Air systems overview – Great Plains NTA2007HD Operator Manual User Manual

Page 59

Great Plains Manufacturing, Inc.

Operating Instructions

55

04/04/2011

166-283M

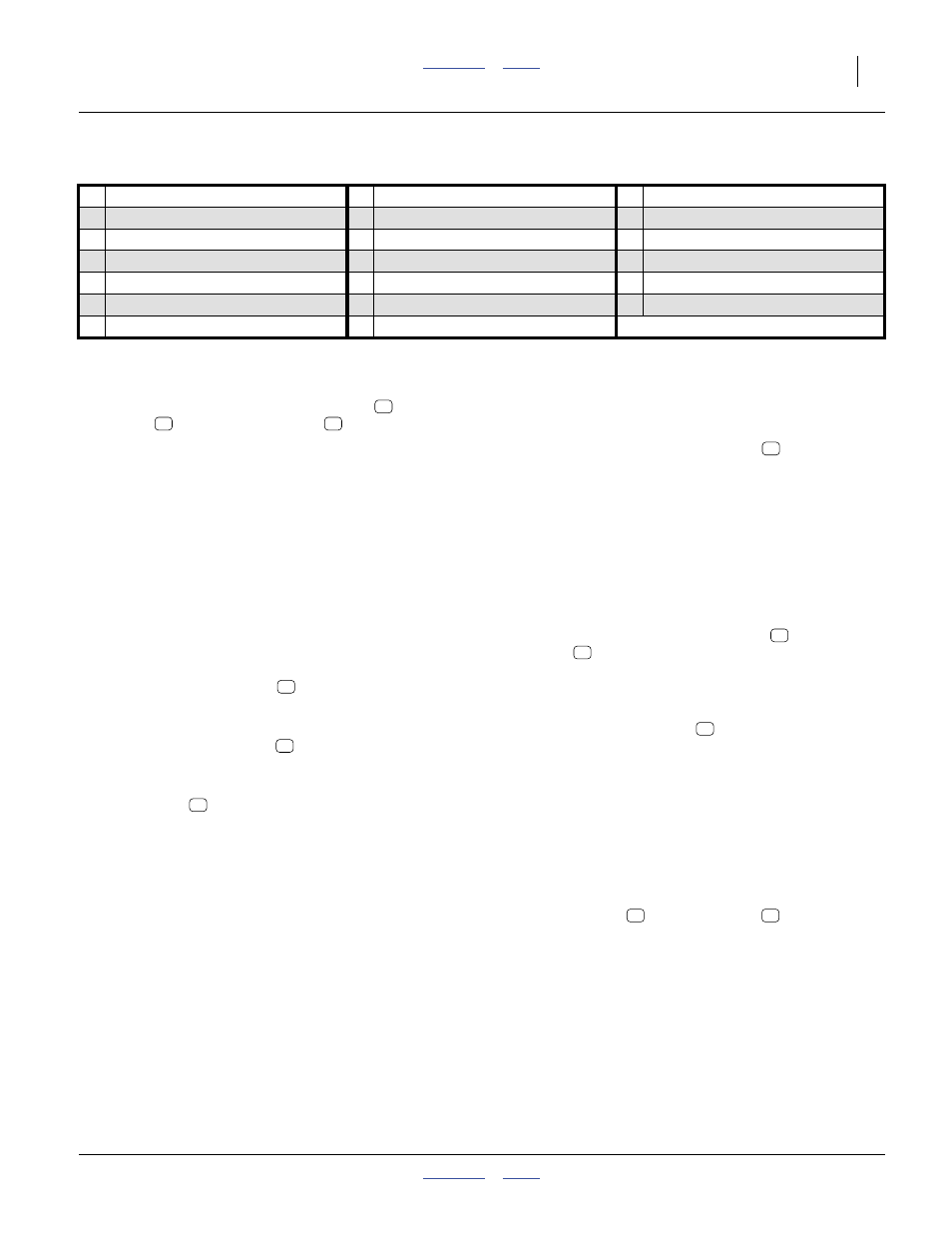

Air Systems Overview

1.

