjustment

Page

The Adjustment Affects

Tongue Height

Correct draft load to tractor

Frame and Wing Alignment

Planting consistency

Height Switch Adjustment

Correct off/on state of meter drive

Chain Slack

Avoidance of irregular metering and low rates

Consistent metering, and damage avoidance

Monitor Configuration

-

Primary source is DICKEY-john

®

Air System

Fan RPM

Consistent, gentle material delivery

Diverter Vane

Balancing for dissimilar materials

Material Rates

-

Primary source is Seed Rate manual 167-085B

High Rate Flute Sets

150% or 200% metering rates

Rate Range Gears

10x metering rate change

Variable Rate Gearboxes

0 to 100% of current rate range

Calibration

Correcting chart rate to your specific materials

Marker Adjustments

Marker Extension

Intended swath spacing

Marker Tension

Marking weight. Correct folding.

Marker Disk Angle and Direction

Visibility of mark

Marker Speed Adjustment

Reliable marker operation

Wing Weight Transfer Adjustment

Ensuring that wing openers operate at desired depth

Cart Weight Transfer Adjustment

Increase available weight in challenging conditions

Frame-Mounted Coulters

Row pre-furrow depth

Summary of adjustments available

Row Unit Adjustments for Series...

07HD

Opener Depth (Press Wheel Height)

Planting depth

Row Unit Down Pressure (Individual)

Planting depth uniformity in tire tracks

Opener Disk Adjustments

Seed depth, seed-to-soil contact

Inside Scrapers

Reliable disk operation

Seed Firmer Adjustments (Option)

Seed-soil contact

Press Wheel Adjustment

Effective soil coverage