Hydraulic Fan (page 56)

The fan generates the air flow required to deliver

material to the rows. Speed is adjusted via the trac-

tor circuit. Output is monitored via rpm

, pressure

gauge

and pressure sensor

.

2.

Fan RPM Sensor (page 82)

The seed monitor reports fan rpm based on this sen-

sor. Although it is accurate for rate, it cannot detect a

fan running in reverse.

3.

Diverter Vane (page 84)

Present only on dual-hopper drills, this controls air-

flow balance between the meters. This may need

adjustment with dissimilar material metering.

4.

Manifold Pressure Gauge(s) (page 82)

There is one gauge per hopper, mounted for ease of

observation from the tractor cab. These report

whether or not the air system is within recommended

limits. On dual-hopper systems, the gauges assist in

setting the diverter vane

.

5.

Meter Inlet Manifold (page 84)

Fan air is divided (or further divided) into equal flows

for each meter inlet port

.

6.

Hopper (page 48)

Material (seed or fertilizer) flows into the top of the

seed meter

.

7.

Pressure Balance Lines

Each hopper contains an internal pressure-balanc-

ing system to equalize pressure above and at the

base of the material.

8.

Hopper Pressure Sensor

This sensor signals the seed monitor, which can

alarm if the hopper pressure goes out of limits. A

dual hopper drill has two sensors.

9.

Seed Meter

The meter combines material with air flow. It also has

features for rate Range, calibration and clean-out.

10. Flute Shaft (page 163)

Two (and optionally; three or four) sets of flute “stars”

control the flow of seed from the hopper into the air

streams.

11. Flute Shaft RPM Sensor (page 71)

This shaft encoder provides metering rate data, stop-

page alarms, and is used by the optional Variable

Rate Kit to control metering rate.

12. Meter Outlet Ports

Material falls from the meter flutes

streams flowing from inlet manifold to outlet ports.

Each port is a separate compartment.

13. Single-Shoot Y-Tube

A two-hopper drill may optionally have the output of

both meters combined into a single stream to a sin-

gle set of towers. The flows combine at Y-tubes

behind the meters.

14. Primary Seed Hose

Four (single-hopper/shoot) or eight (double-shoot)

hoses deliver seed from the meters

to the

towers

.

15. Distribution Tower

The riser tube and distribution rings have features to

evenly divide the primary hose material flow into

multiple secondary hose

flows. There are four

towers on single-hopper and single-shoot drills, and

eight towers on double-shoot drills.

16. Blockage Sensor

Each tower outlet port has a sensor that detects

material passage and signals the seed monitor. The

primary function of this sensor is to trigger an alarm

on flow stoppage.

17. Secondary Seed Hose

These hoses deliver material from a tower outlet port

to a seed tube

or fertilizer tube

18. Tramline Diverter (Option, page 142)

19. Opener Seed Tube

Seed from hopper I (and hopper II on single-shoot

drills) is delivered in-furrow ahead of the seed firmer.

20. Opener Fertilizer Tube (page 93)

On a dual-hopper double-shoot drill, the material

from hopper II is delivered to this tube above the

seed firmer and furrow.

1 Hydraulic Fan

8 Hopper Pressure Sensor

15 Distribution Tower

2 Fan RPM Sensor

9 Seed Meter

16 Blockage Sensor

3 Diverter Vane

10 Flute Shaft

17 Secondary Seed Hose

4 Manifold Pressure Gauge

11 Flute Shaft RPM Sensor

18 Tramline Diverter

5 Meter Inlet Manifold

12 Meter Outlet Ports

19 Opener Seed Tube

6 Hopper

13 Single-Shoot Y-Tube

20 Opener Fertilizer Tube

7 Pressure Balance Lines

14 Primary Seed Hose

15